Novel hyaluronic acid flowing gel and preparation method and application thereof

A technology of hyaluronic acid and gel, which is applied in pharmaceutical formulations, medical preparations containing active ingredients, medical science, etc., can solve the problems of anti-adhesion and poor wound healing, achieve good bioadhesion, and promote wound healing , Excellent biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Dissolve 5g of hyaluronic acid powder (molecular weight: 500-2000kDa) in 500mL of water, stir until completely dissolved at room temperature, and prepare a hyaluronic acid solution;

[0041] Step 2: Use a homogenizer to disperse hyaluronic acid evenly in water, then slowly add 1M HCl to adjust the pH of the solution to pH<5. Divide the hyaluronic acid solution into centrifuge bottles and centrifuge to remove air bubbles in the solution. The hyaluronic acid solution after removing the air bubbles is divided into weighing bottles, and the lid is closed and sealed with a parafilm;

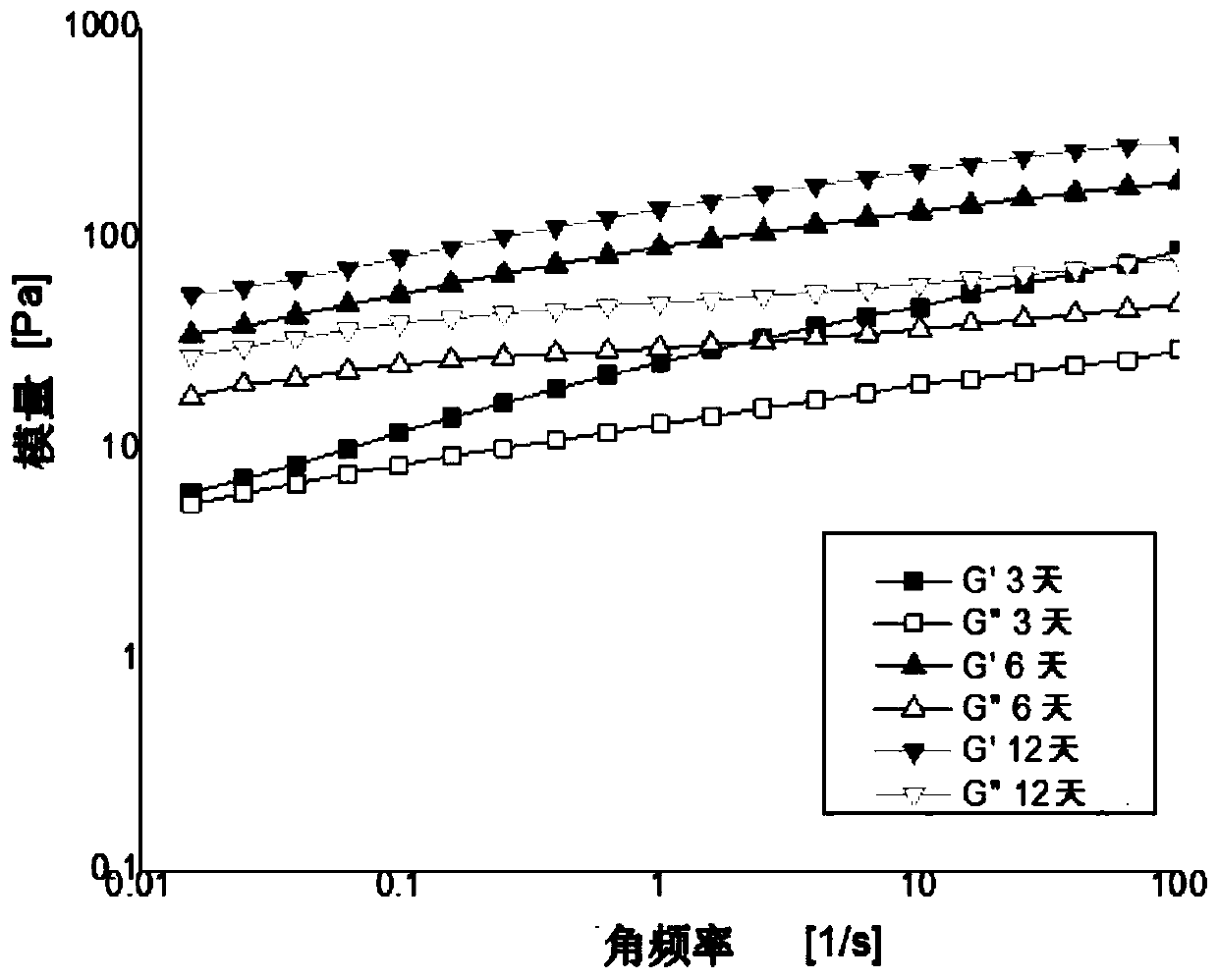

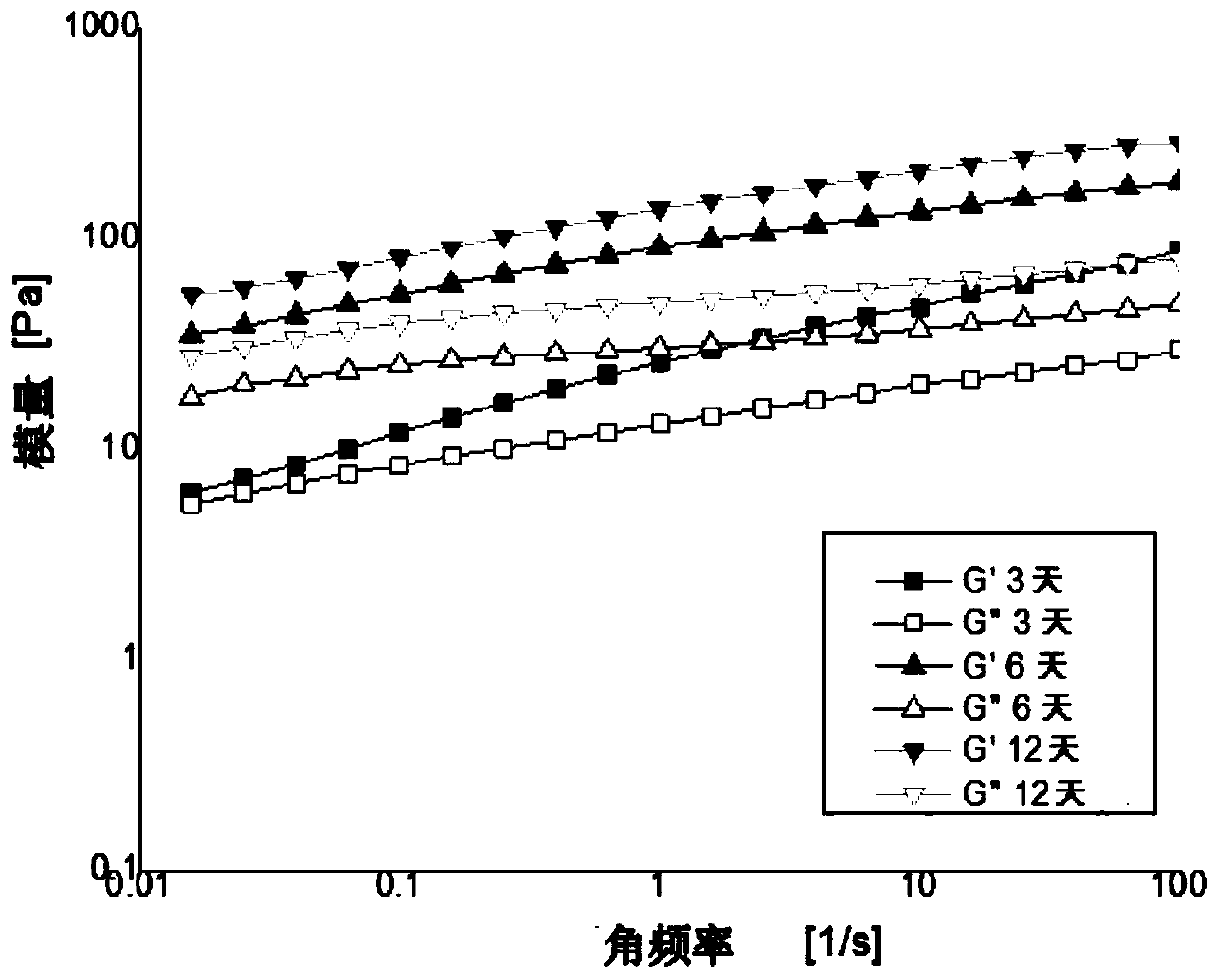

[0042] Step 3: Put the subpackaged solution obtained in Step 2 into a -20°C refrigerator and freeze for 3 days, then take out the weighing bottle and thaw for 6 hours, repeat the freezing and thawing process 3 times, and obtain an acidic freeze-thawed hyaluronic acid gel ;

[0043] Step 4: Transfer the acidic frozen-thawed hyaluronic acid gel obtained in step 3 to a dialysis bag and d...

Embodiment 2

[0047] Step 1: Dissolve 5g of hyaluronic acid powder (molecular weight: 500-2000kDa) in 500mL of water, stir until completely dissolved at room temperature, and prepare a hyaluronic acid solution;

