A kind of covalent triazine framework polymer, its preparation method and application

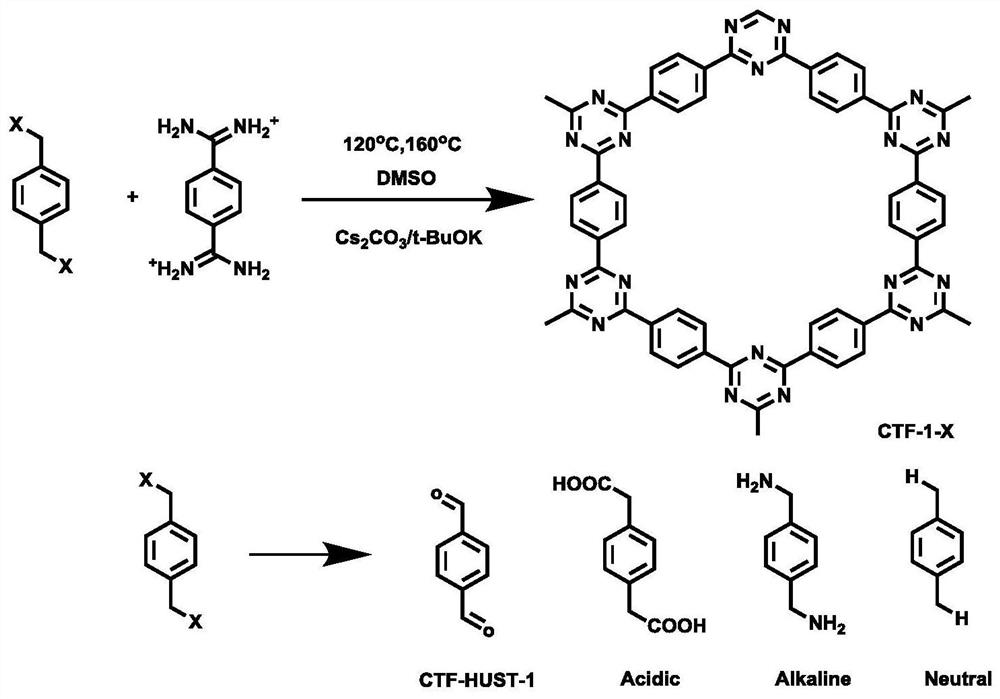

A covalent triazine and polymer technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of narrow selection range, triazine framework polymer hydrogen production In order to avoid problems such as poor performance, the method is simple, the triazine framework polymer is regular, and the effect of improving hydrogen production performance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

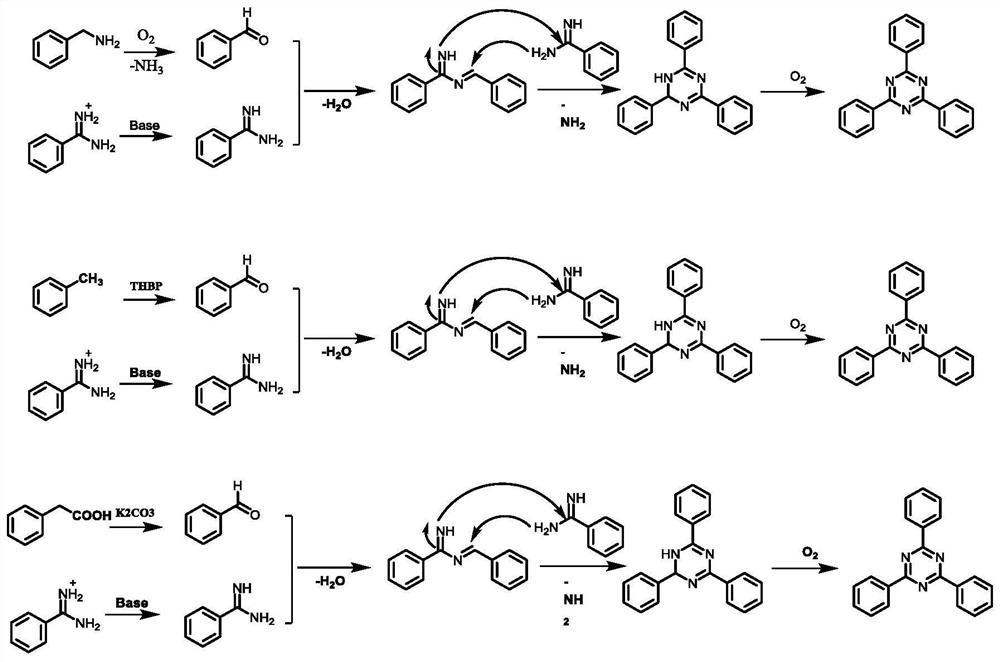

Method used

Image

Examples

Embodiment 1

[0091] A method for preparing a methyl-based covalent triazine framework material, comprising the steps of:

[0092] (1) Add a certain mass (1.0g) of p-xylene and dimethylamidine monomer with a group ratio of 2:1 in a round bottom flask of a certain volume (250.0mL);

[0093] (2) Based on step (1), potassium tert-butoxide with a ratio of 1:1 to the terephthalamidine group was added to the system, and 50 mL of DMSO was added as a solvent and stirred evenly;

[0094] (3) Based on step (2), then add 200 μL of distilled water to the flask;

[0095] (4) Start stirring based on step (3), heat, and use two gradient heating methods for heating, first heating and reacting at 100°C for 48 hours, and then heating and reacting at 160°C for 48 hours;

[0096] (5) Under the reaction conditions based on step (4), the reaction time is 96 hours. Then stop heating and stirring, and then add 50mL of ethanol to the system after the device is completely cooled. Then vacuum filter using Buchner ...

Embodiment 2

[0105] A method for preparing a covalent triazine framework material based on acetate, comprising the steps of:

[0106] (1) In a round bottom flask of a certain volume (250.0mL), add a certain mass (1.0g) of diacetic acid and a dimethylamidine monomer with a group ratio of 2:1;

[0107] (2) Based on step (1), then add a strong base such as potassium tert-butoxide in an amount of 1:1 to the terephthalamidine group into the system, add 50 mL of DMSO as a solvent and stir Uniform;

[0108] (3) Based on step (2), then add 200 μL of distilled water into the flask.

[0109] (4) Start stirring based on step (3), heat, and use two gradient heating methods for heating, the first heating reaction at 150°C for 48 hours, and then heating reaction at 160°C for 48 hours.

[0110] (5) Under the reaction conditions based on step (4), the waiting time for reaction is 96 hours. Then stop heating and stirring, and then add 50mL of ethanol to the system after the device is completely cooled. ...

Embodiment 3

[0119] A preparation method of a benzylamine-based covalent triazine framework material, comprising the steps of:

[0120] (1) Add a certain mass (1.0 g) of dibenzylamine and dimethylamidine monomer with a group ratio of 2:1 into a round bottom flask with a certain volume (250.0 mL).

[0121] (2) Based on step (1), then add a strong base such as potassium tert-butoxide in an amount of 1:1 to the terephthalamidine group into the system, add 50 mL of DMSO as a solvent and stir uniform.

[0122] (3) Based on step (2), then add 200 μL of distilled water into the flask.

[0123] (4) Start stirring based on step (3), heat, and use two gradient heating methods for heating, the first heating reaction at 100-150°C for 48 hours, and then heating reaction at 160°C for 48 hours.

[0124] (5) Under the reaction conditions based on step (4), the waiting time for reaction is 96 hours. Then stop heating and stirring, and then add 50mL of ethanol to the system after the device is completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com