Solid-liquid fermentation combined mulberry wine formula and making method

A production method and a technology of solid-liquid fermentation, which are applied in the field of food processing, can solve the problems of single taste of mulberry wine, low yield of raw materials, destruction of mulberry fruit aroma, etc., and achieve a wide range of suitability, uniform color and quality, and low acidity and sugar content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

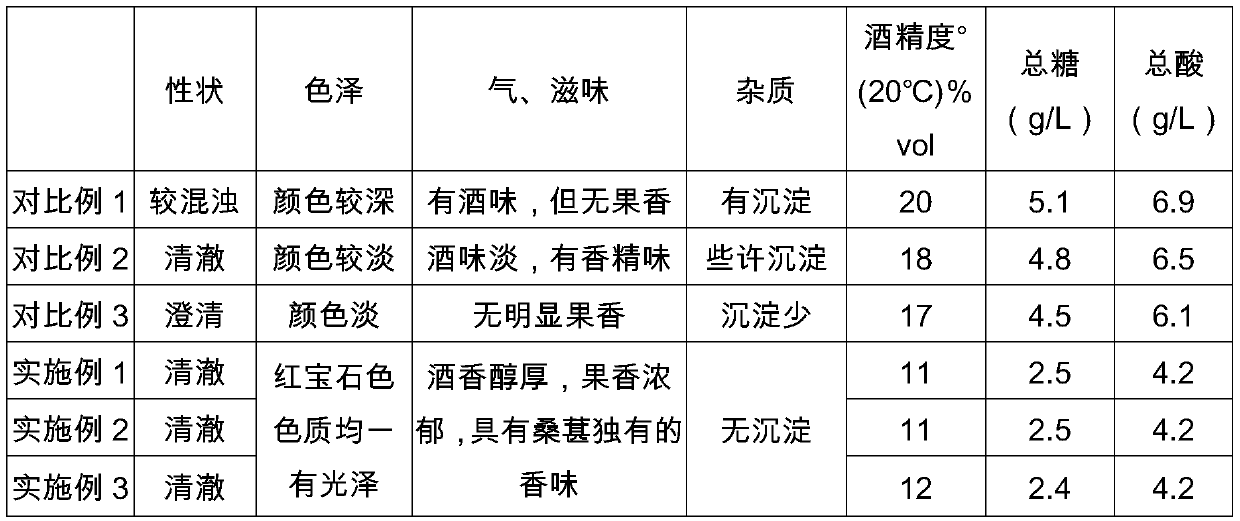

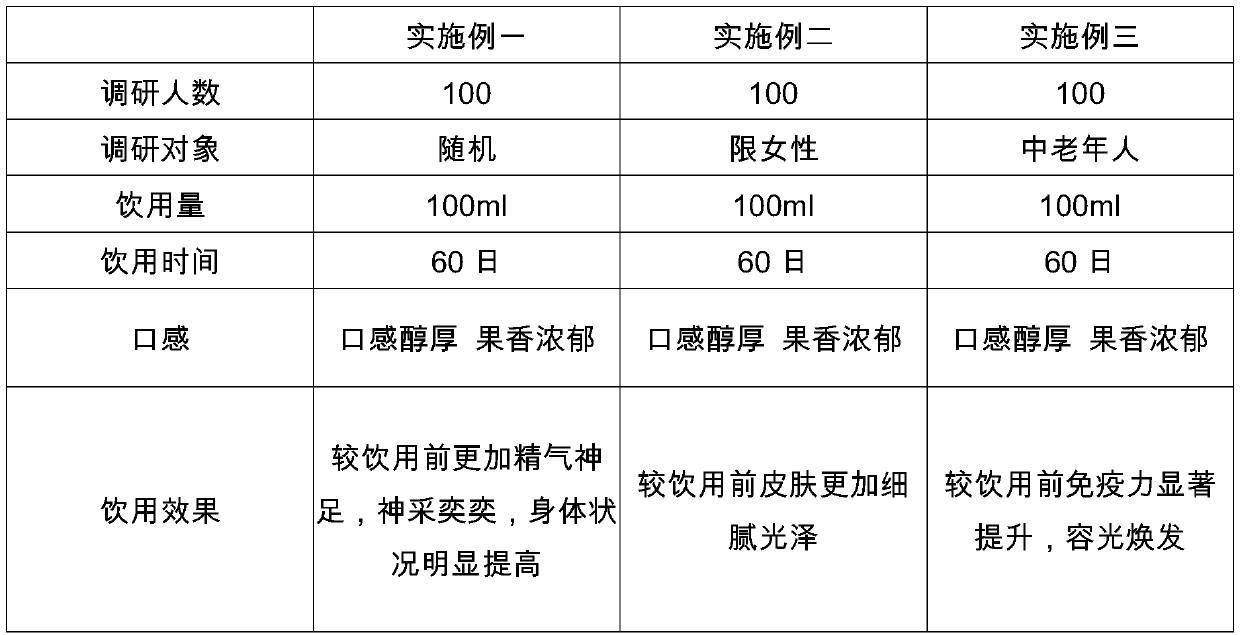

Examples

Embodiment 1

[0036] A formula of mulberry wine combined by solid-liquid fermentation is made of raw materials with the following weight components: 12 parts of mulberries, 1 part of black wolfberry, and 8 parts of black glutinous rice.

[0037] A method for making mulberry wine combined with solid-liquid fermentation, including: material selection processing, juice separation, solid-state fermentation, retort distillation, blending and mixing, and liquid fermentation;

[0038] (1) Material selection processing:

[0039] Screening and processing of mulberries: Choose mature, fresh, non-deteriorating mulberries and clean them, soak them in salt water with a mass concentration of 7% for 20 minutes, remove them, and rinse them with sterile water. After rinsing, dry the surface water of the mulberries and set aside;

[0040] Screening and processing of black medlar: Select mature, fresh, and non-deteriorating black medlar to clean, soak in 7% by mass salt water for 20 minutes, rinse with sterile water a...

Embodiment 2

[0053] A formula of mulberry wine combined with solid-liquid fermentation is made of raw materials with the following weight components: 8 parts of mulberries, 3 parts of black wolfberry, and 8 parts of black glutinous rice.

