Colon target prepn. contg. 5-aminosalicylic acid, and its prepn. method

A technology of aminosalicylic acid and colon targeting, which is applied in the field of pharmaceutical preparations in medical engineering, and can solve the problems of inability to achieve colon targeting, high local concentration, and fast drug release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

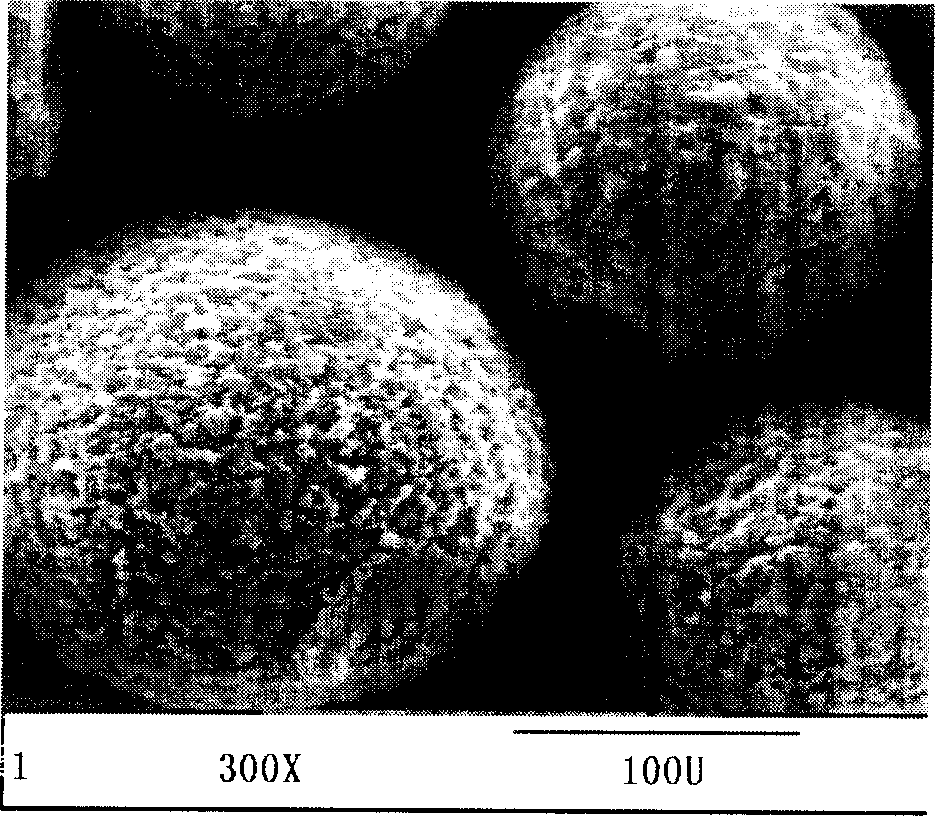

[0026] 2g of chitosan (molecular weight: 300,000, degree of deacetylation: 93.2%) was dissolved in 100mL of 0.2mol / L acetic acid solution to prepare a chitosan solution. Add 50 mg of 5-aminosalicylic acid into 1 mL of pure water for ultrasonic dispersion for 20 seconds. Take 10mL chitosan solution and disperse it into the ultrasonically dispersed 5-aminosalicylic acid as the water phase. Take 50mL of liquid paraffin (oil phase) and add it to the reactor, add 1mL of Span 80 and 1mL of Tween 80, stir at a speed of 600 rpm, and disperse for 10 minutes, then add the above prepared 5-aminosalicyl Acidic chitosan solution (water phase), continued to stir and disperse for 30 minutes with the same rotating speed to form a stable emulsion; to this emulsion, add 40 mL of ammonium sulfate solution with a concentration of 10% (w / v), and continue to stir for 1 hour stop after. Centrifuge, pour out the upper liquid, separate the microspheres precipitated by ammonium sulfate in the lower l...

Embodiment 2

[0034] 3g of chitosan (molecular weight: 550,000, degree of deacetylation: 86.3%) was dissolved in 100mL of 0.25mol / L propionic acid solution to prepare a chitosan solution. Add 30 mg of 5-aminosalicylic acid into 1 mL of pure water for ultrasonic dispersion for 20 seconds, take 10 mL of chitosan solution, and disperse it into the ultrasonically dispersed 5-aminosalicylic acid as the water phase. Take 80mL of peanut oil (oil phase) and add it to the reactor, add 0.5mL of Span 20, stir at a speed of 1000 rpm, and after dispersing for 10 minutes, add the above prepared chitosan dispersed with 5-aminosalicylic acid Solution (aqueous phase), after stirring and dispersing at the same speed for 30 minutes, add 100 mL of ammonium sulfate solution with a concentration of 20% (w / v), and stop stirring for 1 hour. After centrifugal separation, the precipitates are fully washed with pure water, petroleum ether and absolute ethanol in turn, and vacuum-dried at room temperature to obtain th...

Embodiment 3

[0037] 4g chitosan (molecular weight 780,000, deacetylation degree 77.9%) was dissolved in 100mL 0.25mol / L lactic acid solution to prepare chitosan solution. Add 10 mg of 5-aminosalicylic acid into 1 mL of pure water for ultrasonic dispersion for 20 seconds, take 10 mL of chitosan solution, and disperse into the ultrasonically dispersed 5-aminosalicylic acid as the water phase. Take 150mL soybean oil (oil phase) and add it to the reactor, add 1mL Span 60, stir at a speed of 1500 rpm, and after dispersing for 10 minutes, add the above prepared chitosan dispersed with 5-aminosalicylic acid Solution (water phase), after stirring and dispersing at the same speed for 30 minutes, add 200 mL of ammonium sulfate solution with a concentration of 50% (w / v), continue stirring for 1 hour and stop. After centrifugal separation, the precipitates are fully washed with pure water, petroleum ether and absolute ethanol in turn, and vacuum-dried at room temperature to obtain the chitosan microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com