Preparation method of precious metal-loaded porous organic framework atomic-scale catalyst capable of catalytic degradation of VOCs at normal temperature

An organic framework, catalytic degradation technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as hidden dangers, safety of VOCs, high energy consumption, etc. Achieve enhanced safety, easy regulation of active sites, and high catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

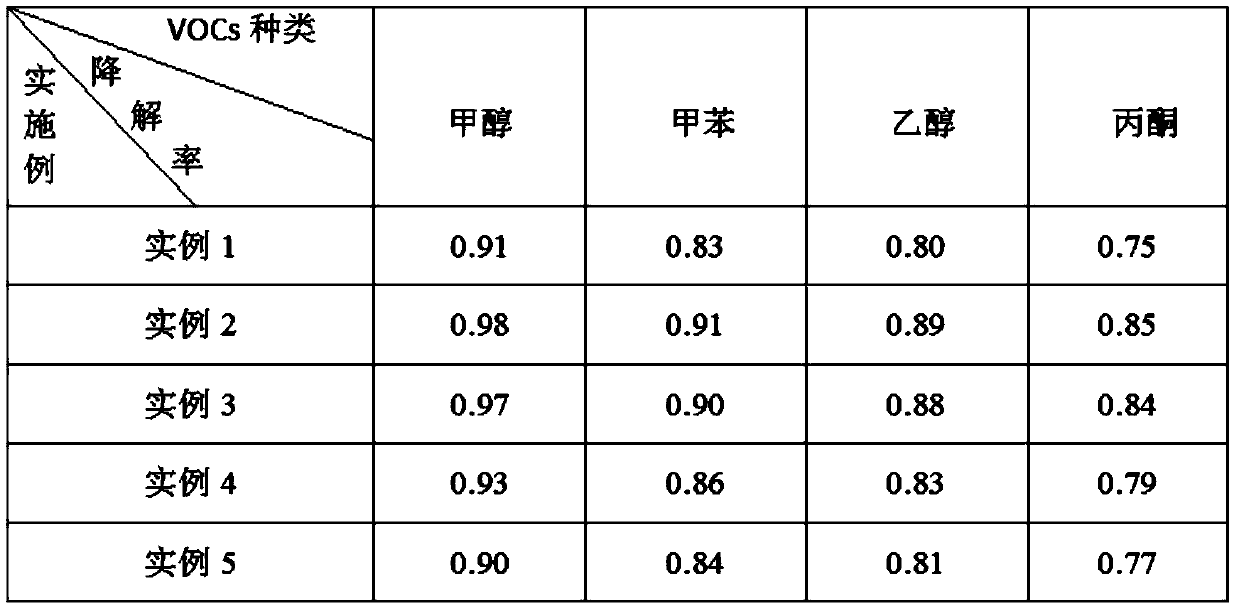

Examples

preparation example Construction

[0022] The preparation method of the noble metal-loaded porous organic framework atomic-level catalyst that can be used for catalytic degradation of VOCs at room temperature of the present invention comprises the following steps:

[0023] (a) Prepare the carrier:

[0024] (1) Add triethylamine into the dichloromethane solution, stir evenly to obtain the first solution, and the volume ratio of triethylamine to dichloromethane is 1:10.

[0025] (2) Add 2,6-diaminopyridine and 1,3,5-benzenetricarbonyl chloride in a molar ratio of 3:1 to the first solution and stir to obtain a second solution; the 2, The volume ratio of the total volume of 6-diaminopyridine and 1,3,5-benzenetricarboxylic acid chloride to the first solution is 1:2.

[0026] (3) Put the second solution in an oil bath and react at 20-90° C. for 2-8 hours to generate a porous organic framework containing pyridine-amide functional groups.

[0027] Preferably, the temperature of the oil bath is 40-60°C, and the reacti...

Embodiment 1

[0038] (a) Preparation of carrier

[0039] (1) Add triethylamine into the dichloromethane solution, stir evenly to obtain the first solution, the volume ratio of triethylamine and dichloromethane is 1:10.

[0040] (2) Add 2,6-diaminopyridine and 1,3,5-benzenetricarboxylic acid chloride with a molar ratio of 3:1 into the first solution and stir to obtain a second solution; 2,6-diaminopyridine The volume ratio of the total volume of aminopyridine and 1,3,5-benzenetricarboxylic acid chloride to the first solution is 1:2.

[0041] (3) The second solution was placed in an oil bath and reacted at 20° C. for 8 hours to generate a porous organic framework containing pyridine-amide functional groups.

[0042] (b) Impregnated loaded Pt metal

[0043] (1) The porous organic framework is completely impregnated into 0.05mol / L H 2 PtCl 6 The solution was subjected to ultrasonic treatment for 1 h, and then stood at 10 °C for 6 h to obtain a porous organic framework loaded with Pt metal. ...

Embodiment 2

[0050] (a) Prepare the carrier:

[0051] (1) Add triethylamine into the dichloromethane solution, stir evenly to obtain the first solution, the volume ratio of triethylamine and dichloromethane is 1:10.

[0052](2) Add 2,6-diaminopyridine and 1,3,5-benzenetricarboxylic acid chloride with a molar ratio of 3:1 into the first solution and stir to obtain a second solution; 2,6-diaminopyridine The volume ratio of the total volume of aminopyridine and 1,3,5-benzenetricarboxylic acid chloride to the first solution is 1:2.

[0053] (3) The second solution was placed in an oil bath and reacted at 40° C. for 6 hours to generate a porous organic framework containing pyridine-amide functional groups.

[0054] (b) Impregnated loaded Pt metal

[0055] (1) The porous organic framework is completely impregnated into 0.2mol / L H 2 PtCl 6 The solution was subjected to ultrasonic treatment for 1.5 h, and then stood at 20° C. for 8 h to obtain a porous organic framework loaded with Pt metal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com