Transition metal doped g-C3N4 powder and preparation method thereof

A transition metal, g-c3n4 technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as large environmental pollution, achieve small environmental pollution, high specific surface area, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

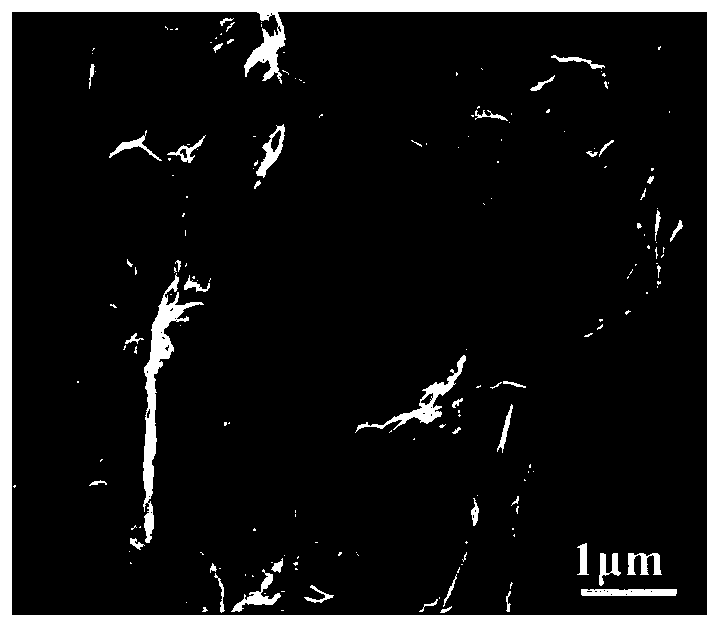

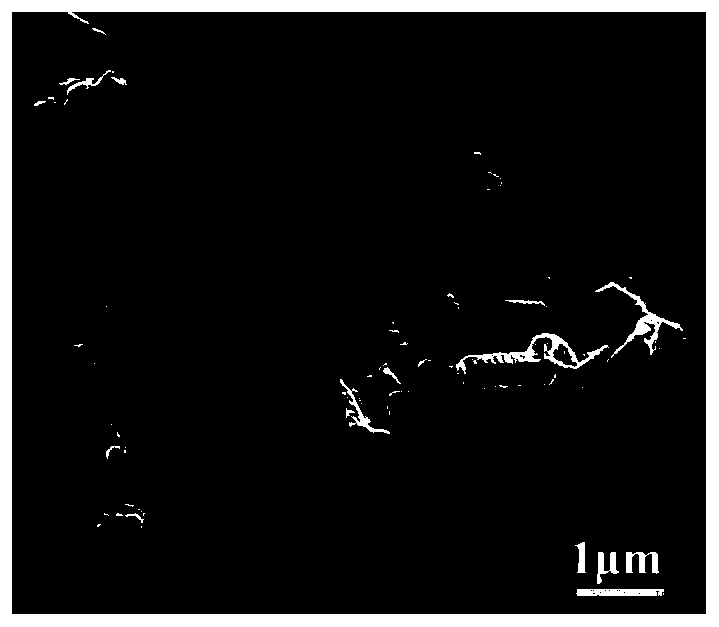

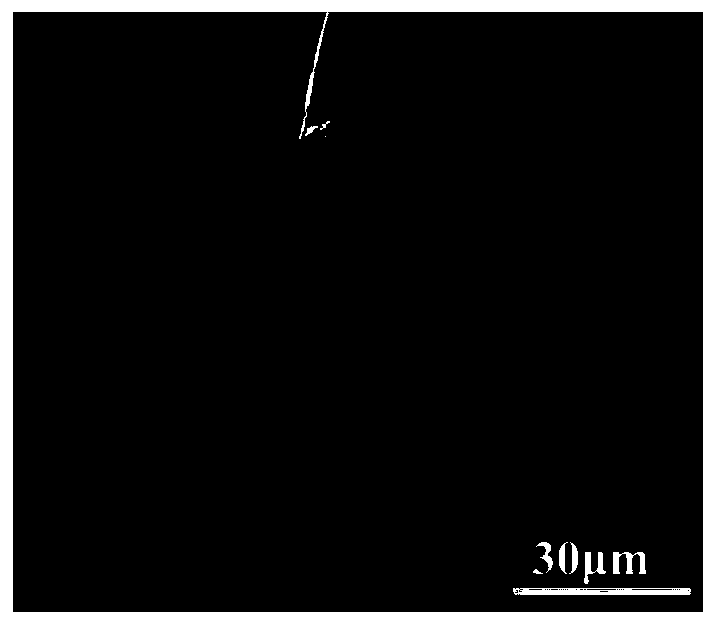

Image

Examples

Embodiment 1

[0026] A transition metal doped g-C 3 N 4 Powder and its preparation method. The specific steps of the preparation method described in this embodiment are:

[0027] According to the nitrogen-containing compound: the mass ratio of the transition metal inorganic salt is 1:0.01~0.018, the nitrogen-containing compound and the transition metal inorganic salt are mixed to obtain a mixture; then the solid-liquid ratio is 16.8~17.8g / L, Add the mixture into organic solvent I, stir for 1-3 hours, and hydrothermally treat it at 150-180°C for 60-80 hours; then wash it with organic solvent II for 3-5 times, filter it with suction, and dry it at 60-80°C for 8 ~10h, the transition metal doped g-C 3 N 4 complex precursors.

[0028] Step 2. Transition metal doping g-C 3 N 4 Powder preparation

[0029] Under protective atmosphere conditions, the transition metal is doped with g-C at a rate of 5-8°C / min 3 N 4 The complex precursor is heated to 450-480°C and kept for 2-4 hours to prepar...

Embodiment 2

[0036] A transition metal doped g-C 3 N 4 Powder and its preparation method. The specific steps of the preparation method described in this embodiment are:

