High-glow wire flame-retardant reinforced PBT plastic for printing white characters through laser and preparation method of PBT plastic

A high-glow wire and laser technology, which is applied in the field of polymer materials, achieves the effects of taking into account flame retardancy and mechanical properties, increasing the temperature of the glow wire, and good laser effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

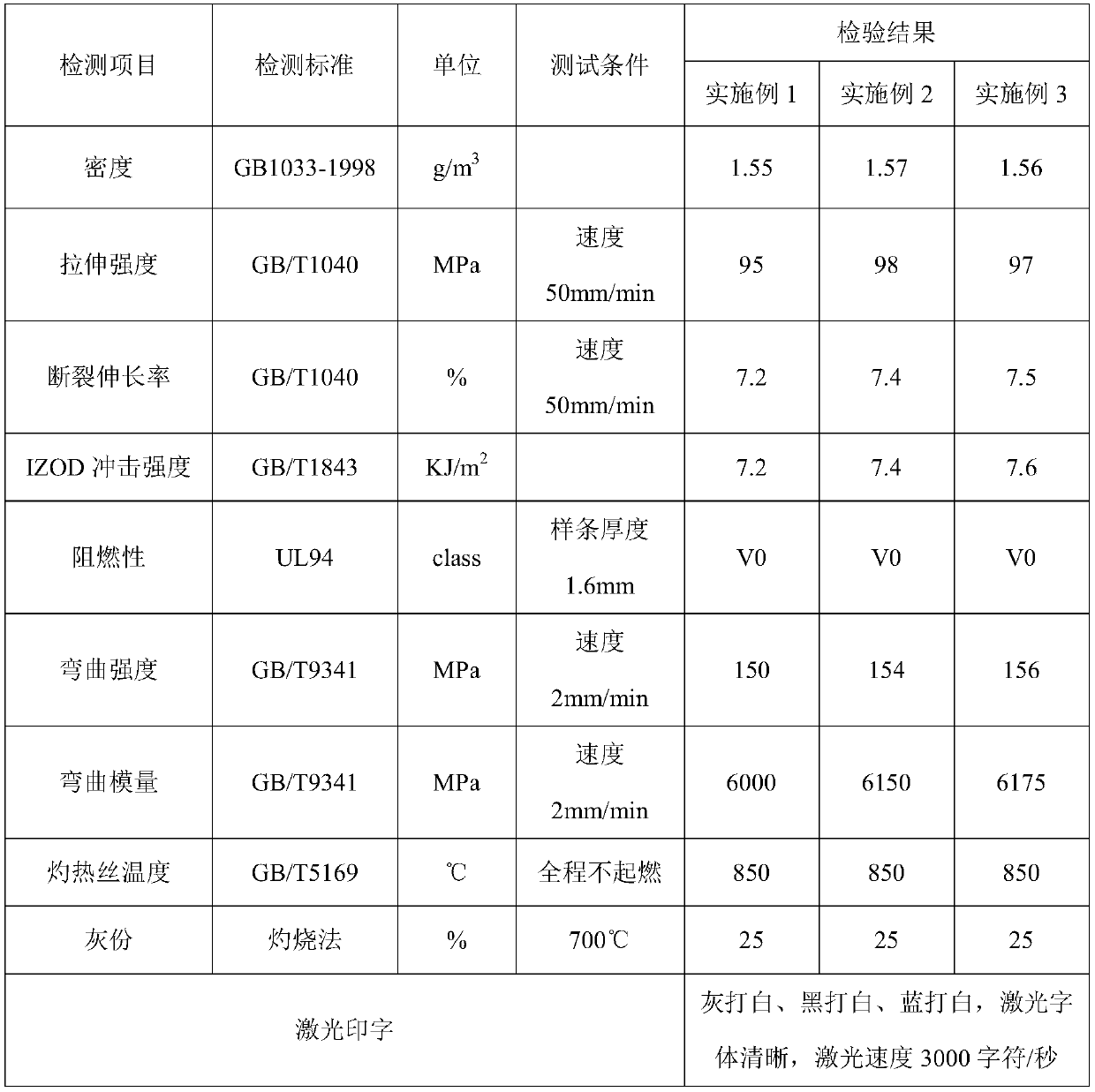

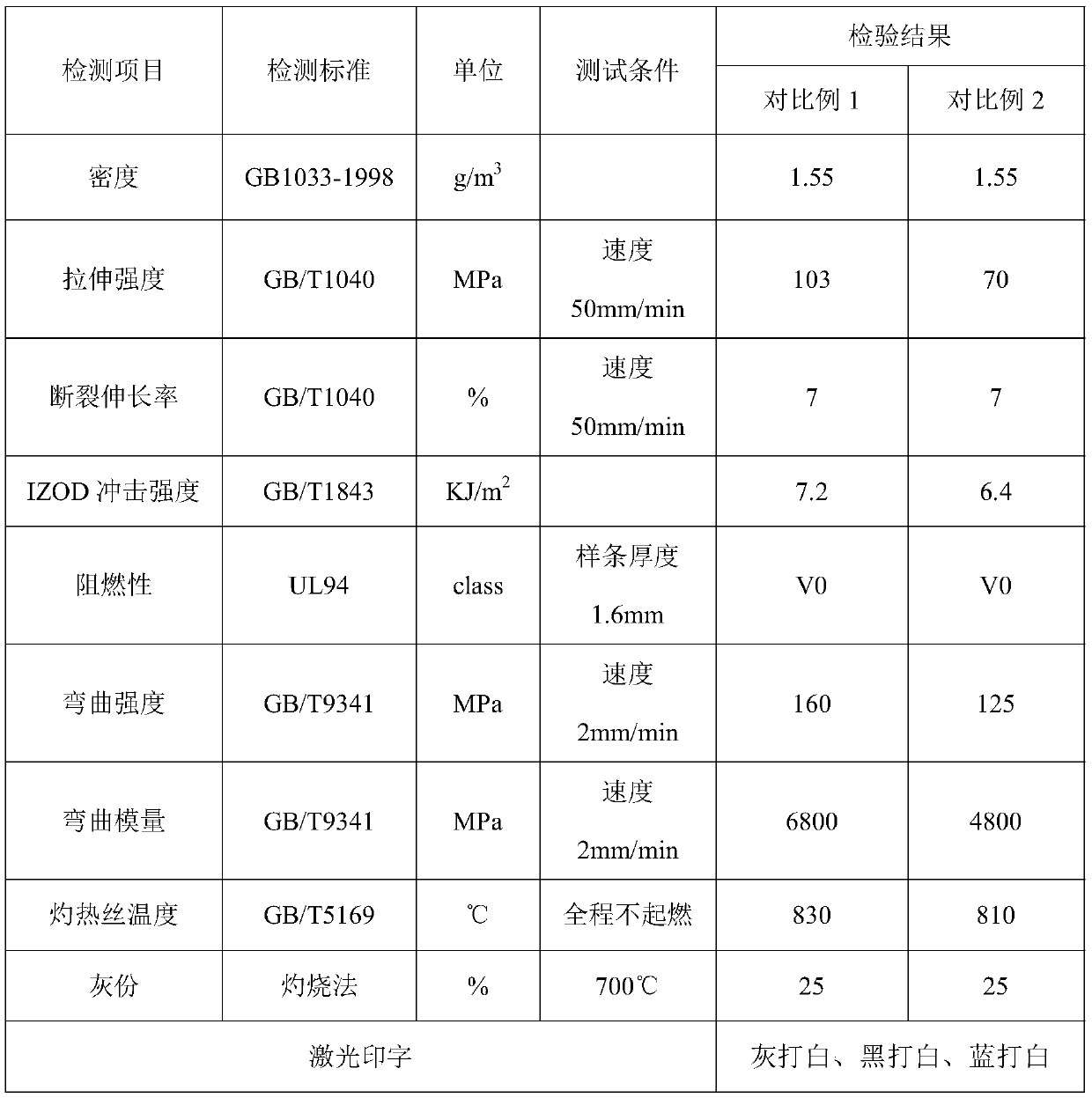

Examples

Embodiment 1

[0034] A high glow wire flame-retardant reinforced laser-printed white PBT plastic, which includes the following components in terms of mass percentage:

[0035] PBT 40%;

[0036] PET 5%;

[0037] MCA 10%;

[0038] Brominated epoxy resin 11%;

[0039] Sodium antimonate 1%;

[0040] TPP 3%;

[0041] EMA-g-GMA 2%;

[0042] Metal (Group B) oxide 2%;

[0043] Antioxidant 0.5%;

[0044] Lubricant 0.5%;

[0045] Glass fiber 25%.

[0046] The intrinsic viscosity of the PBT used in this example is 0.8 to 0.9 dl / g. MCA is MCA that has been surface pretreated with a silane coupling agent. The brominated epoxy resin used has a molecular weight of 20,000. The metal (group B oxide) used is a compound metal oxide composed of copper oxide and zinc oxide with a mass ratio of 1:1. The antioxidant used is a compound antioxidant composed of antioxidant 1010 and antioxidant 168 with a mass ratio of 3:2. The lubricant used was silicone powder.

[0047] In this example, the preparation method of high glow wire ...

Embodiment 2

