Method for extracting phycoerythrin with assistance of spray freeze dryer

A spray freeze-drying and phycoerythrin technology, applied in chemical instruments and methods, algae/moss peptides, peptide sources, etc., can solve the problems of long production cycle, high equipment requirements, high viscosity, shorten production cycle, reduce production Steps to overcome the effect of difficult dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for auxiliary extraction of phycoerythrin by a spray freeze dryer of this embodiment is characterized in that it comprises the following steps:

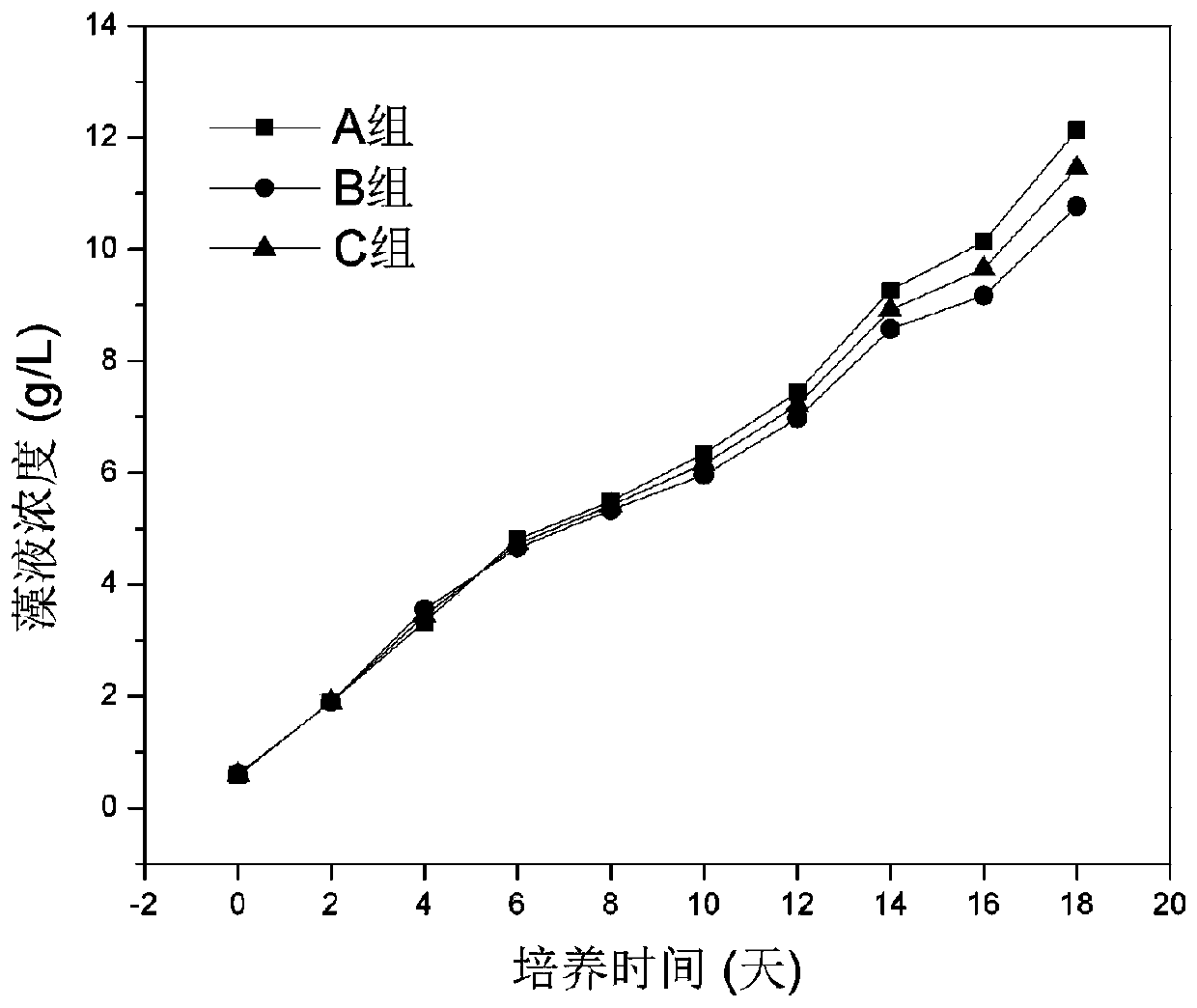

[0030] 1) Cultivation to obtain high-concentration algae liquid: cultivate Porphyridium in artificial seawater medium (ASW) for 10 days to a high-concentration period (biomass 8.04g / L).

