Deep purification device and method of electrolytic aluminum exhaust gas

A technology for deep purification of flue gas and electrolysis of aluminum, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as difficulty in implementation, high investment and operation costs, secondary pollution, etc., and achieve improved operation stability and investment Low operating cost and avoid freezing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the relationship between the components in a certain posture (as shown in the accompanying drawings). Relative positional relationship, movement conditions, etc., if the specific posture changes, the directional indication will also change accordingly.

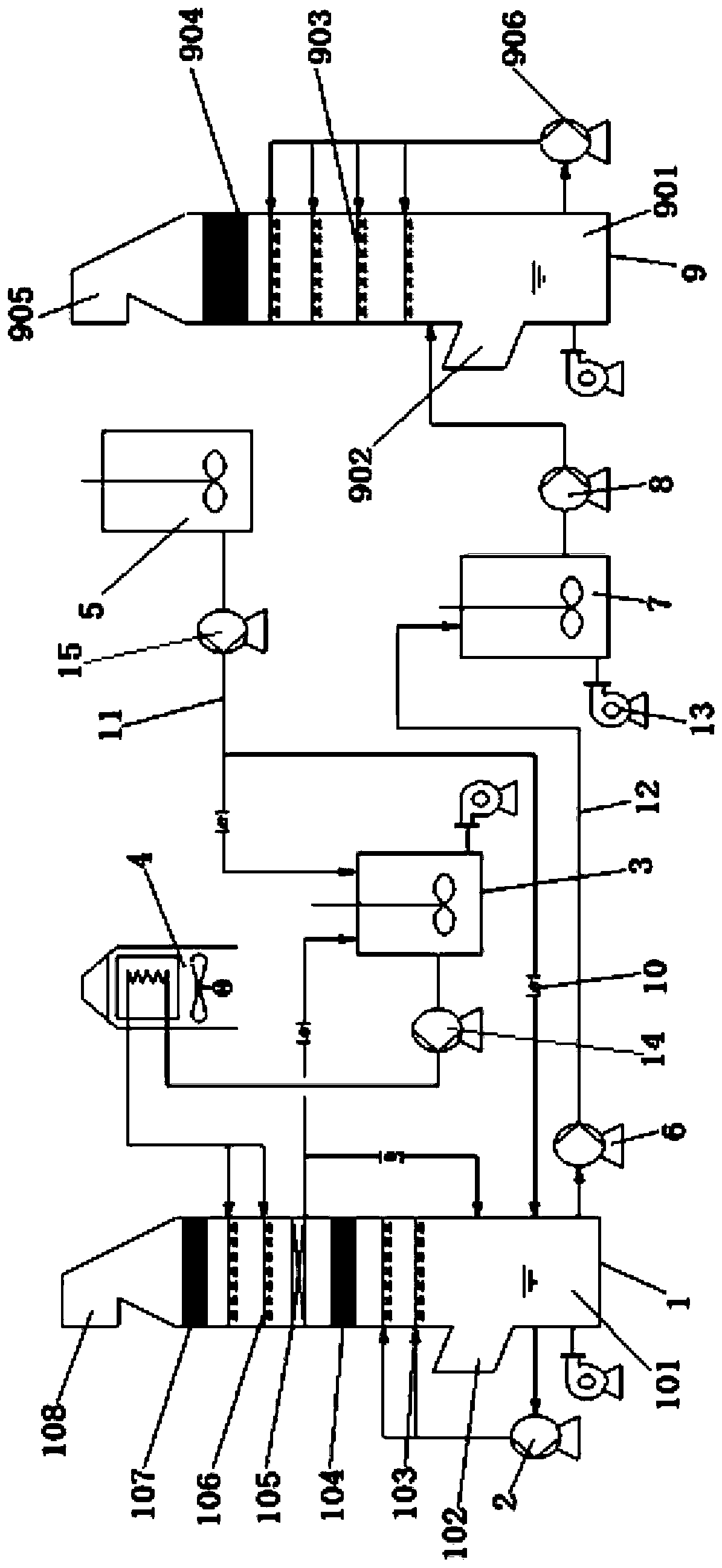

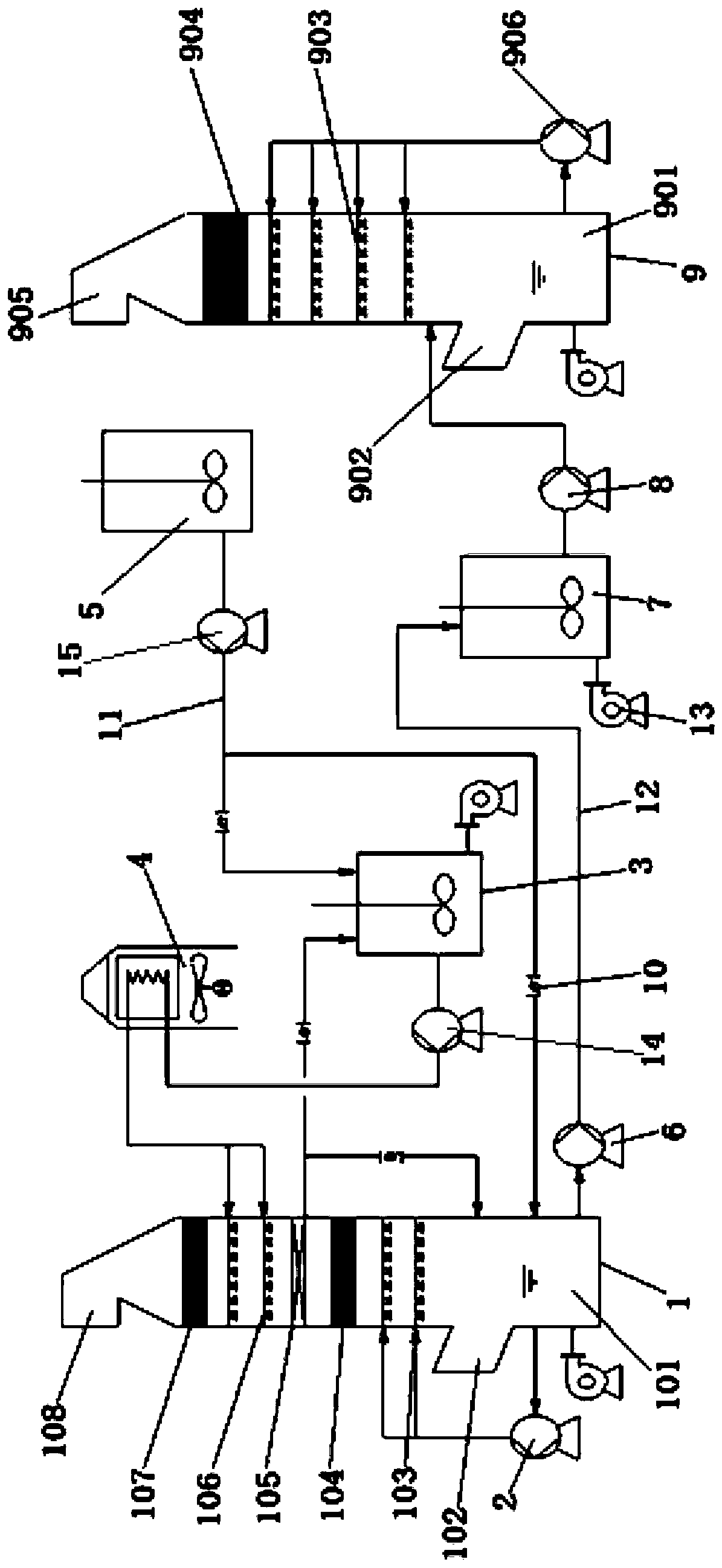

[0028] like figure 1As shown, the present invention provides a deep purification device for electrolytic aluminum flue gas, including an electrolytic aluminum purification tower 1, a purification tower circulation pump 2, a condensation circulation pump 14, a limestone slurry pump 15, a limestone slurry circulation box 3, and a circulation cooling tower 4 , Limestone slurry storage tank 5 and gypsum slurry processing system, the electrolytic aluminum purification tower 1 is respectively provided with a gypsum slurry circulation area 101, an inlet flue 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com