Production system and method of fecal granular fertilizer

A production system and production method technology, applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems of dirty and smelly use, waste of resources, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

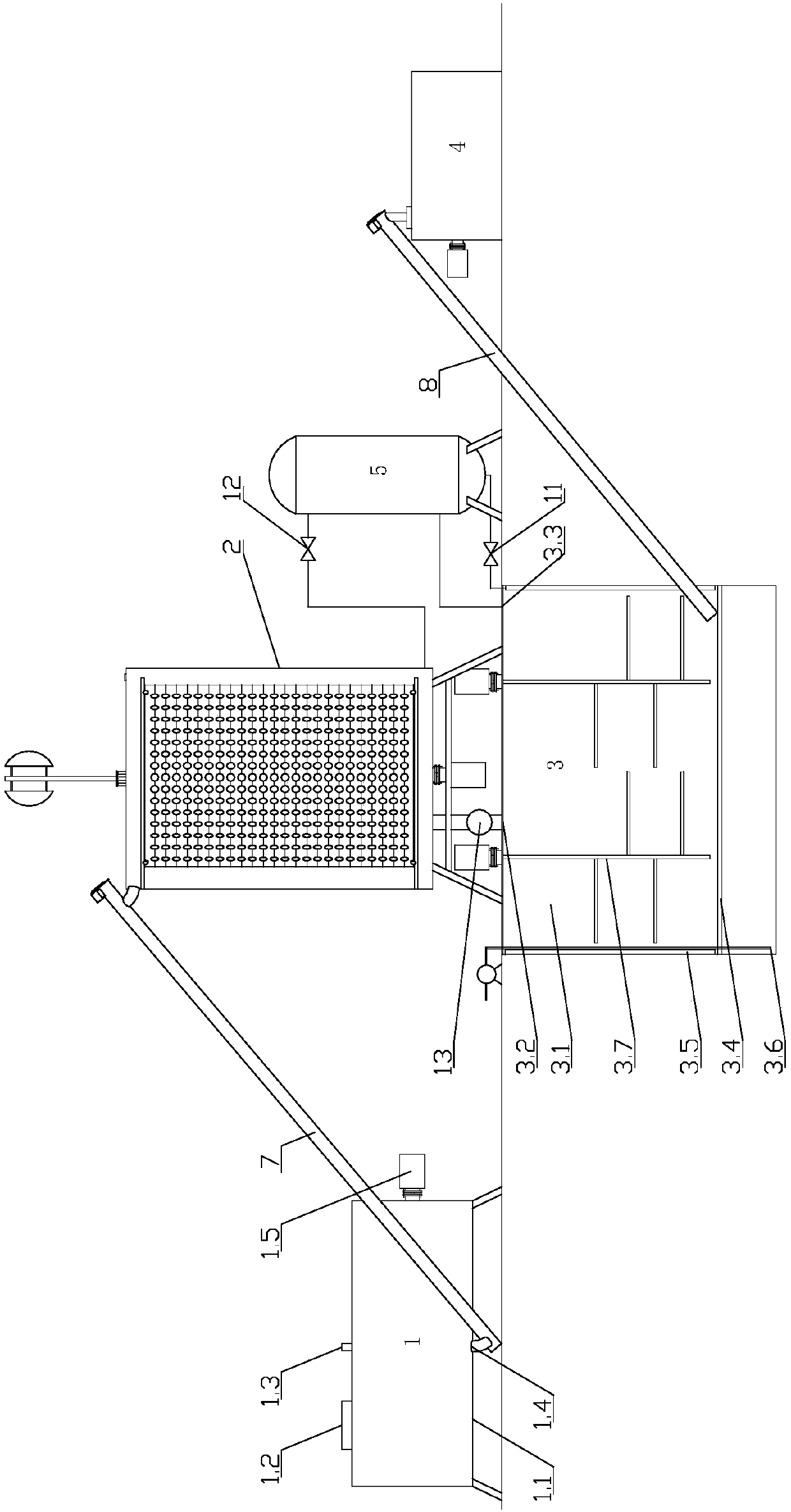

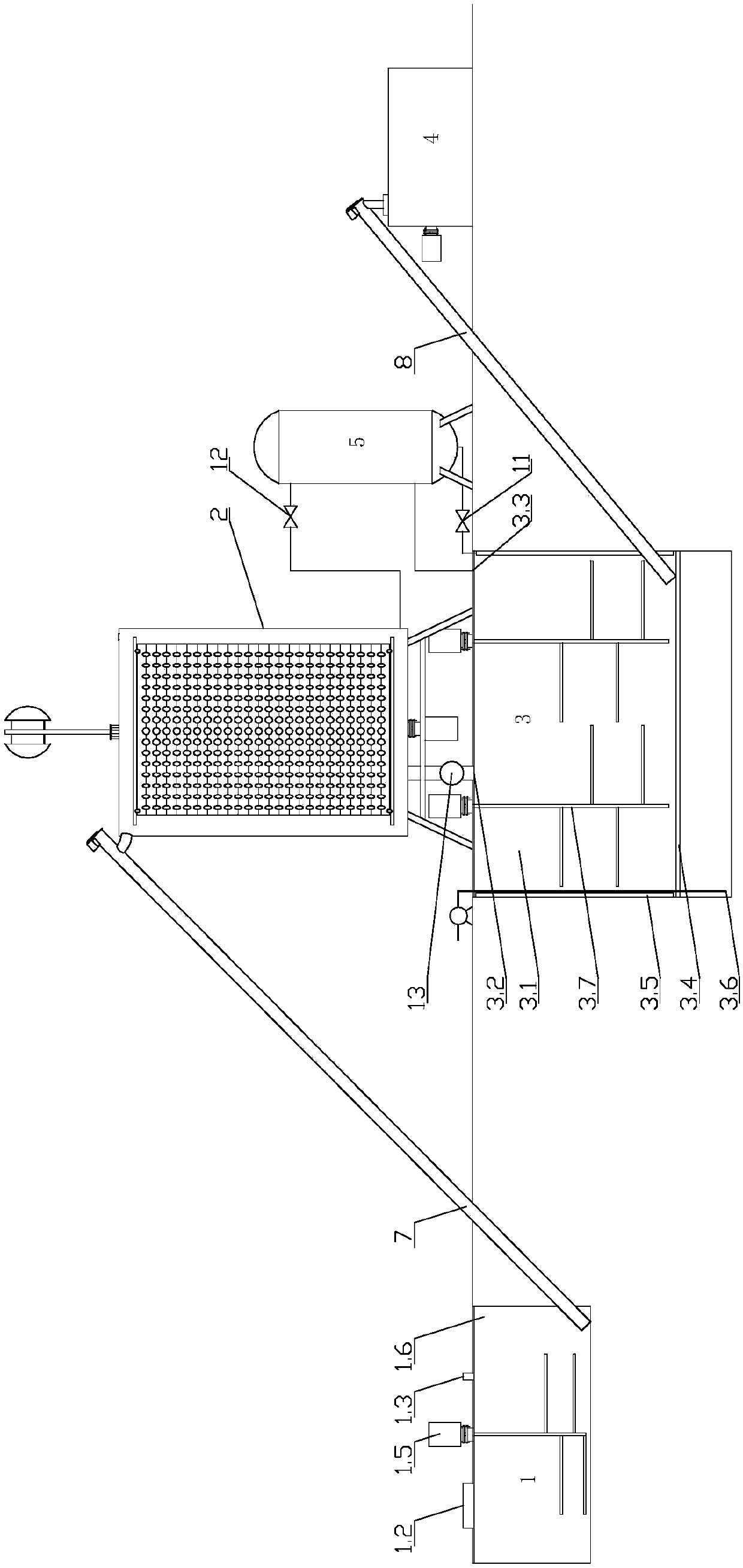

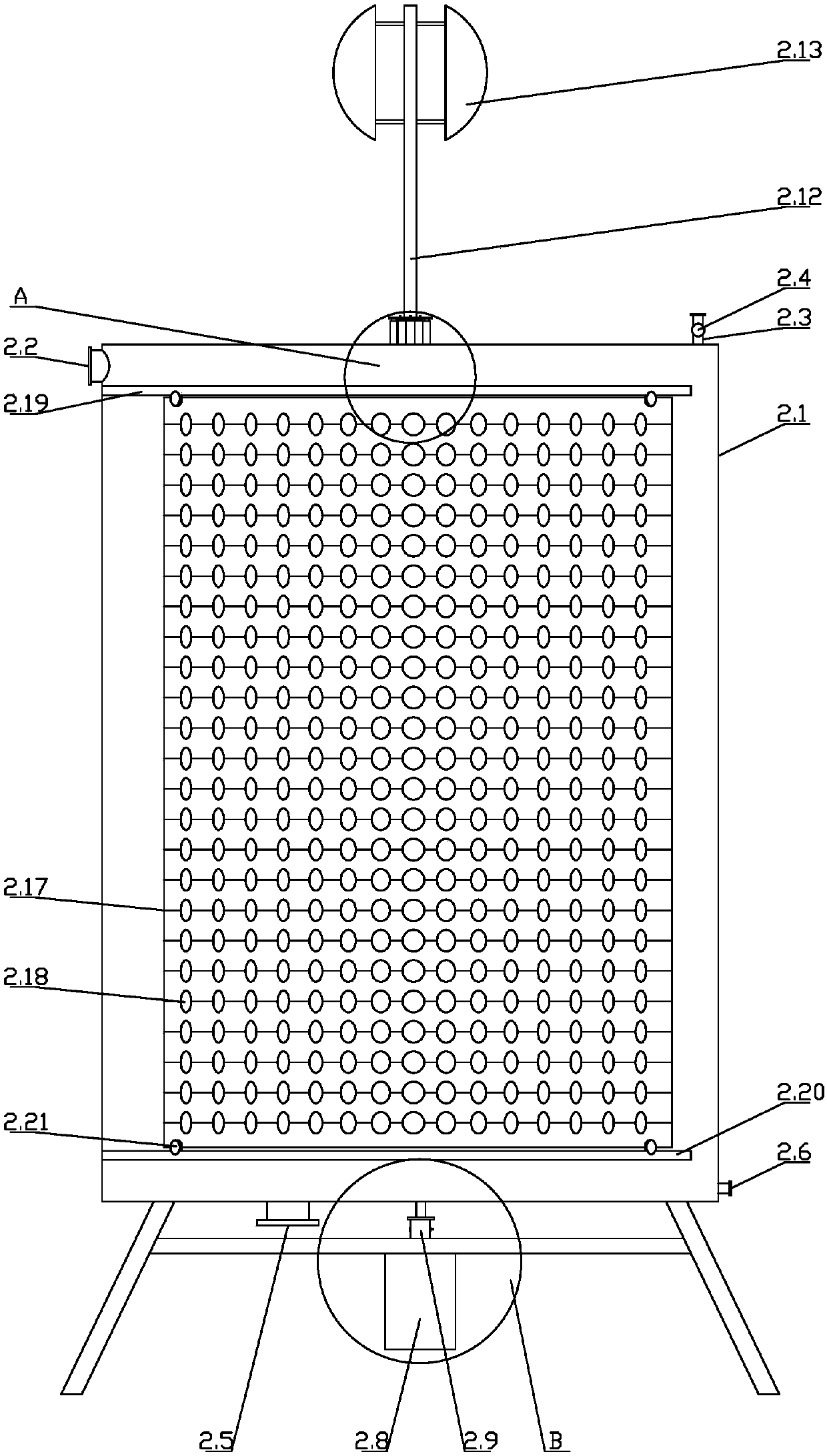

[0079] A kind of excrement granular fertilizer production system, it comprises material preparation device 1, cooking device 2, storage fermentation device 3, granulator 4, boiler 5 and controller 6; Steam generation device selects boiler 5 for use in the present embodiment, cooking device 2 is set Above the storage device 3, a first temperature sensor 9 is provided in the cooking device 2, and a second temperature sensor 10 is provided in the storage device 3; The feed inlet 2.2 is connected by the first screw conveyor 7, the cooking outlet 2.5 of the cooking device 2 is connected with the fermentation feed inlet 3.2 of the fermentation device 3 through a connecting pipe, and a discharger 13 is arranged on the connecting pipe; The storage outlet