Preparation method of nanometer copper sulfide

A copper sulfide and nanotechnology, applied in the field of nanomaterials, can solve problems such as environmental hazards, high reaction temperature, and long reaction time, and achieve the effects of low equipment requirements, good dispersion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of nano-copper sulfide, the specific steps are:

[0033] (1) At room temperature (25°C), add 50 mg of sodium tripolyphosphate, 40 mg of folic acid and 0.120 g of sodium sulfide nonahydrate into 50 g of deionized water, stir evenly until completely dissolved into light yellow transparent solution A.

[0034] (2) At room temperature (25° C.), add 0.085 g of copper chloride dihydrate into 10 g of deionized water and stir to dissolve evenly to obtain solution B.

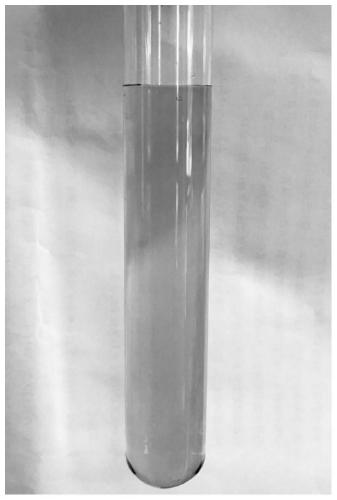

[0035] (3) At room temperature (25°C), place solution A on a magnetic stirrer with a rotating speed of 200rpm, and add solution B dropwise to solution A under stirring conditions, and the solution quickly becomes a dark brown copper sulfide suspension, Continue to stir for half an hour after the dropwise addition to obtain nano-copper sulfide suspension. The particle size of the copper sulfide nanoparticles contained in the nano copper sulfide suspension is 5-10nm.

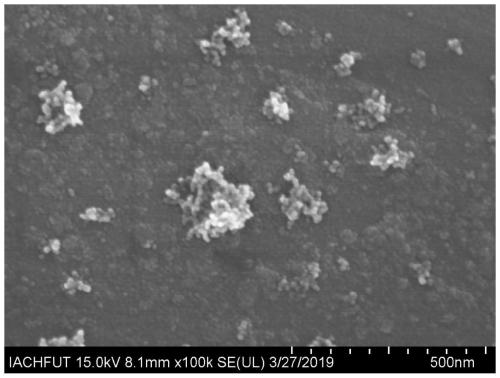

[0036] figure 1 It is t...

Embodiment 2

[0040] A preparation method of nano-copper sulfide, the specific steps are:

[0041] (1) At room temperature (25°C), add 50 mg of sodium tripolyphosphate, 40 mg of folic acid and 0.120 g of sodium sulfide nonahydrate into 50 g of deionized water and stir until completely dissolved into a light yellow transparent solution A.

[0042] (2) At room temperature (25° C.), add 0.125 g of copper sulfate pentahydrate into 10 g of deionized water and stir to dissolve evenly to obtain solution B.

[0043] (3) At room temperature (25°C), place solution A on a magnetic stirrer with a rotating speed of 200rpm, and add solution B dropwise to solution A under stirring conditions, and the solution quickly becomes a dark brown copper sulfide suspension, After the dropwise addition, continue to stir for half an hour to obtain a nano-copper sulfide suspension. The particle size of the copper sulfide nanoparticles contained in the nano copper sulfide suspension is 5-10nm.

Embodiment 3

[0045] A preparation method of nano-copper sulfide, the specific steps are:

[0046] (1) At room temperature (25°C), add 50 mg of sodium tripolyphosphate, 40 mg of folic acid and 0.120 g of sodium sulfide nonahydrate into 50 g of deionized water and stir until completely dissolved into a light yellow transparent solution A.

[0047] (2) At room temperature (25° C.), 0.094 g of copper nitrate was added to 10 g of deionized water, stirred and dissolved evenly to obtain solution B.

[0048](3) At room temperature (25°C), place solution A on a magnetic stirrer with a rotating speed of 200rpm, and add solution B dropwise to solution A under stirring conditions, and the solution quickly becomes a dark brown copper sulfide suspension, After the dropwise addition, continue to stir for half an hour to obtain a nano-copper sulfide suspension. The particle size of the copper sulfide nanoparticles contained in the nano copper sulfide suspension is 5-10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com