Zero-dimensional/one-dimensional heterostructure bismuth vanadate/zirconia nanobelt photocatalyst and preparation method thereof

A heterostructure, photocatalyst technology, applied in the field of photocatalysis, can solve the problems of unsatisfactory photocatalytic activity, reduce electron-hole recombination, etc., and achieve the effect of improving photocatalytic activity, enhancing absorption capacity, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

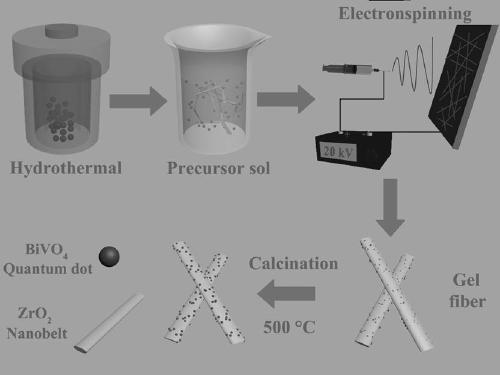

[0031] (1) Put 0.730g of sodium oleate in 80mL of deionized water and stir at room temperature for 30min to obtain sodium oleate solution A with a mass concentration of about 0.1%;

[0032] (2) Add 0.097g of bismuth nitrate and 0.080g of ammonium metavanadate into solution A, and stir at room temperature for 10~10min;

[0033] (3) Add solution A into the reaction kettle and heat the reaction in an oven at 90°C for 8 hours;

[0034] (4) Centrifuging the solution after the reaction for several times and washing the obtained substance with ethanol and deionized water several times to obtain bismuth vanadate quantum dots;

[0035] (5) Dissolve 1.0g polyvinylpyrrolidone (PVP) in a mixed solvent of 10mL N,N-dimethylformamide and 1mL deionized water and stir evenly to obtain solution B;

[0036] (6) Add 0.064g of zirconium oxychloride and 0.065g of bismuth vanadate quantum dots to solution B, ultrasonicate for 20-40min, then stir at room temperature for 2h to obtain a spinnable sol;...

Embodiment 2

[0041] (1) Put 0.730g of sodium oleate in 80mL of deionized water and stir at room temperature for 30min to obtain sodium oleate solution A with a mass concentration of about 0.1%;

[0042] (2) Add 0.097g of bismuth nitrate and 0.080g of ammonium metavanadate into solution A, and stir at room temperature for 10~10min;

[0043] (3) Add solution A into the reaction kettle and heat the reaction in an oven at 90°C for 6 hours;

[0044] (4) Centrifuge the solution after the reaction for several times and wash the obtained substance with ethanol and deionized water several times to obtain bismuth vanadate quantum dots.

Embodiment 3

[0046] (1) Dissolve 1.0g polyvinylpyrrolidone (PVP) in a mixed solvent of 10mL N,N-dimethylformamide and 1mL deionized water and stir to obtain solution A;

[0047] (2) Add 0.064g of zirconium oxychloride to solution A, ultrasonicate for 20~40min, then stir at room temperature for 2h to obtain spinnable sol;

[0048] (3) Add the prepared spinnable sol into the syringe needle for electrospinning;

[0049] (4) Calcining the fiber membrane prepared by electrospinning to obtain zirconia nanobelts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com