[0054] A method for making mulberry wine combined with solid-liquid fermentation, including: material selection processing, juice separation, solid-state fermentation, retort distillation, blending and mixing, and liquid fermentation;

[0055] (1) Material selection processing:

[0056] Screening and processing of mulberries: Choose mature, fresh, non-deteriorating mulberries and clean them, soak them in salt water with a mass concentration of 7% for 20 minutes, remove them, and rinse them with sterile water. After rinsing, dry the surface water of the mulberries and set aside;

[0057] Screening and processing of black medlar: Select mature, fresh, and non-deteriorating black medlar to clean, soak in 7% by mass salt water for 20 minutes, rinse with sterile water...

Embodiment 3

[0070] A formula of mulberry wine combined with solid-liquid fermentation is made of raw materials with the following weight components: 8 parts of mulberries, 1 part of black wolfberry, and 12 parts of black glutinous rice.

[0071] A method for making mulberry wine combined with solid-liquid fermentation, including: material selection processing, juice separation, solid-state fermentation, retort distillation, blending and mixing, and liquid fermentation;

[0072] (1) Material selection processing:

[0073] Screening and processing of mulberries: Choose mature, fresh, non-deteriorating mulberries and clean them, soak them in salt water with a mass concentration of 7% for 20 minutes, remove them, and rinse them with sterile water. After rinsing, dry the surface water of the mulberries and set aside;

[0074] Screening and processing of black medlar: Select mature, fresh, and non-deteriorating black medlar to clean, soak in 7% by mass salt water for 20 minutes, rinse with sterile water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com