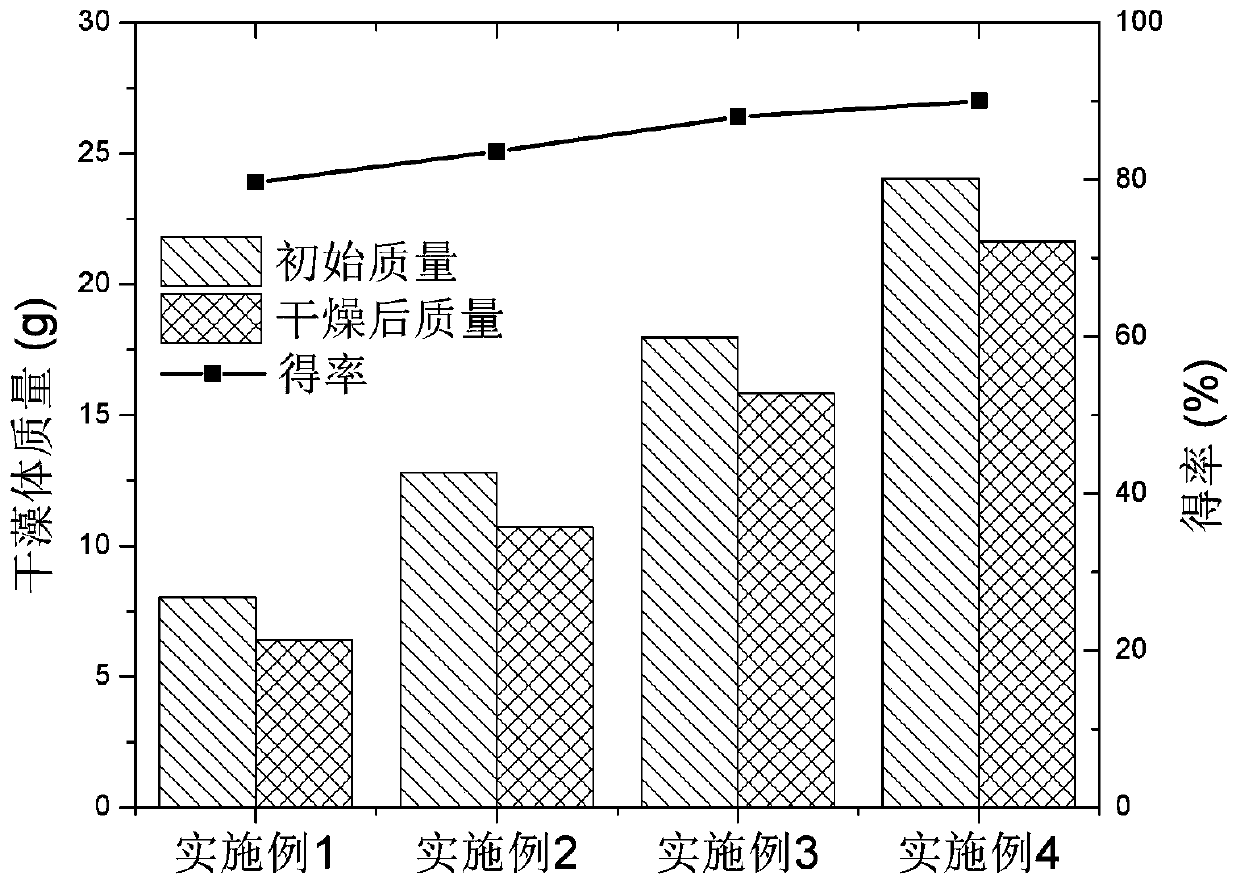

[0031] 2) Using spray freeze-drying to prepare dry Porphyridium algae powder: Use a spray freeze dryer with a volume of 1000 mL of Porphyridium algae to make ultra-fine dry Porphyridium powder. The conditions for spray freeze-drying are: drying temperature: -5℃, the peristaltic pump speed is 11r / min, and the drying time is 2h. After drying, the dried powder is collected and passed through a 40-inch 0.45mm sieve to obtain superfine dried Porphyridium algae powder.

[0032] 3) Extraction and purification:

