Preparation method of nanocellulose bio-printing gel ink

A nanocellulose and bioprinting technology, applied in inks, home appliances, applications, etc., can solve the problems of no cell adhesion, mismatch of natural tissue strength, calcium ion loss, etc., and achieve the solution of insufficient mechanical properties and excellent biophase The effect of capacitive, broad applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

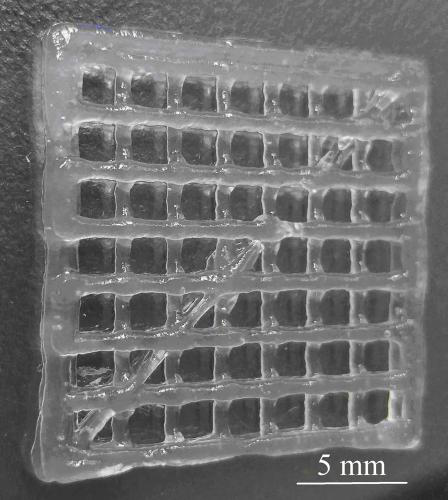

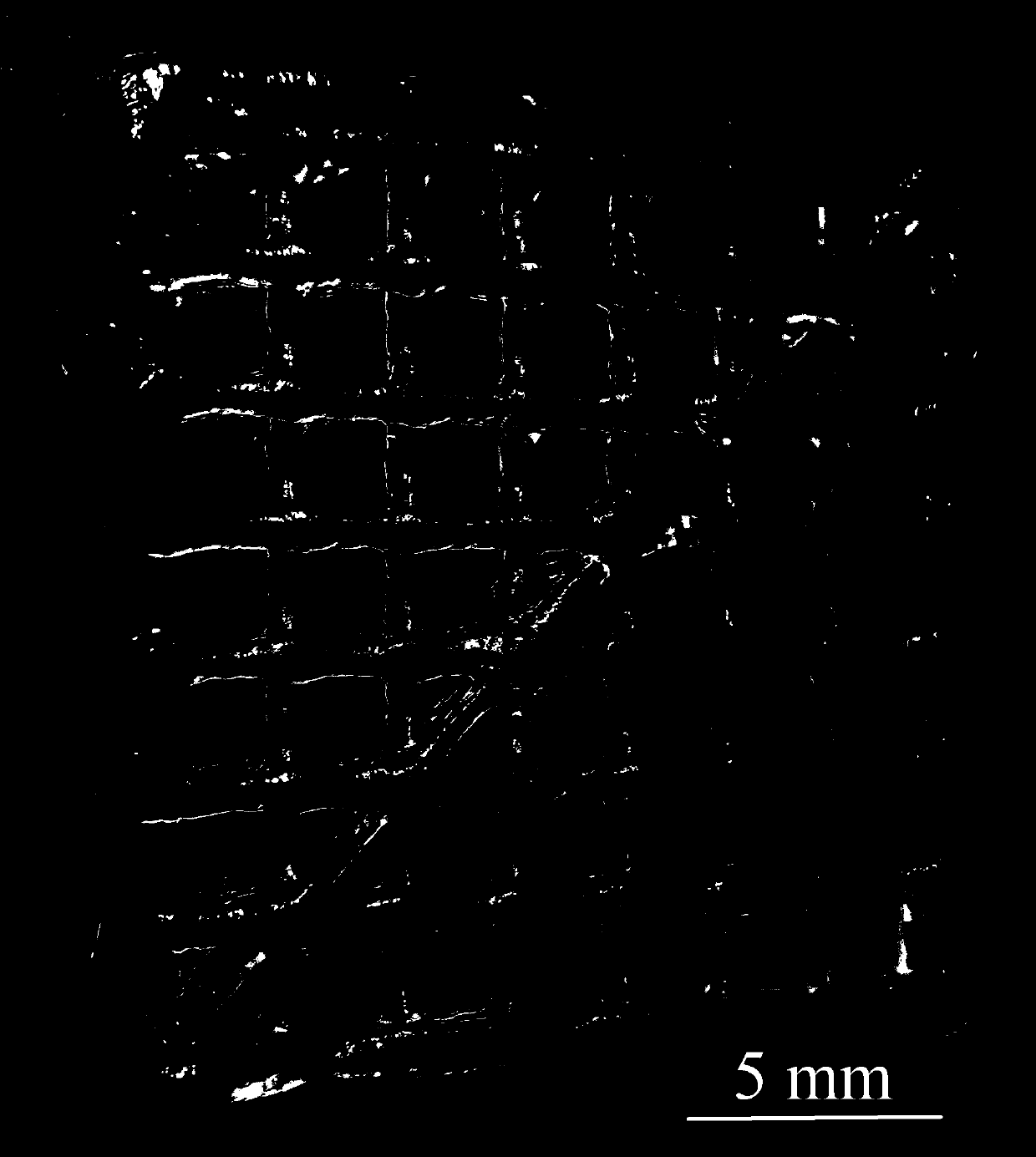

Image

Examples

Embodiment Construction

[0040] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0041] A preparation method of ultrapure nanocellulose bioprinting gel ink, comprising the following steps:

[0042] (1) Stir 100 grams of bleached pulp fiber in 3 liters of sterile water to disperse evenly, add 10 grams of sodium hydroxide and 2 grams of hydrogen peroxide, stir evenly, and sterilize under high pressure for 60 minutes;

[0043] Dissolve 10 grams of xyloglucan in 1 liter of sterile water and autoclave for 30 minutes;

[0044] Dissolve 5 g of gel enhancer in 100 ml sterile water and autoclave for 20 min.

[0045] (2) The pulp fiber in step (1) is filtered and washed with sterile water until the pH is neutral.

[0046] (3) Disperse the cleaned pulp fibers in step (2) in 3 liters of sterile water, add 30 grams of hydrochloric acid, stir well, and sterilize by autoclaving for 60 minutes.

[0047] (4) Filter and wash the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com