Preparation method for metal-free perovskite quantum dots DABCO-NH4X3 (X=Cl, Br, I)

A perovskite and quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., to achieve the effects of low cost, simple operation and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

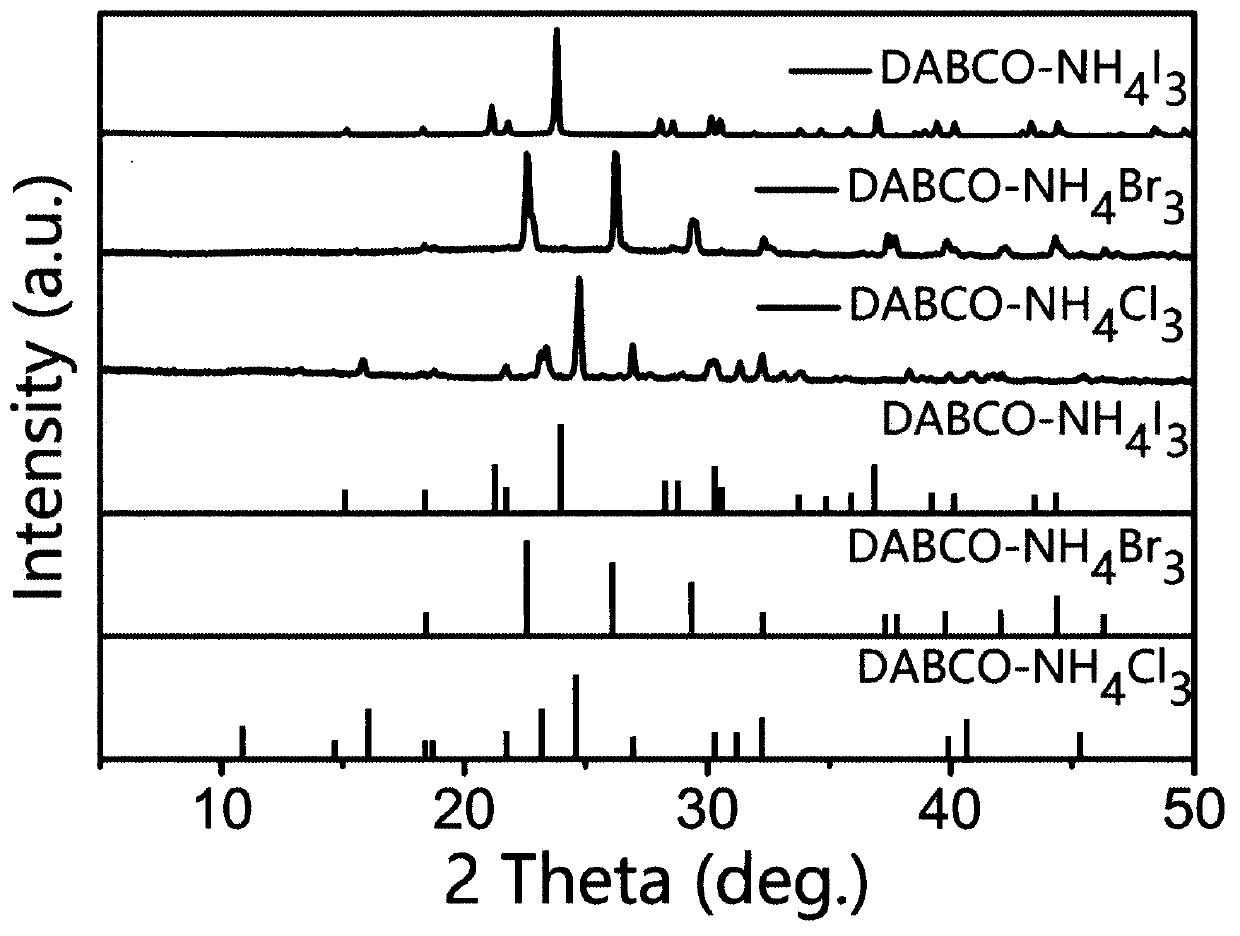

[0019] Add 20mL N-N dimethylformamide and 5mL hydrochloric acid to a 100mL single-necked flask, weigh 10mmol ammonium chloride solid, stir to dissolve it completely, then add 2mL oleic acid and 1mL n-octylamine to it, stir for 30 minutes, and finally Weigh 10mmol of DABCO solid and dissolve it in N-N dimethylformamide, then add it dropwise to the precursor solution, continue to stir for 30 minutes, add 40mL of ethyl acetate to it, a white precipitate will be produced rapidly, and the solution will be centrifuged at 12000r / min at high speed Wash and centrifuge in the machine for 3 times, and dry the solid after washing and centrifuging in vacuum at 40°C for 6 hours to obtain DABCO-NH 4 Cl 3 finished product. figure 1 It can be seen from the XRD pattern that all its diffraction peaks correspond to the standard card, further confirming that DABCO-NH was successfully prepared 4 Cl 3 finished product. and figure 2 DABCO-NH 4 Cl 3 TEM image of perovskite, DABCO-NH can be cle...

Embodiment 2

[0021] Add 20mL N-N dimethylformamide and 5mL hydrobromic acid to a 100mL single-necked flask, weigh 10mmol ammonium bromide solid, stir to dissolve it completely, then add 2mL oleic acid and 1mL n-octylamine to it, and stir for 30 minutes , and finally weighed 10mmol of DABCO solid and dissolved it in N-N dimethylformamide and added it dropwise to the precursor solution. Stirring was continued for 30 minutes, and 40mL of ethyl acetate was added to it to rapidly produce white precipitate. Wash and centrifuge 3 times in a high-speed centrifuge, and dry the solid after washing and centrifuging in vacuum at 40°C for 6 hours to obtain DABCO-NH 4 Br 3 finished product. figure 1 It can be seen from the XRD pattern that all the diffraction peaks correspond to the standard card.

Embodiment 3

[0023] Add 20 mL of N-N dimethylformamide and 5 mL of hydroiodic acid to a 100 mL single-necked flask, and then add 2 mL of phosphoric acid to prevent I - Oxidation, weigh 10mmol ammonium chloride solid, stir to dissolve it completely, then add 2mL oleic acid and 1 mL n-octylamine to it, stir for 30 minutes, finally weigh 10mmol DABCO solid and dissolve it in N-N dimethylformamide Then add it dropwise to the precursor solution, continue to stir for 30 minutes, add 40mL ethyl acetate to it, quickly produce white precipitate, wash and centrifuge the solution 3 times in a 12000r / min high-speed centrifuge, and centrifuge the solid at 40 After vacuum drying at ℃ for 6 hours, DABCO-NH 4 I 3 finished product. figure 1 It can be seen from the XRD pattern that all the diffraction peaks correspond to the standard card.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com