Preparation method of antifouling and anticorrosive tablecloth material

A technology for anti-corrosion and tablecloths, applied in anti-coloring pollution/anti-fouling fibers, liquid-repellent fibers, fiber types, etc., can solve the problems of poor waterproof and oil-proof performance, damage, etc., and achieve good chemical resistance stability , not easy to be destroyed, good physical and mechanical properties and dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

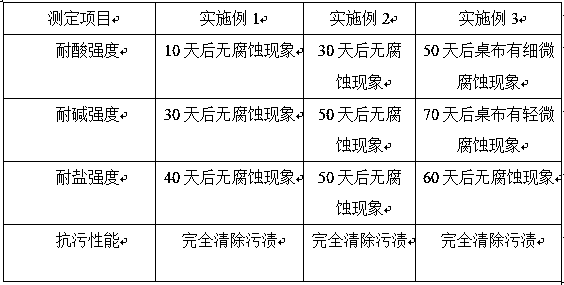

Examples

Embodiment 1

[0041] In parts by weight, weigh 40 parts of tetraethyl orthosilicate, 20 parts of ammonia water with a mass concentration of 1%, 30 parts of absolute ethanol, and 60 parts of deionized water, add absolute alcohol to deionized water, and Stir at a speed of 120r / min for 5min to obtain an ethanol solution, add ammonia water to the ethanol solution, stir at a speed of 200r / min for 10min in a water bath at 40°C, keep warm to obtain a reaction solution, and dilute ethyl orthosilicate at a rate of 40mL / min Add the reaction solution evenly at a flow rate, stir and react at 240r / min in a water bath at 40°C for 2h to obtain the reaction product, put the reaction product in a centrifuge at room temperature and centrifuge at 3500r / min for 10min, take the lower layer to obtain For solid deposits, wash the solid deposits with absolute ethanol for 3 times, then wash with deionized water for 3 times, and dry them in an oven at 120°C for 4 hours to obtain nano-silica powder with an average par...

Embodiment 2

[0043]In parts by weight, weigh 45 parts of tetraethyl orthosilicate, 25 parts of ammonia water with a mass concentration of 1%, 35 parts of absolute ethanol, and 70 parts of deionized water. Stir at a speed of 130r / min for 7min to obtain an ethanol solution, add ammonia water to the ethanol solution, stir for 13min at a speed of 210r / min in a water bath at 45°C, keep warm to obtain a reaction solution, and dilute ethyl orthosilicate at 50mL / min Add the reaction solution evenly at a flow rate, stir and react at 260r / min in a water bath at 45°C for 3h to obtain the reaction product, place the reaction product in a centrifuge at room temperature and centrifuge at a speed of 3750r / min for 13min, take the lower layer to obtain For solid deposits, wash the solid deposits with absolute ethanol for 4 times, then wash them with deionized water for 4 times, and dry them in an oven at 130°C for 5 hours to obtain nano-silica powder with an average particle size of 70nm , and then weighed...

Embodiment 3

[0045] In parts by weight, weigh 50 parts of tetraethyl orthosilicate, 30 parts of ammonia water with a mass concentration of 1%, 40 parts of absolute ethanol, and 80 parts of deionized water. Stir at a speed of 140r / min for 10min to obtain an ethanol solution, add ammonia water to the ethanol solution, stir for 15min at a speed of 220r / min in a water bath at 50°C, and keep warm to obtain a reaction solution. Add the reaction solution evenly at a flow rate, stir and react at 280r / min in a water bath at 50°C for 4h to obtain the reaction product, put the reaction product in a centrifuge at room temperature and centrifuge at 4000r / min for 15min, take the lower layer to obtain For solid deposits, wash the solid deposits with absolute ethanol for 5 times, then wash them with deionized water for 5 times, and dry them in an oven at 140°C for 6 hours to obtain nano-silica powder with an average particle size of 80nm , and then in parts by weight, respectively weigh 50 parts of alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com