Heavy metal curing agent based on polypropylene fiber and boiler ash and application of heavy metal curing agent

A technology of polypropylene fiber and boiler ash, applied in application, transportation and packaging, chemical instruments and methods, etc., can solve the threat of groundwater quality, pollute surrounding soil and other problems, achieve good curing effect, low price and good economic benefits and the effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

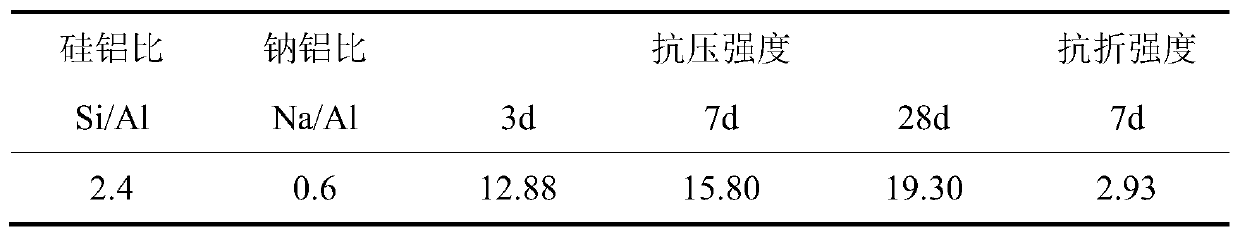

[0024] Under the conditions of different Si / Al molar ratios (2.4, 2.7, 3.0), Na / Al molar ratios (0.6, 0.7, 0.8), water-binder ratio 2.3, polypropylene fiber 0.3%, ash residue at 500r / min for 35min To prepare polypropylene fiber soil polymer, first mix boiler ash and polypropylene fiber, stir for 3 minutes, then add 10mol / L NaOH, water glass with a modulus of 3.3 and water, and continue stirring for 5 minutes to obtain a Geopolymer based on boiler ash and polypropylene fiber, then cured at 80°C for 24h to demould, then placed in a standard curing box at 20±2°C, relative humidity 95% for curing, measured after 3d, 7d and 28d respectively Compressive strength and 7d flexural strength.

[0025] Table 1 Compressive strength and flexural strength of test blocks under different Si / Al and Na / Al

[0026]

[0027]