of the storage device 3 is connected to the granulation feed port of the granulator 4 through the second screw conveyor 8, and the storage outlet 3.3 of the storage device 3 is connected to the fuel inlet of the boiler 5 through a pipe...

Embodiment 2

[0095] A kind of excrement granular fertilizer production system, it comprises material preparation device 1, cooking device 2, storage fermentation device 3, granulator 4, boiler 5 and controller 6; Steam generation device selects boiler 5 for use in the present embodiment, cooking device 2 is set Above the storage device 3, a first temperature sensor 9 is provided in the cooking device 2, and a second temperature sensor 10 is provided in the storage device 3; The feed inlet 2.2 is connected by the first screw conveyor 7, the cooking outlet 2.5 of the cooking device 2 is connected with the fermentation feed inlet 3.2 of the fermentation device 3 through a connecting pipe, and a discharger 13 is arranged on the connecting pipe; The storage outlet of the storage device 3 is connected to the granulation feed port of the granulator 4 through the second screw conveyor 8, and the storage outlet 3.3 of the storage device 3 is connected to the fuel inlet of the boiler 5 through a pipe...

Embodiment 3

[0111] A kind of method that utilizes the excrement granular fertilizer production system described in embodiment 1 to produce feces granular fertilizer, it comprises the following steps successively: operation one: preparation; operation two: cooking; operation three: fermentation; operation four: granulation; wherein

[0112] Step 1: Prepare materials

[0113] Add the feces, dung and feces collected by the suction truck to the feces-water mixture, additives and water into the material preparation tank 1.1, turn on the material preparation agitator 1.5, and stir at a speed of 33r / min for 10min to obtain feces with a moisture content of 55%. The additives are fly ash and straw powder, and the particle size of the straw powder is <20 mesh.

[0114] Step 2: Cooking

[0115] Utilize the first screw conveyor 7 to transport the feces and water to the cooking tank 2.1, start the cooking agitator 2.7, stir at a speed of 20r / min, and feed steam to heat up and kill insects and eggs, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com