Carbon circulating system and method based on ammonia-process decarburization and electrocatalytic reduction utilization

A technology of circulation system and catalytic system, which is applied in the field of carbon cycle, green energy application and decarbonization, can solve the problems of economic limitation and large electric energy, and achieve the effect of improving capture efficiency and solving overcapacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

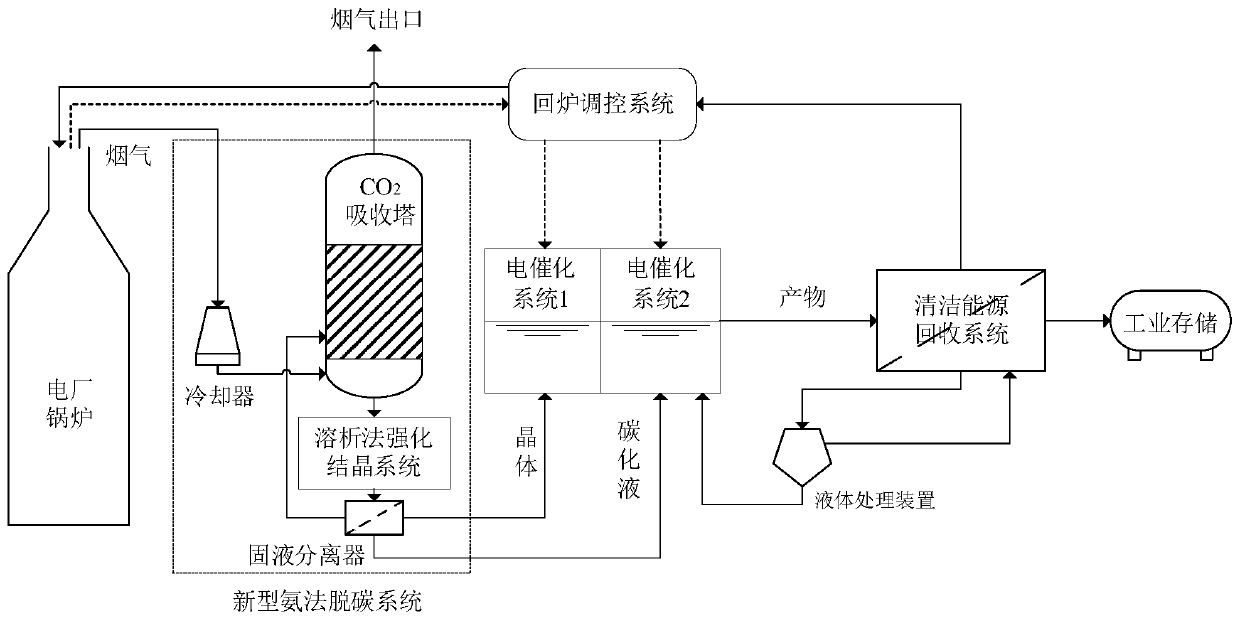

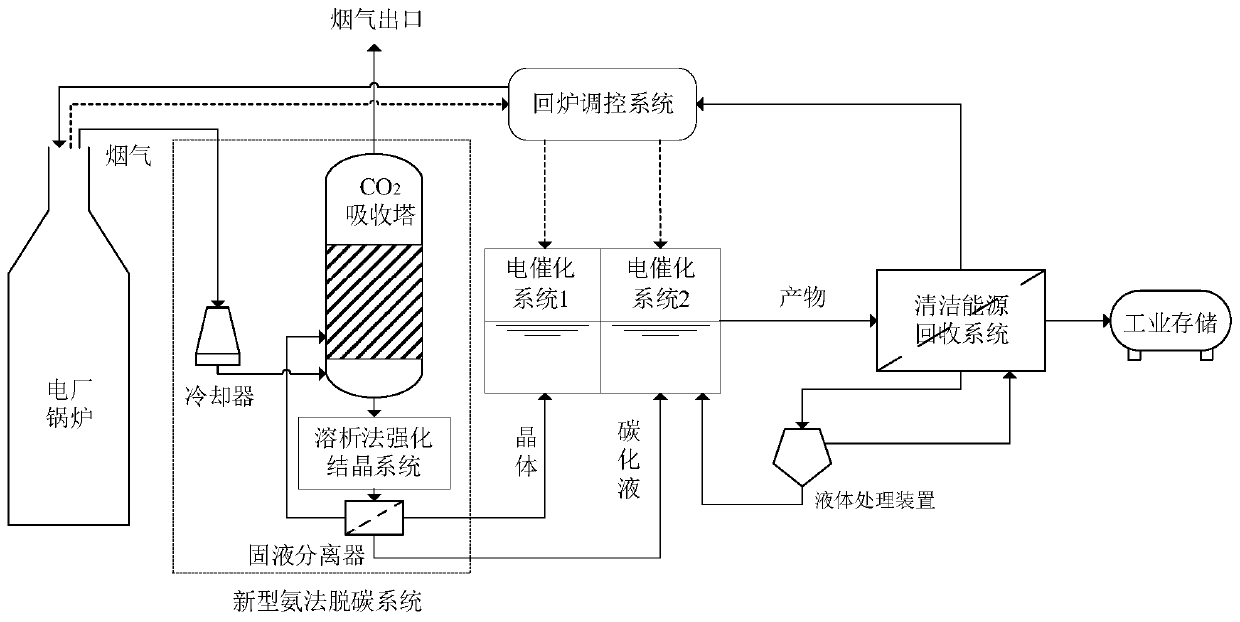

[0026] A carbon circulation system based on ammonia decarburization and electrocatalytic reduction utilization according to the present invention includes: ammonia decarburization system, electrocatalytic reduction system, clean energy recovery system and furnace return control system;

[0027] The new ammonia decarbonization system includes flue gas cooling device, CO 2Absorption tower, elution method enhanced crystallization system, and solid-liquid separation device; boiler flue gas enters the CO after being cooled by the cooler 2 Absorption tower, CO 2 Absorber absorbs CO using novel ammonia decarbonization method 2 , and pass the solution into the elution enhanced crystallization system for CO 2 The enhanced crystallization of the absorption and the recycling of the absorbent; the product crystals and carbonized liquid are separated by a solid-liquid separation device and sent to the electrocatalytic system 1 and electrocatalytic system 2 respectively. The remaining fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com