Preparation and application of palygorskite/Zn-Mg-Cr ternary metal oxide composite photocatalyst

A zn-mg-cr, ternary metal technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem that the adsorption capacity cannot be simultaneously Reach the maximum, it is difficult to meet the emission requirements, the number of active adsorption sites of the material is limited, etc., to achieve the effect of good removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

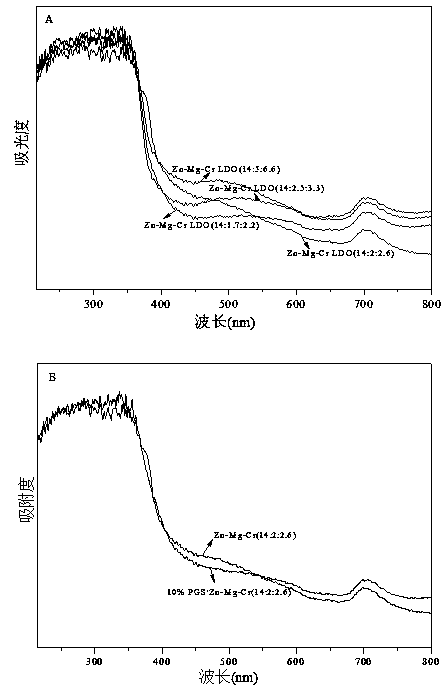

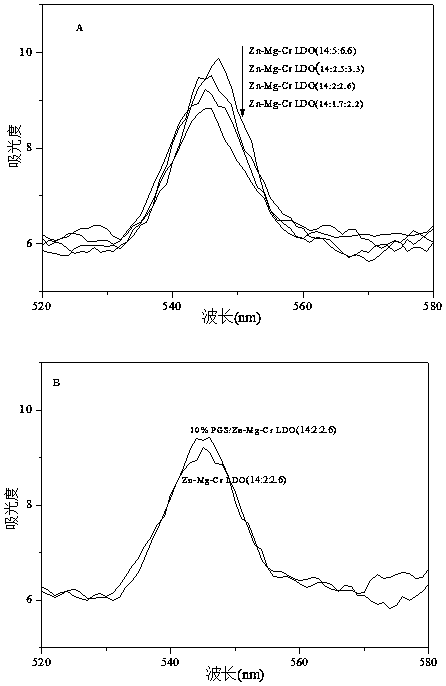

[0026] 1.3630 g ZnCl 2 , 0.2033g MgCl 2 and 0.2664 g CrCl 3 Add to 150 mL of deionized water, add 0.80 g palygorskite, stir to dissolve, then use 1.5 M NaOH and 1.25 M Na 2 CO 3 Adjust the pH of the solution to 9 with the mixed solution, move it to a hydrothermal reaction kettle at 110~130°C and keep it for 20~24 h, wait until the reaction kettle is cooled to room temperature, filter, wash the precipitate several times with deionized water, and dry; Then it was calcined at 500℃ for 4~6 h to obtain 10%PGS / Zn-Mg-Cr LDO (14:2:2.6) composite catalyst.

[0027] In this composite catalyst, ZnO, MgO, Cr 2 o 3 The mass ratio is 13.5:6.6:8.5, and the content of PGS in the composite catalyst is 10%.

Embodiment 2

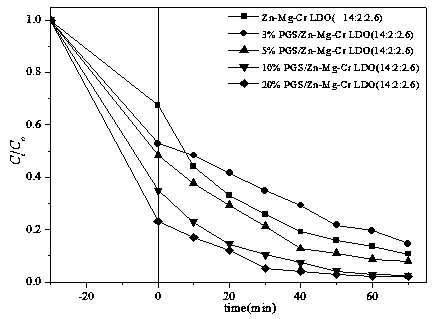

[0029]Weigh 20 mg of 10% PGS / Zn-Mg-Cr LDO (14:2:2.6) prepared in Example 1, add it to 30 mL of 10 mg / L malachite green solution, and stir for 30 min in the dark to achieve adsorption-desorption After measuring the concentration of the solution in equilibrium, a 300 W xenon lamp was used to simulate a visible light source, and the concentration of the solution was measured every 10 minutes. After irradiating for 70 minutes, according to D% = ( C 0 - C t ) / C 0 *100% calculated photodegradation rate of malachite is 97.7%.

Embodiment 3

[0031] Weigh 20 mg 10%PGS / Zn-Mg-Cr LDO (14:2:2.6) and add to 10 mL 100 mg / L Pb 2+ solution, shake at room temperature for 60 min, measure the solution concentration, according to D% = ( C 0 - C t ) / C 0 *100% calculation of Pb 2+ The adsorption rate was 98.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com