Method for synchronously realizing sewage denitrification and biogas desulfurization

A biogas desulfurization and sewage technology, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of inability to efficiently achieve simultaneous sewage denitrification and biogas desulfurization, regular replacement, and conveying pipelines Corrosion etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

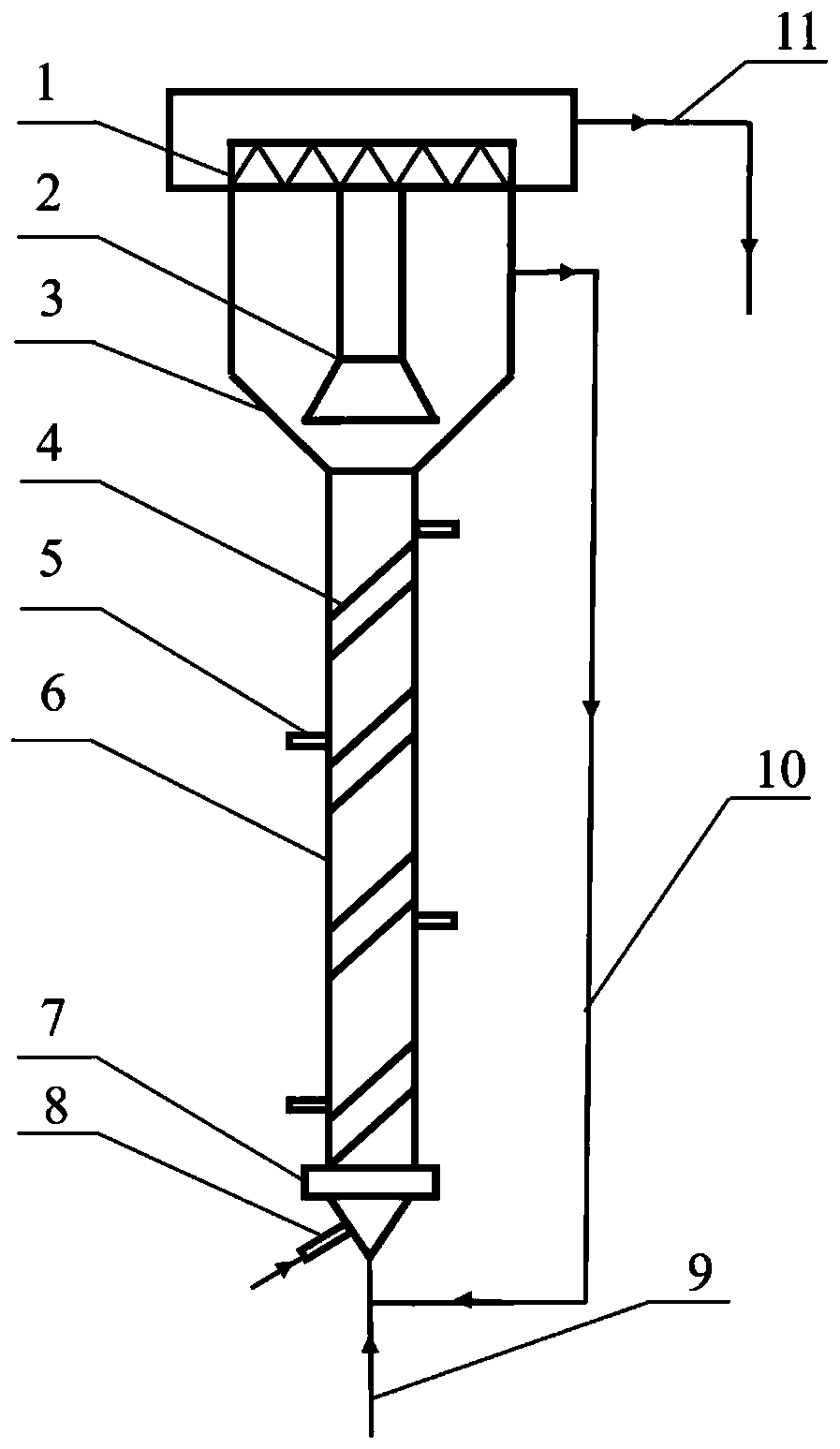

[0048] Adopt the method provided by the invention, utilize figure 1 The shown air-lift EGSB reactor (effective volume is 4.2L) treats the sewage to be treated, in which, the self-prepared simulated sewage is used as the sewage to be treated, and the composition is KNO 3 (50~600mgN / L), KH 2 PO 4 (75mg / L), CaCl 2 2H 2 O (300mg / L), MgSO 4 ·7H 2 O (200mg / L), NaHCO 3 (1050mg / L), acidic trace element materials (0.5mL / L) and basic trace element materials (0.2mL / L); wherein, the acidic trace element materials include FeSO 4 ·7H 2 O (2.085g / L), ZnSO 4 ·7H 2 O (0.068g / L), CoCl 2 ·6H 2 O(0.12g / L), MnCl 2 4H 2 O(0.5g / L), CuSO 4 ·5H 2 O (0.32g / L), NiCl 2 ·6H 2 O(0.095g / L), H 3 BO 3 (0.014g / L) and HCl (100mmol / L), basic trace element materials include NaOH (0.4g / L), NaOH 2 WO 4 2H 2 O (0.05g / L), Na 2 MoO 4 (0.242g / L) and SeO 2 (0.067g / L);

[0049] The processing process specifically includes the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com