[0037] According to the nitrogen-containing compound: the mass ratio of the transition metal inorganic salt is 1:0.018~0.026, the nitrogen-containing compound and the transition metal inorganic salt are mixed to obtain a mixture; then the solid-liquid ratio is 17.6~18.6g / L, Add the mixture into organic solvent I, stir for 1-3 hours, and hydrothermally treat it at 150-180°C for 60-80 hours; then wash it with organic solvent II for 3-5 times, filter it with suction, and dry it at 60-80°C for 8 ~10h, the transition metal doped g-C 3 N 4 complex precursors.

[0038] Step 2. Transition metal doping g-C 3 N 4 Powder preparation

[0039] Under protective atmosphere conditions, the transition metal is doped with g-C at a rate of 5-8°C / min 3 N 4 The complex precursor is heated to 480-510°C and kept for 2-4 hours to prepa...

Embodiment 3

[0046] A transition metal doped g-C 3 N 4 Powder and its preparation method. The specific steps of the preparation method described in this embodiment are:

[0047] According to the nitrogen-containing compound: the transition metal inorganic salt mass ratio is 1: 0.026~0.034, the nitrogen-containing compound and the transition metal inorganic salt are mixed to obtain a mixture; then the solid-liquid ratio is 18.4~19.4g / L, Add the mixture into organic solvent I, stir for 1-3 hours, and hydrothermally treat it at 150-180°C for 60-80 hours; then wash it with organic solvent II for 3-5 times, filter it with suction, and dry it at 60-80°C for 8 ~10h, the transition metal doped g-C 3 N 4 complex precursors.

[0048] Step 2. Transition metal doping g-C 3 N 4 Powder preparation

[0049] Under protective atmosphere conditions, the transition metal is doped with g-C at a rate of 5-8°C / min 3 N 4 The complex precursor is heated to 510-540°C and kept for 2-4 hours to prepare tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com