Quick formaldehyde testing method for textiles

A test method and technology for textiles, which are applied in chemical analysis by titration, analysis by chemical reaction of materials, and material analysis by observing the effect on chemical indicators, which can solve the problem of long inspection time and poor extraction effect. , the problem of high detection cost, to achieve the effect of convenient operation, fast detection, convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

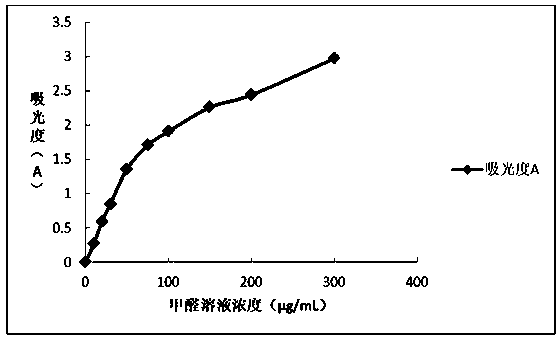

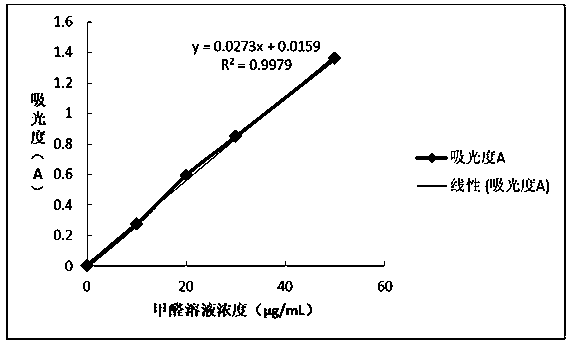

[0030] Using the characteristic color development principle of formaldehyde and phenylhydrazine hydrochloride, the ratio of different raw materials and the screening effect, to develop a rapid detection device for formaldehyde, and then from the selection of color reagent for formaldehyde testing, the choice of acidic environment, the choice of extraction effect, temperature conditions And the choice of sampling volume and other factors to optimize the reaction conditions, to achieve the simplest steps, the most obvious color effect. Finally, a formaldehyde rapid detection device or method suitable for formaldehyde detection in textiles and formaldehyde detection in enterprises and the public has been developed.

[0031] 1. Preparation

[0032] (1) Reagent

[0033] Hydrochloric acid (AR analytical grade)

[0034]Formaldehyde solution (AR analytically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com