[0048] Step 2: Use a homogenizer to uniformly disperse hyaluronic acid in water, and then slowly add 1M HCl to adjust the pH of the solution to be the same as that in Example 1. Divide the hyaluronic acid solution into centrifuge bottles and centrifuge to remove air bubbles in the solution. The hyaluronic acid solution after removing the air bubbles is divided into weighing bottles, and the lid is closed and sealed with a parafilm;

[0049] Step 3: Put the subpackaged solution obtained in Step 2 into a -20°C refrigerator and freeze for 6 days, then take out the weighing bottle and thaw for 6 hours, repeat the freezing and thawing process 3 times, and obtain an acidic freeze-thawed hyaluronic acid gel ;

[0050] Step 4: Transfer the acidic frozen-thawed hyaluronic acid gel obtaine...

Embodiment 3

[0054] Step 1: Dissolve 5g of hyaluronic acid powder (molecular weight: 500-2000kDa) in 500mL of water, stir until completely dissolved at room temperature, and prepare a hyaluronic acid solution;

[0055] Step 2: Use a homogenizer to uniformly disperse hyaluronic acid in water, and then slowly add 1M HCl to adjust the pH of the solution to be the same as that in Example 1. Divide the hyaluronic acid solution into centrifuge bottles and centrifuge to remove air bubbles in the solution. The hyaluronic acid solution after removing the air bubbles is divided into weighing bottles, and the lid is closed and sealed with a parafilm;

[0056] Step 3: Put the aliquoted solution obtained in Step 2 into a -20°C refrigerator and freeze for 12 days, then take out the weighing bottle and thaw for 6 hours, repeat the freezing and thawing process 3 times, and obtain an acidic freeze-thawed hyaluronic acid gel ;

[0057] Step 4: Transfer the acidic frozen-thawed hyaluronic acid gel obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com