Method for preparing block compound Fenton-like catalyst material, obtained material and application

A composite and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve secondary pollution, easy to generate sludge, and complex composite steps and other problems, to achieve the effect of convenient use and recycling, and reduce the steps of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Take 12.4 moles of water and 30.6 moles of absolute ethanol and mix and stir for 10 minutes, then add 1.68 moles of n-butylamine, stir for 30 minutes, then add 1 mole of tetraethyl orthosilicate, stir for 4 minutes and then let stand for 6 minutes. After the gel is aged for 1 hour, a wet gel is obtained; the wet gel is put into an oven at 80 o C drying for 4 hours to obtain SiO 2 dry gel.

[0043] (2) According to Fe / SiO 2 The molar ratio is 0.1, respectively weigh the corresponding iron oxide and SiO 2 The dry gel is put into a ball mill jar, and ball milled and compounded on a ball mill to obtain a compound powder.

[0044] (3) The composite powder is molded to obtain a green body. The green body material obtained was heated at a rate of 5 in a nitrogen atmosphere furnace. o C / min rises to 550 o C was calcined for 6 hours to obtain a bulk composite Fenton-like catalyst material.

[0045] (4) Add 0.5g of the prepared bulk composite Fenton-like catalyst mater...

Embodiment 2

[0048] (1) Same as embodiment 1.

[0049] (2) According to Fe / SiO 2 is 0.1, and the C / Fe molar ratio is 2, respectively weigh the corresponding SiO 2 The xerogel, iron oxide and carbon black powder are mixed, put into a ball mill tank, and ball milled on a ball mill to obtain a composite powder.

[0050] (3) The composite powder is molded to obtain a green body of the block composite material. The green body material obtained was heated at a rate of 5 in a nitrogen atmosphere furnace. o C / min rises to 550 o C was calcined for 6 hours to obtain a bulk composite Fenton-like catalyst material.

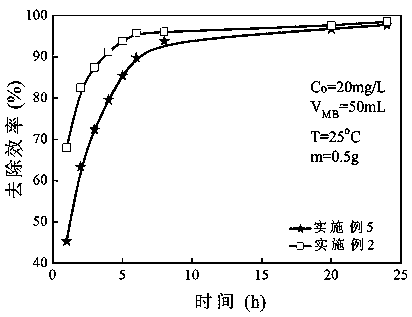

[0051] (4) Add 0.5g of the prepared bulk composite Fenton-like catalyst material to 50mL of 20mg / L methylene blue solution, add 1mL of 30% hydrogen peroxide solution, and place it in a water bath constant temperature oscillator for adsorption and degradation for 1~ 24 hours.

[0052] Through nitrogen adsorption and desorption analysis, the specific surface area of the composite ma...

Embodiment 3

[0054] (1) ~ (2) with embodiment 2.

[0055] (3) The composite powder is molded to obtain a green body of the block composite material. The obtained green body material was heated in an air atmosphere muffle furnace at a heating rate of 5 o C / min rises to 550 o C was calcined for 6 hours to obtain a bulk composite Fenton-like catalyst material.

[0056] (4) Add 0.5g of the prepared bulk composite Fenton-like catalyst material to 50mL of 20mg / L methylene blue solution, add 1mL of 30% hydrogen peroxide solution, and place it in a water bath constant temperature oscillator for adsorption and degradation for 1~ 24 hours.

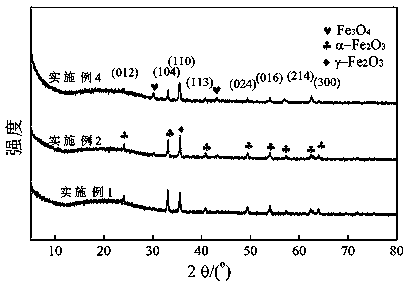

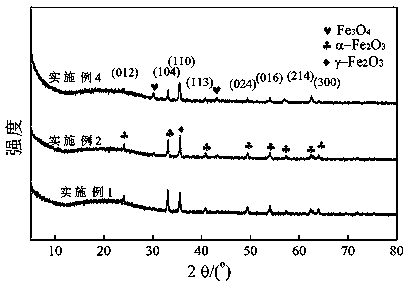

[0057] Through nitrogen adsorption and desorption analysis, the specific surface area of the composite material is 599m 2 / g, the pore diameter is 12.1nm, and the pore volume is 0.785mL / g; the divalent and trivalent iron in the material account for 13.8% and 86.2% respectively; the material contains α-Fe 2 o 3 , γ-Fe 2 o 3 Crystal phase and Fe 3 o 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com