Method for constructing yeast expression vector and preparing cellobiohydrolase by yeast expression vector and application thereof

A yeast expression vector and cellulase technology, applied in the field of genetic engineering, can solve problems such as wasting resources, polluting the environment, and harming animals, and achieve the effects of improving utilization rate, high activity, and increasing utilization channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Optimization of exo-cellulase gene fragments: According to the codon preference of Pichia pastoris and the characteristics of pPICZαA vector, the gene sequence of Lentinula edodes cellulase CEL7A (cel7A) mRNA, complete cds , GenBank: AF411250.1, https: / / www.ncbi.nlm.nih.gov / nuccore / AF411250.1 / ), optimize and add restriction endonuclease EcoR I and Xba I sites at both ends of the fragment And synthesize a new gene sequence such as SEQ ID NO.1.

[0038] Construction of the recombinant expression vector pPICZαA-Cel7A: Use EcoR I and Xba I restriction endonucleases to perform double enzyme digestion on the gene sequence such as the exo-cellulase gene fragment of SEQ ID NO.1 and the expression plasmid pPICZαA, respectively. The system is: 5 μL of 10×QuickCut buffer, 1 μL of EcoR I, 1 μL of Xba I, 8 μL of plasmid, 35 μL of sterilized water, and incubate at 37°C for 15 minutes. Gel recovery of exo-cellulase gene fragment; purify digested pPICZαA plasmid; take 4 μl of exo-cell...

Embodiment 2

[0040] Transform Pichia pastoris: use the restriction endonuclease Sac I to linearize the recombinant expression vector pPICZαA-Cel7A, the enzyme digestion system is: 10×QuickCut buffer 5 μL, Sac I 1 μL, plasmid 8 μL, sterile water 36 μL, 37 Incubate at ℃ for 15min. Use the PCR product purification kit to purify the digested product; use the electroporation instrument to transfer the linearized expression vector pPICZαA-Cel7A into Pichia pastoris X33 competent cells, and add sorbitol 0.5-1mol / L, bleomycin Culture in 0.1-1 μL / mLYPD medium (1% yeast extract, 2% peptone, 2% glucose), use pPICZαA vector primer: α-factor primer: 5′-TACTATTGCCAGCATTGCTGC-3′;

[0041] 3'AOX1 primer: 5'-GCAAATGGCATTCTGACATCC-3' by PCR (94°C for 1 minute pre-denaturation, 98°C for 10 seconds, 55°C for 15 seconds, 68°C for 1 minute, cycle 30 times, 72°C for 5 minutes), Screen positive clones. Pick 1 white colony and add it to 2 ml of YPD medium, shake overnight at 30°C. Transfer the whole bacterial s...

