Preparation method of saline-alkali-resistant composite plugging agent

A technology of water blocking agent and salt and alkali resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor water blocking effect, poor temperature resistance and salt and alkali resistance, and achieve strong acid and alkali resistance Excellent heat resistance, acid and alkali resistance, and enhanced water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

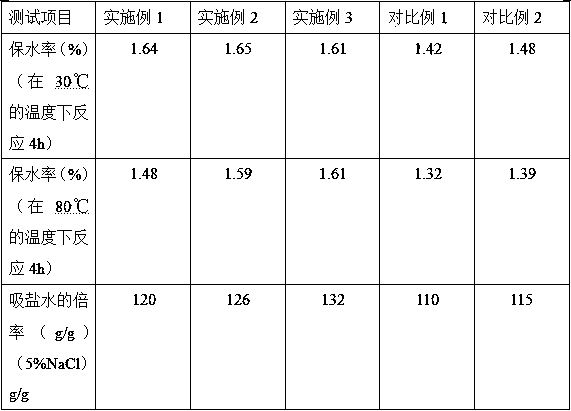

Examples

preparation example Construction

[0028] Preparation of spray-dried powder: according to CaO / SiO 2 The molar ratio is 2:1, weigh an appropriate amount of calcium nitrate tetrahydrate and silica sol, dissolve calcium nitrate tetrahydrate into a 1mol / L calcium nitrate solution with deionized water, and mix and stir the calcium nitrate solution and silica sol for 1 hour to obtain a mixed liquid, and then the mixed solution is spray-dried at a spray-drying rate of 1000mL / h to obtain a spray-dried powder;

[0029] Preparation of ball mill powder:

[0030]Put the spray-dried powder obtained above into a sintering furnace, pre-sinter at 700°C for 10 minutes, mix the pre-sintered product with methyl cellulose and calcium phosphate in a mass ratio of 100:3:2, and then ball mill for 2 hours to obtain ball mill powder;

[0031] Preparation of porous dicalcium silicate powder:

[0032] Mix the ball mill powder and deionized water at a mass ratio of 10:1, stir and mix for 10 minutes, put it into a microwave sintering fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com