Preparation method and application of visible light response type Zn2SnO4/ZnO/SnO2 composite photocatalytic material

A composite photocatalysis and visible light technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve application limitations, high intrinsic recombination rate of photogenerated carriers and other problems, to achieve the effect of no secondary pollution, simple and fast preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

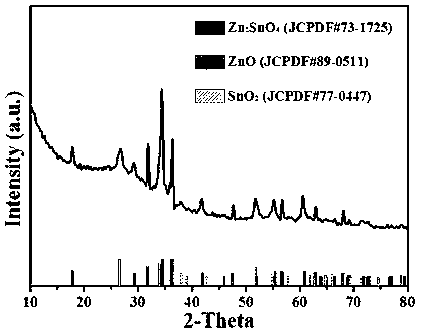

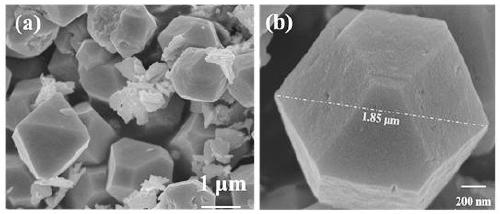

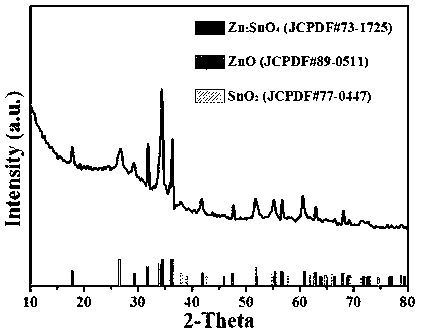

[0022] see Figure 1-2 , first use an analytical balance to weigh 1.7571g SnCl 4 ·5H 2 Add O to a beaker, add 50mL of deionized water, and stir it with a stirrer to completely dissolve it. Under stirring conditions, 0.3415g ZnCl 2 added to the above solution. The reaction was continued for 30 min while stirring, and 15 mL of NaOH solution with a concentration of 4 mol / L was added dropwise, and the resulting solution was alkaline. After continuing to stir for 1 h, the resulting mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and hydrothermally reacted in a constant temperature drying oven at 180° C. for 24 h. Then cool at room temperature. After cooling to room temperature, filter and wash with water, and dry overnight at 60°C in a blast drying oven. The dried sample was ground in agate and calcined at 700°C for 6 hours to obtain Zn 2 SnO 4 / ZnO / SnO 2 composite photocatalyst. After 100 minutes of natural light irradiation, t...

Embodiment 2

[0024] see Figure 1-2 , first use an analytical balance to weigh 1.7571g SnCl 4 ·5H 2 Add O to a beaker, add 50mL of deionized water, and stir it with a stirrer to completely dissolve it. Under stirring conditions, 0.683g ZnCl 2 added to the above solution. The reaction was continued for 30 min while stirring, and 15 mL of NaOH solution with a concentration of 4 mol / L was added dropwise, and the resulting solution was alkaline. After continuing to stir for 1 h, the resulting mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and hydrothermally reacted in a constant temperature drying oven at 180° C. for 24 h. Then cool at room temperature. After cooling to room temperature, filter and wash with water, and dry overnight at 60°C in a blast drying oven. The dried sample was ground in agate and calcined at 700°C for 6 hours to obtain Zn 2 SnO 4 / ZnO / SnO 2 composite photocatalyst. After 100 minutes of natural light irradiation, th...

Embodiment 3

[0026] see Figure 1-2 , first use an analytical balance to weigh 1.7571g SnCl 4 ·5H 2 Add O to a beaker, add 50mL of deionized water, and stir it with a stirrer to completely dissolve it. Under stirring conditions, 1.0245g ZnCl 2 added to the above solution. The reaction was continued for 30 min while stirring, and 15 mL of NaOH solution with a concentration of 4 mol / L was added dropwise, and the resulting solution was alkaline. After continuing to stir for 1 h, the resulting mixed solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and hydrothermally reacted in a constant temperature drying oven at 180° C. for 24 h. Then cool at room temperature. After cooling to room temperature, filter and wash with water, and dry overnight at 60°C in a blast drying oven. The dried sample was ground in agate and calcined at 700°C for 6 hours to obtain Zn 2 SnO 4 / ZnO / SnO 2 composite photocatalyst. After 100 minutes of natural light irradiation, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com