Method for removing pollutants in water by micro-electrolysis enhanced flotation

A technology of water pollutants and micro-electrolysis, applied in the direction of water pollutants, flotation water/sewage treatment, chemical instruments and methods, etc., can solve the problems of ineffective removal of organic matter and metal ions, and achieve high product added value and low cost Low, conducive to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

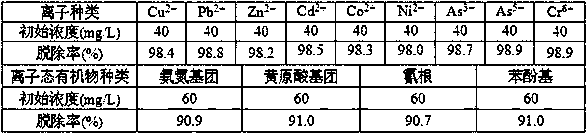

[0018] A method of micro-electrolysis enhanced flotation to remove water pollutants, Cu in wastewater 2+ , Pb 2+ , Zn 2+ 、Cd 2+ 、Co 2+ 、Ni 2+ 、As 3+ 、As 5+ 、Cr 6+ , the total concentration is 45mg / L, the ionic organic matter is ammonia nitrogen group, xanthate group, cyanide group, phenol group, the total content is 40mg / L, and the pH is 4.0.

[0019] The specific steps are as follows: the mass parts are composed of 72 parts of iron powder, 8 parts of manganese powder, 2 parts of carbon powder, 15 parts of bentonite, and 3 parts of ammonium bicarbonate, mix well, gradually add distilled water, carry out granulation, roast under nitrogen atmosphere, roast The temperature is 600°C, the roasting time is 50min, and the ferromanganese carbon material with an average particle size of 3mm and an ellipsoidal shape is filled into the flotation column; the filling method is tray type, the number of trays is 6, and the filling rate is 6%; Into the flotation column, water containi...

Embodiment 2

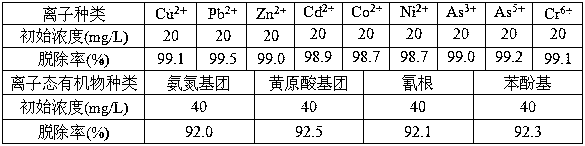

[0023] A method for micro-electrolysis enhanced flotation column removal of water pollutants, Cu in wastewater 2+ , Pb 2+ , Zn 2+ 、Cd 2+ 、Co 2+ 、Ni 2+ 、As 3+ 、As 5+ 、Cr 6+ , the total concentration is 180mg / L, the ionic organic matter is ammonia nitrogen group, xanthate group, cyanide group, phenol group, the total content is 160mg / L, and the pH is 6.0.

[0024] The specific steps are as follows: the mass parts are composed of 70 parts of iron powder, 9 parts of manganese powder, 2 parts of carbon powder, 15 parts of bentonite, and 4 parts of ammonium bicarbonate, mix well, gradually add distilled water, carry out granulation, roast under nitrogen atmosphere, roast The temperature is 750°C, the roasting time is 70min, and the iron-manganese-carbon material with an average particle size of 3.5mm and an ellipsoidal shape is filled into the flotation column; the filling method is tray type, the number of trays is 7, and the filling rate is 7%. ; Into the flotation column,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com