Compound early strength agent for foaming cement and ultralight foaming cement

A technology of compounding early strength agent and foamed cement, applied in the field of building materials, can solve problems such as unsatisfactory early strength effect, and achieve the effect of solving utilization problems, reducing production cost and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

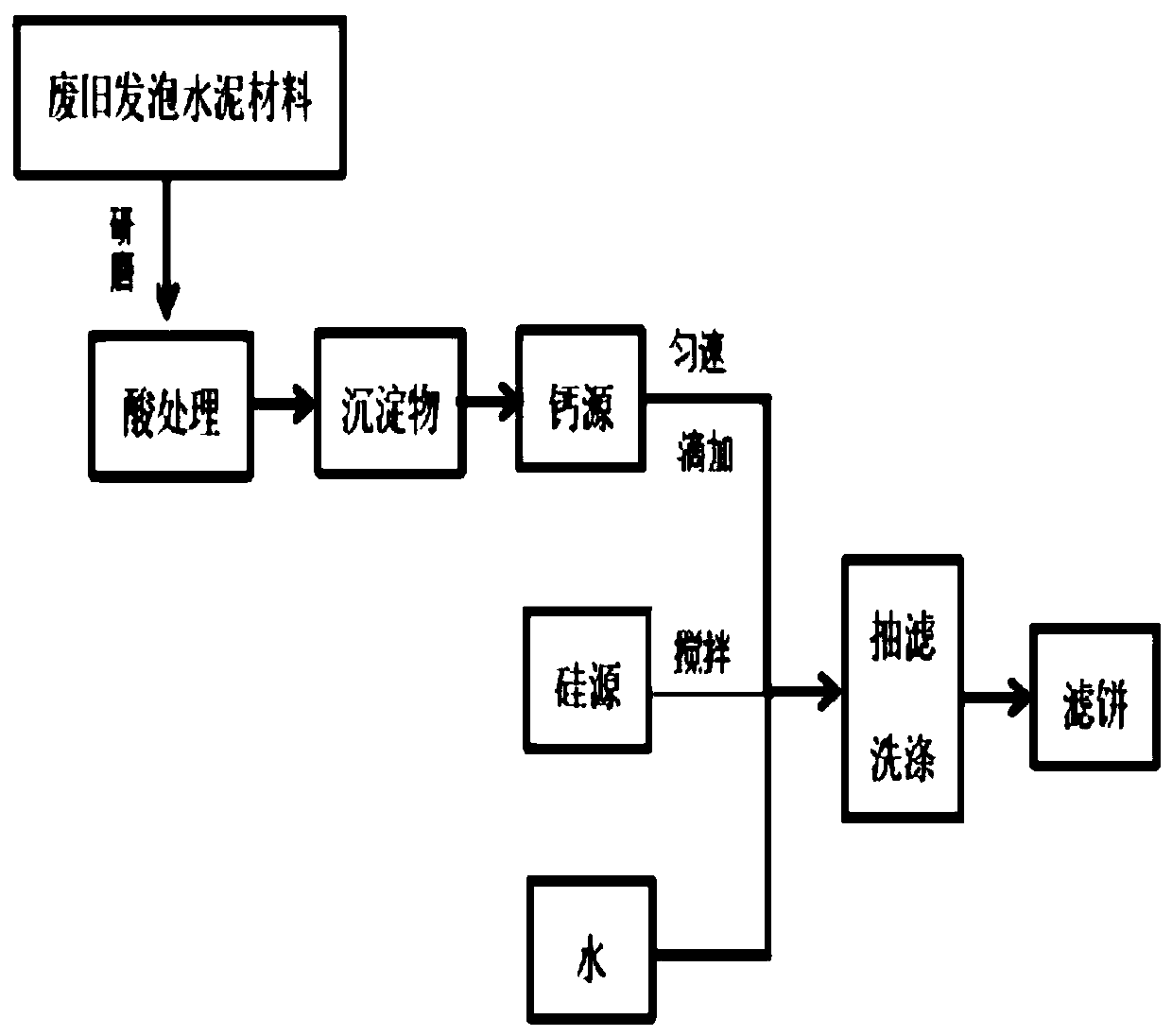

[0025] 1. Preparation of calcium silicate hydrate early strength agent

[0026] (1) Acid treatment of waste and old foamed cement materials:

[0027] A. The waste foamed cement material is pulverized by a ball mill, and the pulverized powder is soaked in 0.1mol / L acetic acid, wherein the mass ratio of the solid powder to the acetic acid solution is 1:3.

[0028]B. Filtrate the resulting treatment liquid, remove impurities by suction filtration, adjust the pH of the filtrate to 12 with NaOH solution, and remove impurities by suction filtration again to obtain waste liquid after acid treatment.

[0029] C, Utilize EDTA titration method to test Ca in the waste liquid of gained acid treatment 2+ Concentration, adjust the concentration to 0.1mol / L.

[0030] (2) Preparation of calcium silicate hydrate

[0031] The calcium silicate hydrate is prepared by chemical co-precipitation method, and the raw materials are divided into calcium source and silicon source, the calcium source i...

Embodiment 2

[0045] The foamed cement insulation board was prepared with reference to the method of Example 1, the difference being that the amount of self-made calcium silicate hydrate added when preparing the ultra-light foamed cement accounted for 30 wt% of the mass of the self-made additive.

Embodiment 3

[0047] Referring to the method of Example 1 to prepare foamed cement insulation boards, the difference is that the amount of self-made calcium silicate hydrate added when preparing ultra-light foamed cement accounts for 45 wt% of the mass of self-made additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com