Embodiment 3

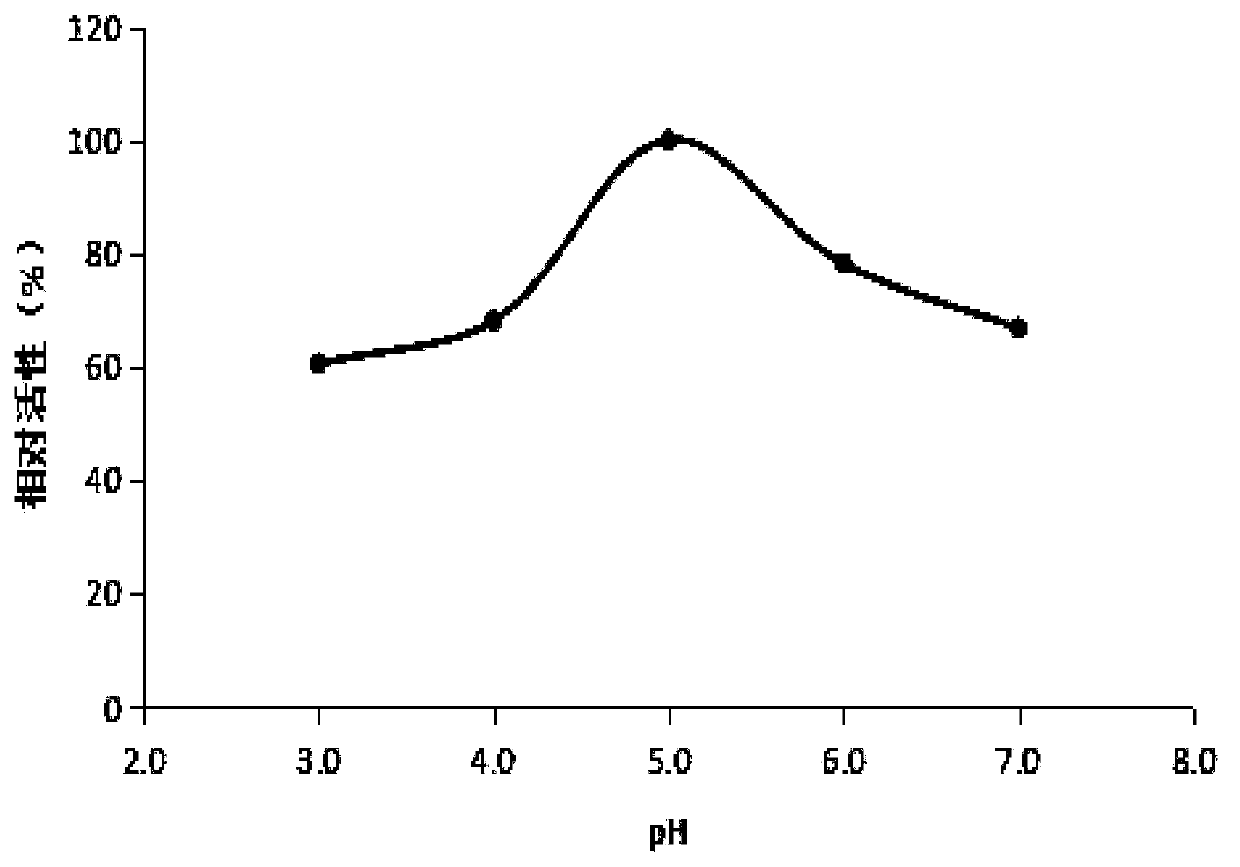

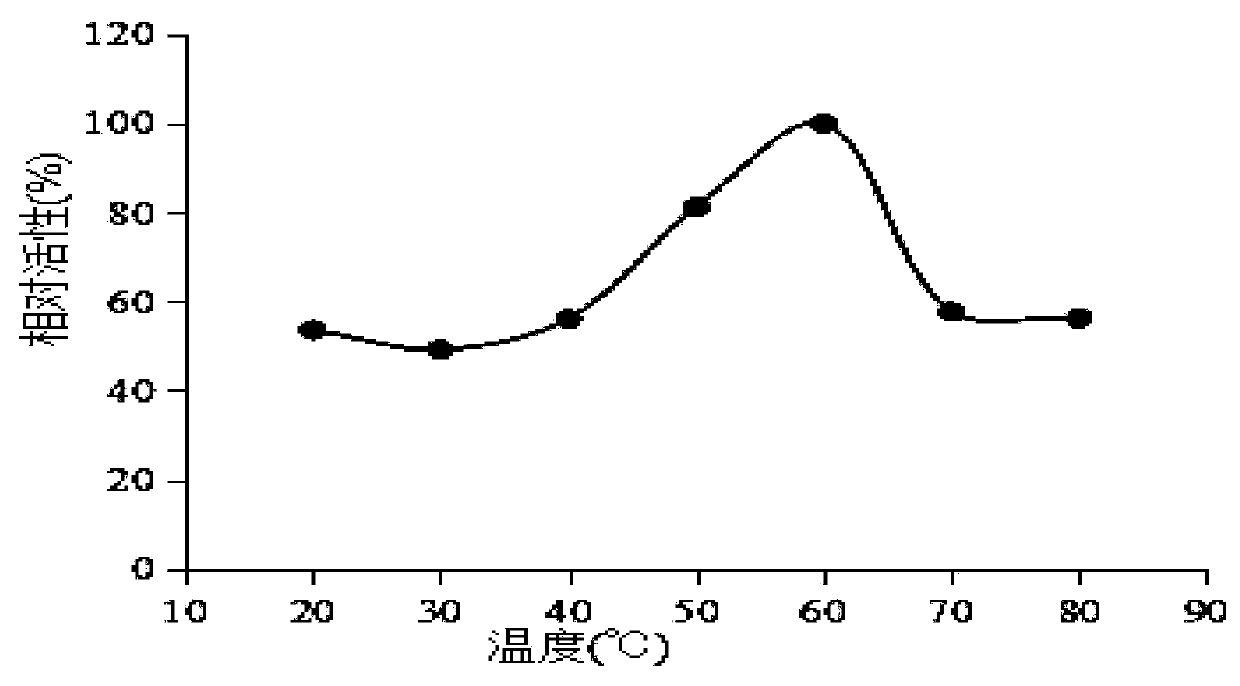

[0046] Characteristic identification of exo-cellulase: the reaction system of 5-10 micrograms of exo-cellulase prepared in Example 2, 1% microcrystalline cellulose, and 100 mM citric acid buffer (pH 3.0-7.0) was placed in Incubate in a water bath at 40° C. with shaking for 1 h, measure the concentration of reducing sugar, and determine the dependence of exo-cellulase on pH. The results showed that the exo-cellulase had the strongest activity at pH 5.0 ( figure 2 ). Similarly, the reaction system was placed in a buffer solution with a pH of 5.0, shaken and incubated at 20-80°C for 1 hour, and the reducing sugar concentration was measured to determine the temperature dependence of the exo-cellulase. The results show that the optimum temperature of the exo-cellulase in the present invention is 60°C ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com