[0053] A high glow wire flame-retardant reinforced laser-printed white PBT plastic, which includes the following components in terms of mass percentage:

[0054] PBT 40%;

[0055] PET 5%;

[0056] MCA 9%;

[0057] Brominated epoxy resin 12%;

[0058] Sodium antimonate 1%;

[0059] TPP 3%;

[0060] EMA-g-GMA 2%;

[0061] Metal (Group B) oxide 2%;

[0062] Antioxidant 0.5%;

[0063] Lubricant 0.5%;

[0064] Glass fiber 25%.

[0065] The metal (group B oxide) used in this example is a compound metal oxide composed of copper oxide and titanium oxide at a mass ratio of 1:1, and the types of other raw materials are the same as in Example 1.

[0066] The preparation method of the high glow wire flame-retardant reinforced laser-printed white PBT plastic in this example is the same as that of Example 1.

Embodiment 3

[0068] A high glow wire flame-retardant reinforced laser-printed white PBT plastic, which includes the following components in terms of mass percentage:

[0069] PBT 40.5%;

[0070] PET 5%;

[0071] MCA 9%;

[0072] Brominated epoxy resin 12%;

[0073] Sodium antimonate 1%;

[0074] TPP 3%;

[0075] EMA-g-GMA 2%;

[0076] Metal (Group B) oxide 1.5%;

[0077] Antioxidant 0.5%;

[0078] Lubricant 0.5%;

[0079] Glass fiber 25%.

[0080] The metal (group B oxide) used in this example is a compound metal oxide composed of chromium oxide and manganese oxide at a mass ratio of 1:1, and the types of other raw materials are the same as in Example 1.

[0081] The preparation method of the high glow wire flame-retardant reinforced laser-printed white PBT plastic in this example is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com