Harmless treatment method of industrial waste salt containing organic matter

A technology of harmless treatment and industrial waste salt, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as poor adsorption of organic matter, limited industrialization and application, loss of adsorption effect, etc. To solve the problem of treatment and disposal, facilitate crushing and recycling, and facilitate oxidation and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The waste salt residue precipitated from a three-effect evaporator of a fine chemical company is treated by the process of the present invention. The waste salt is in the form of light yellow powder block. After testing, the waste salt contains 86.5% sodium chloride, 4.6% moisture, 1.2g organic matter and For other impurities, the waste salt is currently entrusted to the factory as hazardous waste for treatment and disposal.

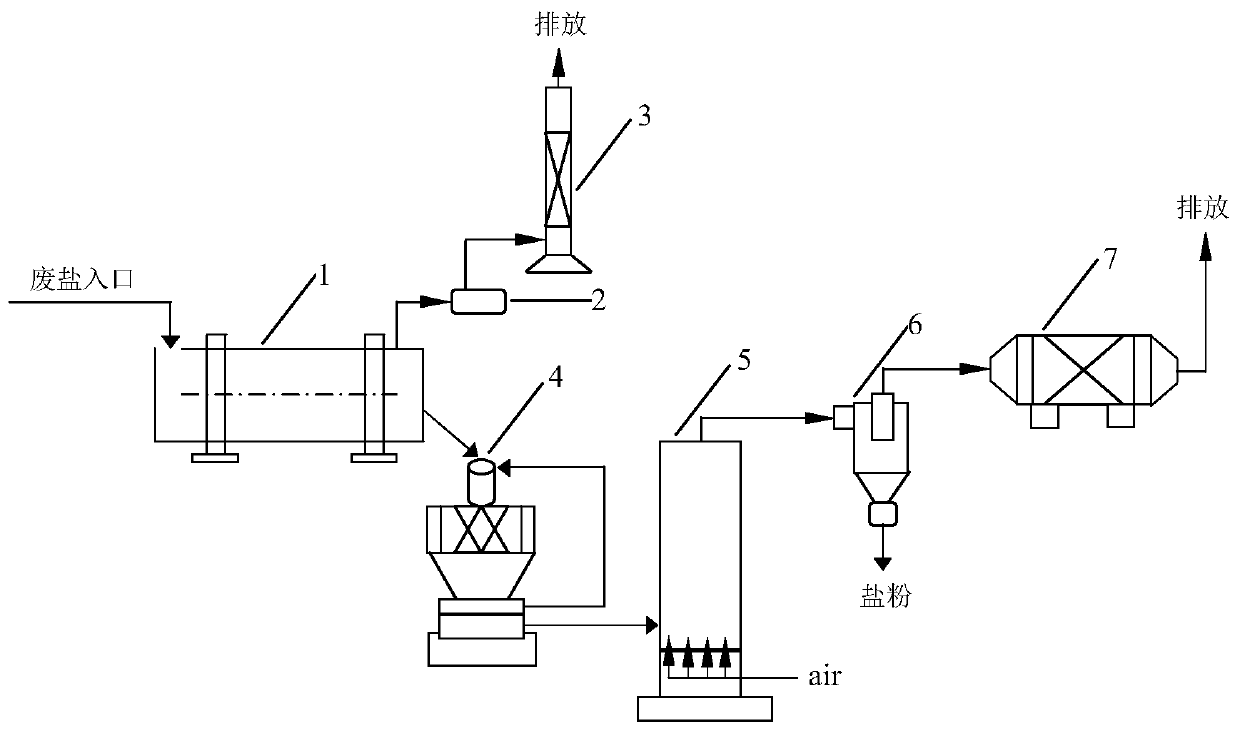

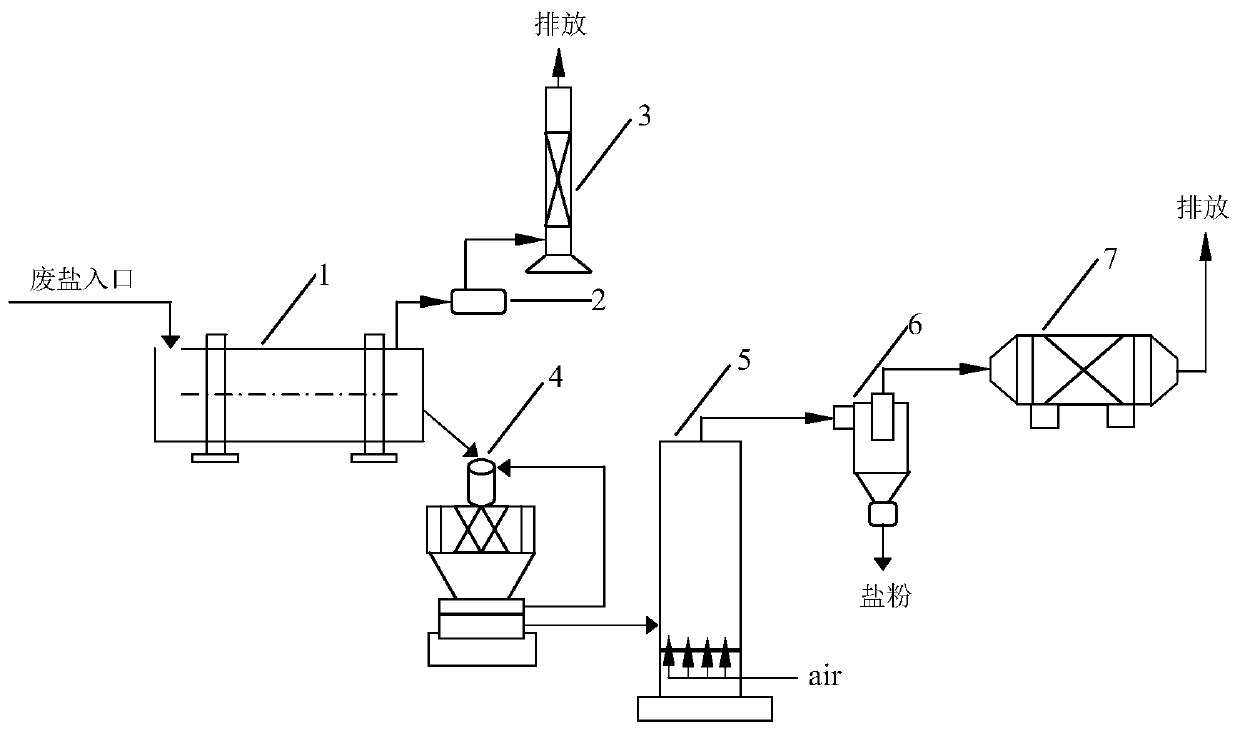

[0034] Place the waste salt in the dryer 1 and dry it at 130°C, then send the dried waste salt to the crushing and classifying machine 4 for crushing and sieving, adjust the sieve to a 100-mesh sieve, and put the crushed The final waste salt particles are sieved, and the fine particles obtained after sieving are sent into the pyrolysis furnace 5, and pyrolyzed under the condition of 350 ° C furnace temperature and staying in the furnace for 2 minutes, and finally the salt particles are separated by the cyclone separator 6 Separated from the organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com