Preparation method of copper metaphosphate as high-purity optical glass additive

A technology of copper metaphosphate and optical glass, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems that the purity of copper metaphosphate cannot meet the preparation requirements of infrared cut-off filters, etc., and achieve high yield and improved Economic benefits, the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

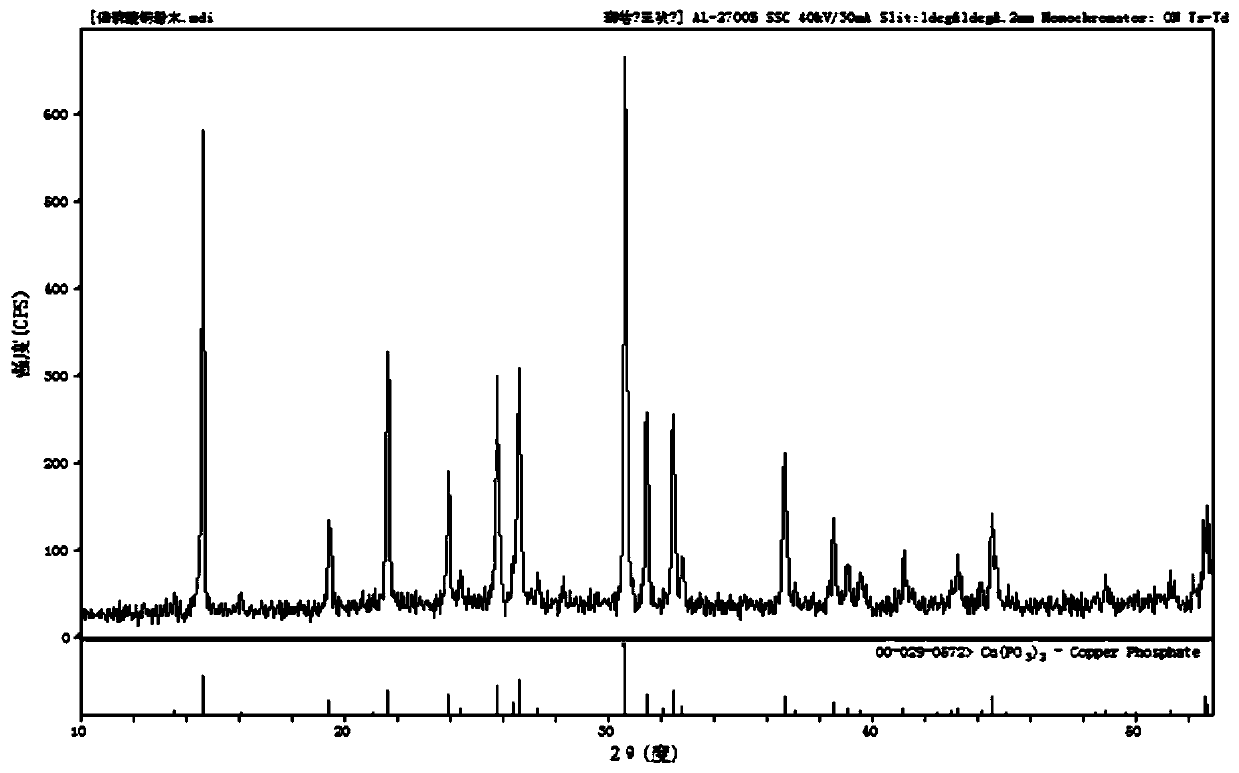

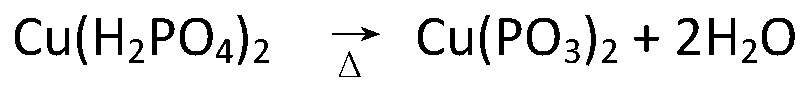

Image

Examples

Embodiment 1

[0057] Preparation method of high-purity optical glass additive copper metaphosphate:

[0058] Step 1, purifying copper sulfate raw material:

[0059] 1.1) Take industrial-grade copper sulfate raw materials and place them in an enamel reaction kettle, add deionized water and heat to 80°C to dissolve copper sulfate until the specific gravity of the copper sulfate solution is 1.12 (if the specific gravity is too large, it is not conducive to the adsorption and co-precipitation of Fe, Ni, Cr , Co, Mn, Ti, V, Pb), lower the temperature below 35°C, add hydrogen peroxide (the volume ratio of hydrogen peroxide to copper sulfate solution is 3:1500), stir evenly, let stand for 30 minutes, and dissolve the copper sulfate solution The ferrous ions in the solution are oxidized to ferric ions, adding a 10% barium hydroxide solution, adjusting the pH value to 3.5, stirring fully, and standing for 4 hours;

[0060] 1.2) Filter the solution obtained in step 1.1) into another container, add h...

Embodiment 2

[0082] The preparation method of high-purity optical glass additive copper metaphosphate:

[0083] Step 1, purifying copper sulfate raw material:

[0084]1.1) Take industrial-grade copper sulfate raw materials and place them in an enamel reaction kettle, add deionized water and heat to 90°C to dissolve copper sulfate until the specific gravity of the copper sulfate solution is 1.1, lower the temperature to below 35°C, add a small amount of hydrogen peroxide (hydrogen peroxide and The volume ratio of the copper sulfate solution is 1:1000), after stirring evenly, after standing for 40 minutes, adding a barium hydroxide solution with a concentration of 12%, adjusting the pH value to 4.2, stirring fully, and standing for 4 hours;

[0085] 1.2) Filter the solution obtained in step 1.1) into another container, add high-purity reagent sulfuric acid, adjust the pH value to 3, heat and concentrate the solution to a specific gravity of 1.3, and then remove the head and filter into anoth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com