Embodiment 2

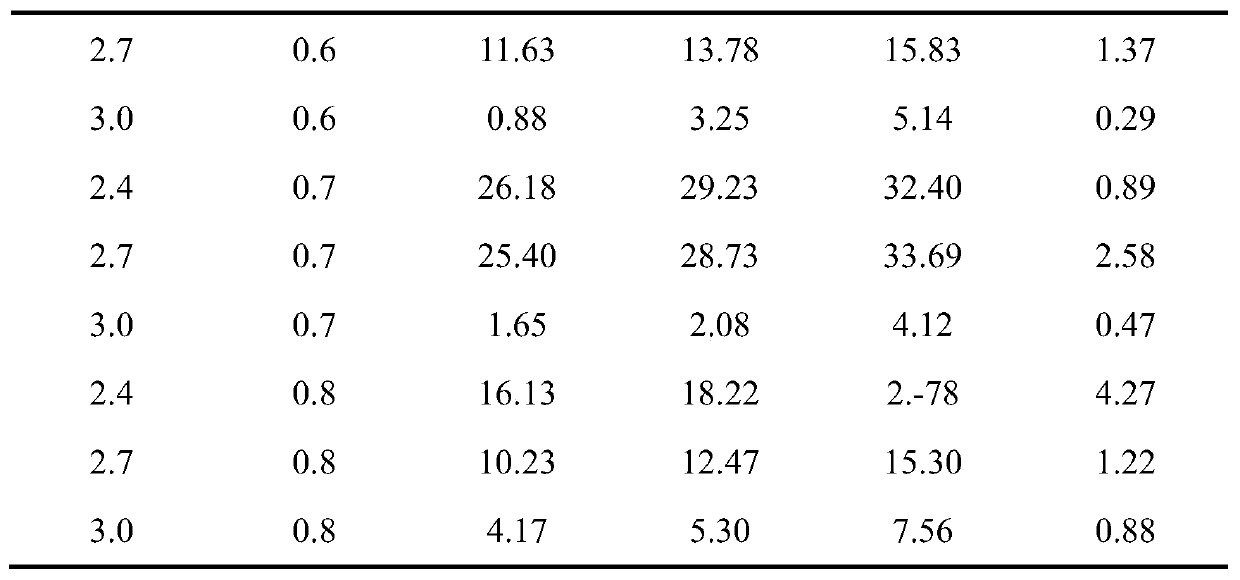

[0029] Under the mix ratio of Si / Al molar ratio 2.7, Na / Al molar ratio 0.7, and water-binder ratio 2.3, rice husk fiber and polypropylene fiber were selected to be mixed, and the dosages were 0, 0.1%, 0.3% and 0.5%, respectively. Boiler ash slag was prepared under the condition of 500r / min and the activation time was 35min to prepare geopolymer, after curing at 80°C for 24 hours, it was removed from the mold, and then put into a standard curing box at 20±2°C and relative humidity of 95% for curing. The compressive strength and 7d flexural strength were measured after 3d, 7d and 28d.

[0030] Table 2 Compressive strength and flexural strength of test blocks under different types of fibers

[0031]

Embodiment 3

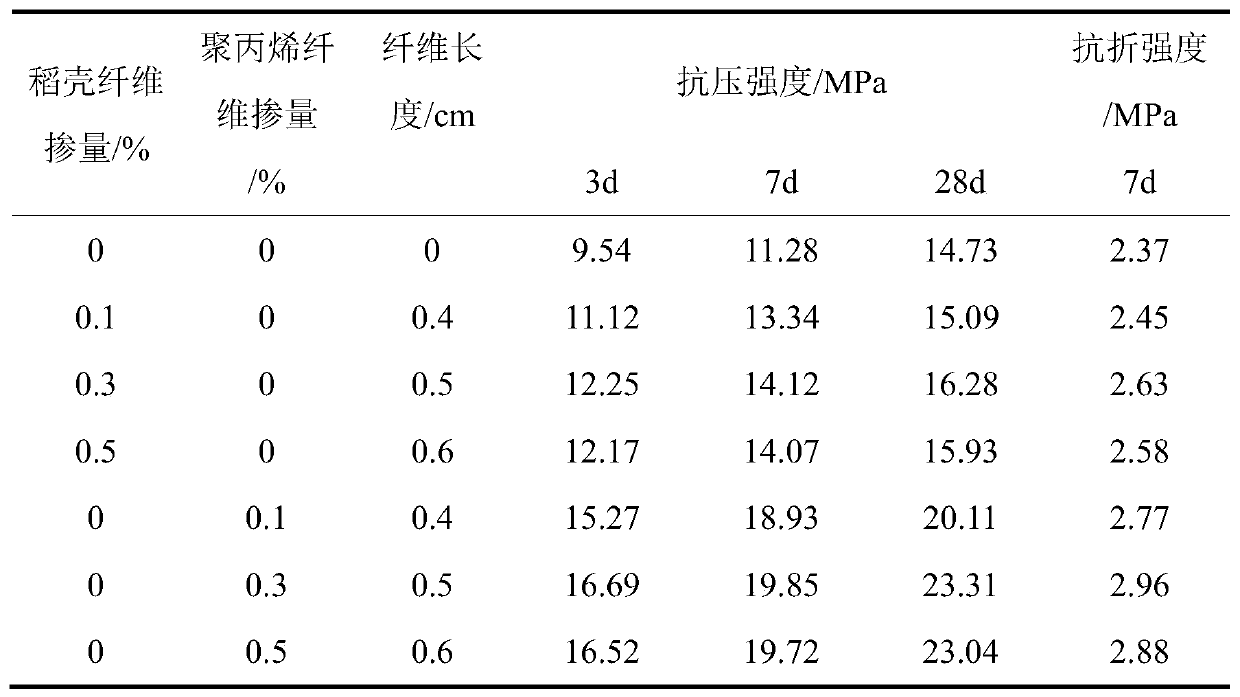

[0033]Under the mix ratio of Si / Al molar ratio 2.7, Na / Al molar ratio 0.7, water-binder ratio 2.3, polypropylene fiber content 0.3%, boiler ash slag activation time 35min at 500r / min, alkali activator NaOH concentration respectively 6, 8, 9, 10, 12mol / L, water glass modulus of 3.0, 3.1, 3.2, 3.3, 3.4 and 3.5 to prepare geopolymers, demould after curing at 80°C for 24 hours, and then put Put it into a standard curing box at 20±2°C and a relative humidity of 95% for curing, and measure the compressive strength and 7d flexural strength after 3d, 7d and 28d respectively.

[0034] Table 3 Compressive strength and flexural strength of test blocks under different alkali activator concentrations and water glass modulus

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com