Seed crystal processing method used for growth of high quality SiC crystals

One treatment method, high quality technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

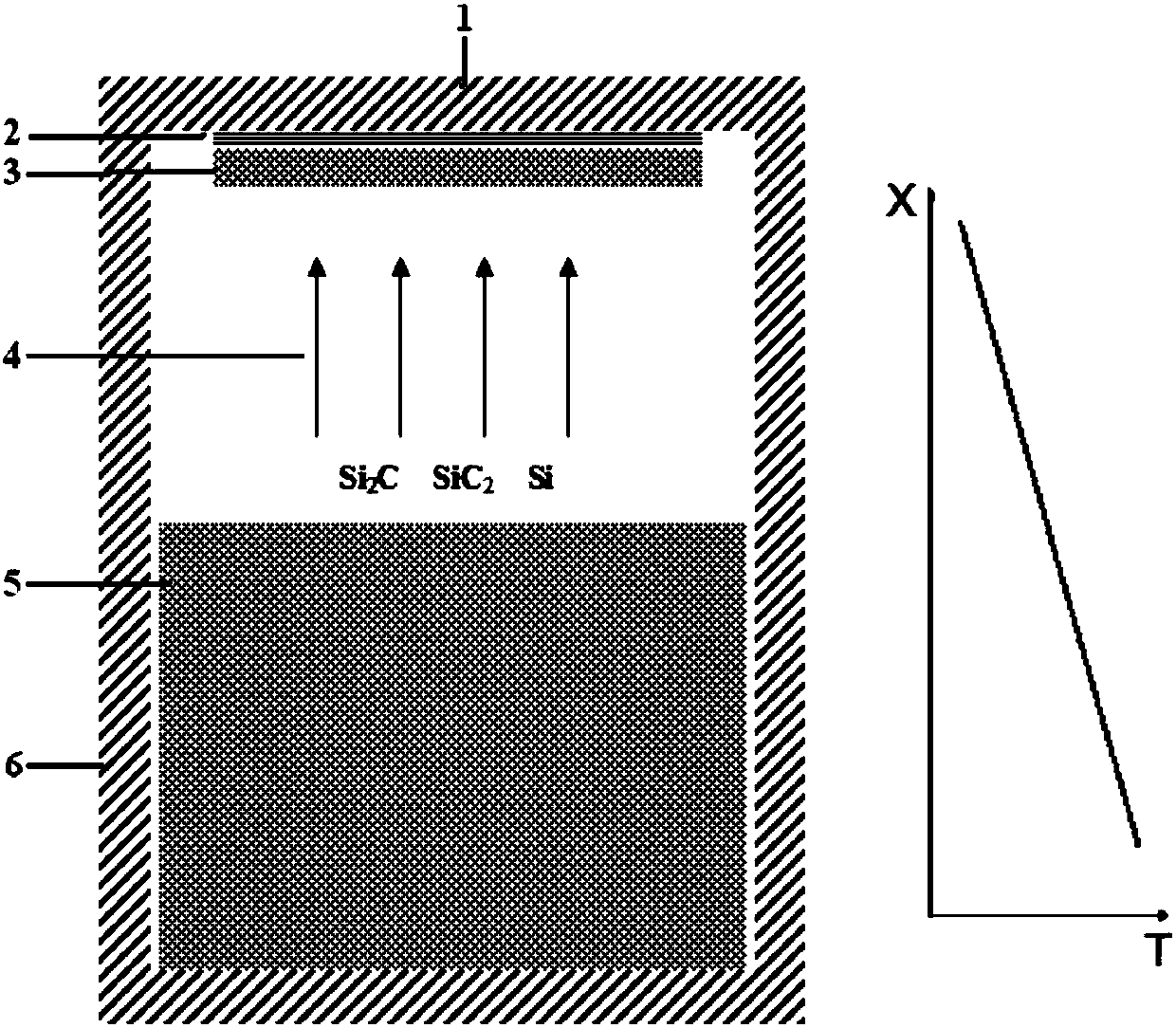

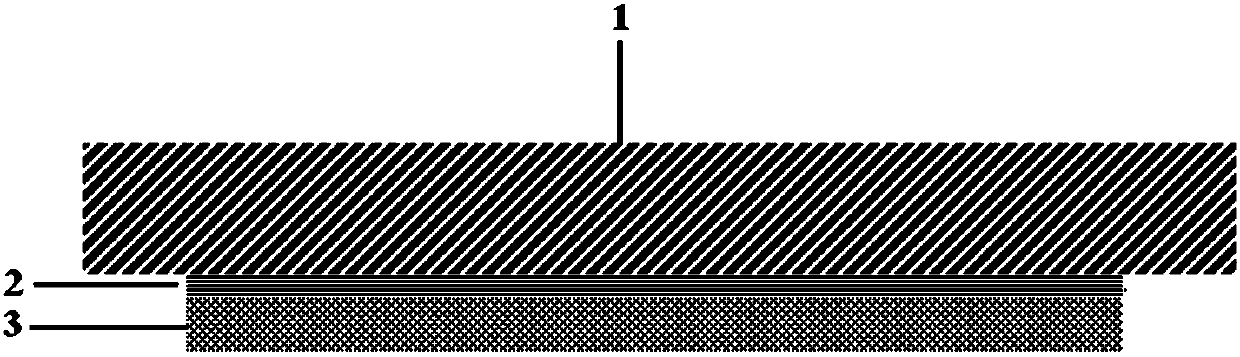

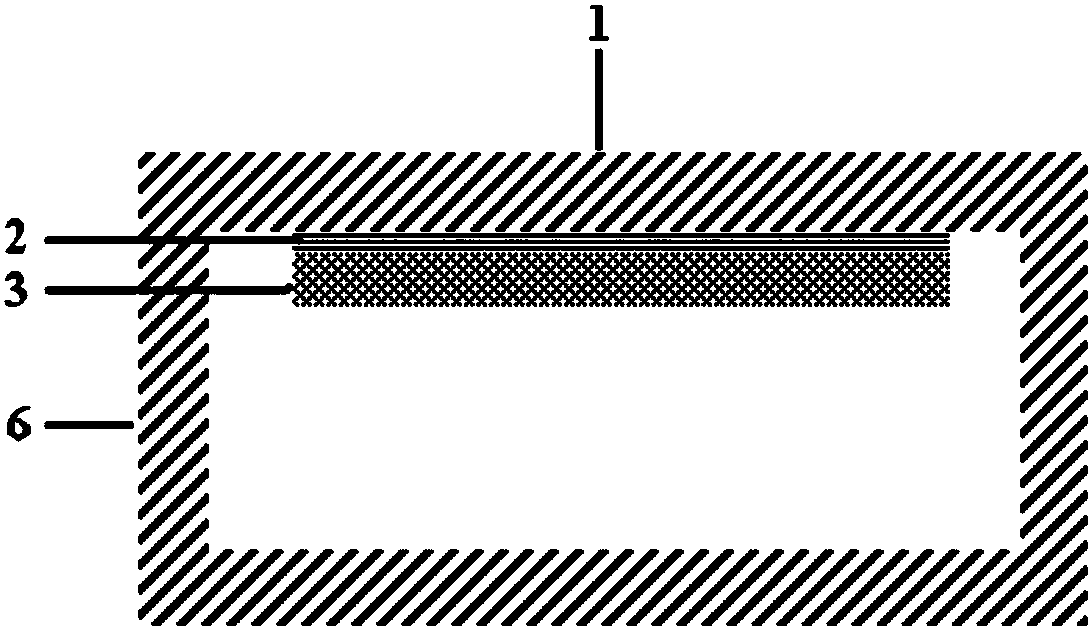

[0024] Put the 4-inch SiC seed crystal 3 bonded on the graphite holder 1 on the crucible 5 and place it in a high-temperature graphite heating furnace with good airtightness and thermal insulation, vacuumize to 5 Pa, and then fill it with Ar to 30 kPa; Then evacuate to 5 Pa, pass H2 / Ar=0.1 mixed gas to 5 kPa; take 3 hours to raise the temperature to 1750 ° C, keep the temperature for 8 hours, and then take 10 hours to cool down to room temperature.

Embodiment 2

[0026] Put the 6-inch conductive SiC seed crystal 3 bonded on the graphite support 1 on the crucible 5 and place it in a high-temperature medium-frequency induction heating furnace with good airtightness and heat preservation, evacuate to 5 Pa, and fill it with Ar to 50 K Pa; then evacuate to 5 Pa, and pass H2 / Ar=0.3 mixed gas to 8 kPa; take 4 hours to raise the temperature to 1850 ° C, keep the temperature for 7 hours, and then take 15 hours to cool down to room temperature.

Embodiment 3

[0028] Put the 6-inch conductive SiC seed crystal 3 bonded on the graphite support 1 on the crucible 5 and place it in a high-temperature medium-frequency induction heating furnace with good airtightness and heat preservation, evacuate to 5 Pa, and fill it with Ar to 40 K Pa; then evacuate to 5 Pa, and pass H2 / Ar=0.2 mixed gas to 8 kPa; take 4 hours to raise the temperature to 1800 ° C, keep the temperature for 8 hours, and then take 12 hours to cool down to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com