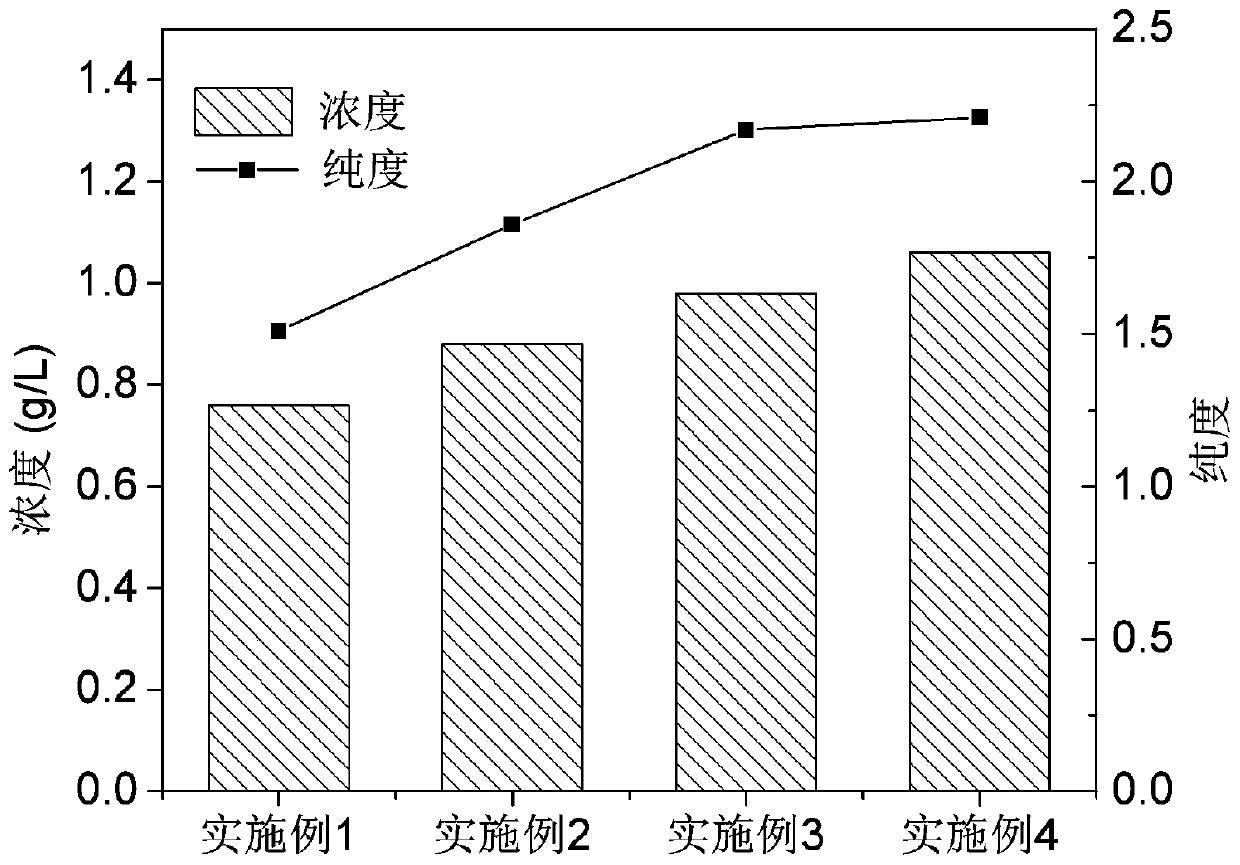

[0033] The first step: mix the dry algae powder and deionized water with a certain mass-volume ratio (1:3) using a mechanical stirring ...

Embodiment 2

[0038] The method for auxiliary extraction of phycoerythrin by a spray freeze dryer of this embodiment is characterized in that it comprises the following steps:

[0039] 1) Cultivation to obtain high-concentration algae liquid: cultivate Porphyridium in artificial seawater medium (ASW) for 12 days to a high-concentration period (biomass 10.86g / L).

[0040] 2) Using spray freeze-drying to prepare dry Porphyridium algae powder: Use a spray freeze dryer with a volume of 1300 mL of Porphyridium sp -8℃, the speed of the peristaltic pump is 14r / min, and the drying time is 3h. After drying, the dried powder is collected and passed through a 40-inch 0.45mm sieve to obtain superfine dried Porphyridium algae powder.

[0041] 3) Extraction and purification:

[0042] The first step: mix the dry algae powder and deionized water with a certain mass-to-volume ratio (1:5) using a mechanical stirring device, and the stirring speed is 500r / min.

[0043] The second step: the freeze-thaw method is used ...

Embodiment 3

[0047] The method for auxiliary extraction of phycoerythrin by a spray freeze dryer of this embodiment is characterized in that it comprises the following steps:

[0048] 1) Cultivation to obtain high-concentration algae liquid: cultivate Porphyridium in artificial seawater medium (ASW) for 14 days to a high-concentration period (biomass 11.24g / L).

[0049] 2) Using spray freeze-drying to prepare dry Porphyridium algae powder: Use a spray freeze dryer with a volume of 1600 mL of Porphyridium algae to make ultra-fine dry Porphyridium powder. The conditions for spray freeze drying are: drying temperature -12℃, the speed of the peristaltic pump is 16r / min, and the drying time is 4h. After drying, the dried powder is collected and passed through a 40-inch 0.45mm sieve to obtain ultra-fine dried Porphyridium algae powder.

[0050] 3) Extraction and purification:

[0051] The first step: mix the dry algae powder and deionized water with a certain mass-volume ratio (1:7) using a mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com