A kind of composite nano lubricating oil additive with self-healing function and preparation method thereof

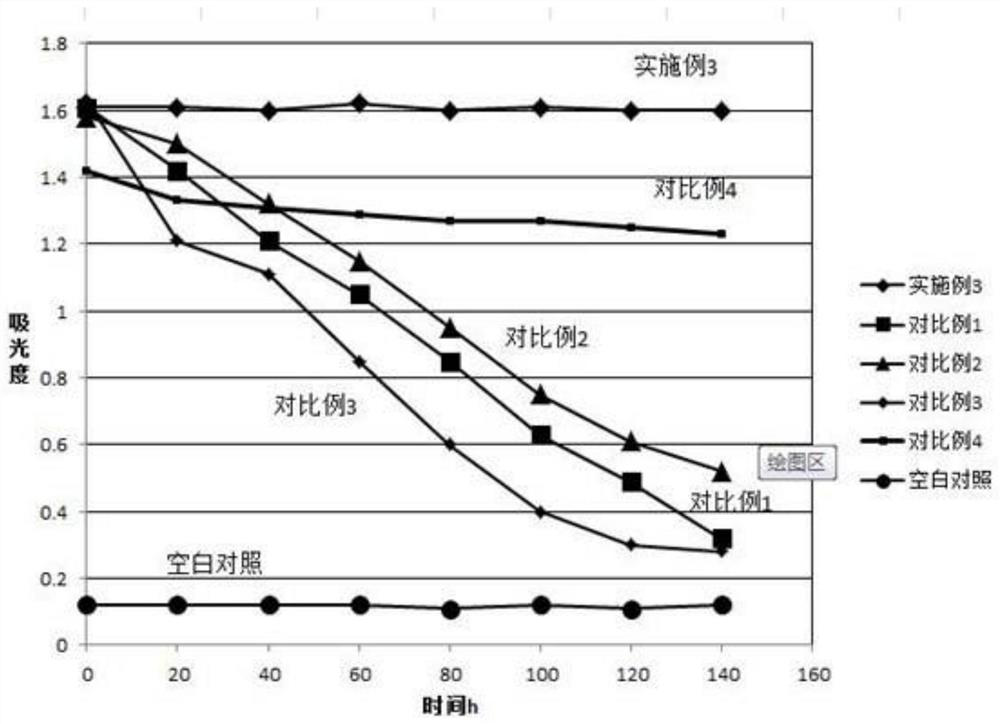

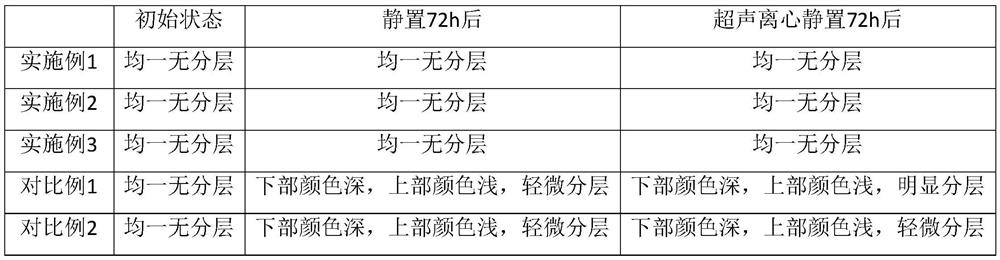

A lubricating oil additive and composite nanoparticle technology, which is applied in the field of lubricating oil, can solve problems such as easy agglomeration, single function, and poor dispersion effect of nanoparticle additives, so as to alleviate agglomeration, increase lubricating effect, and significantly reduce and antiwear effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A composite nano-lubricating oil additive with self-repairing function, the composition is as follows in parts by mass: 20 parts of modified composite nanoparticles, 10 parts of ultrafine mineral powder, 5 parts of sodium alkylbenzene sulfonate, and 3 parts of anti-wear agent and preservatives 3 parts.

[0031] The modified composite nanoparticles are prepared by the following method:

[0032] (1) Weigh copper chloride and sodium hydroxide respectively, and configure them into aqueous solutions with molar concentrations of 3mol / L and 3mol / L respectively, and gradually drop in hydrogen while stirring the copper chloride solution according to the volume ratio of 1:5 Sodium oxide solution to obtain a uniform copper hydroxide suspension;

[0033] (2) Use deionized water to wash the copper hydroxide suspension obtained in step (1) for 3-5 times, then add composite nanoparticles according to the solid-to-liquid ratio of 1g: 3ml, stir for 24 hours to obtain the mixed solution...

Embodiment 2

[0048] A composite nano-lubricating oil additive with self-repairing function, the composition is as follows in parts by mass: 25 parts of modified composite nanoparticles, 15 parts of ultrafine mineral powder, 8 parts of sodium alkylbenzene sulfonate, and 5 parts of anti-wear agent and preservatives 4 parts.

[0049] The modified composite nanoparticles are prepared by the following method:

[0050] (1) Weigh copper chloride and sodium hydroxide respectively, and configure them into aqueous solutions with molar concentrations of 3mol / L and 3mol / L respectively, and gradually drop in hydrogen while stirring the copper chloride solution according to the volume ratio of 1:5 Sodium oxide solution to obtain a uniform copper hydroxide suspension;

[0051] (2) Use deionized water to wash the copper hydroxide suspension obtained in step (1) for 3-5 times, then add composite nanoparticles according to the solid-to-liquid ratio of 1g: 3ml, stir for 24 hours to obtain the mixed solution...

Embodiment 3

[0066] A composite nano-lubricating oil additive with self-repairing function, the composition is as follows in parts by mass: 30 parts of modified composite nanoparticles, 20 parts of ultrafine mineral powder, 10 parts of sodium alkylbenzene sulfonate, and 6 parts of anti-wear agent And 5 parts of preservatives.

[0067] The modified composite nanoparticles are prepared by the following method:

[0068] (1) Weigh copper chloride and sodium hydroxide respectively, and configure them into aqueous solutions with molar concentrations of 3mol / L and 3mol / L respectively, and gradually drop in hydrogen while stirring the copper chloride solution according to the volume ratio of 1:5 Sodium oxide solution to obtain a uniform copper hydroxide suspension;

[0069] (2) Use deionized water to wash the copper hydroxide suspension obtained in step (1) for 3-5 times, then add composite nanoparticles according to the solid-to-liquid ratio of 1g: 3ml, stir for 24 hours to obtain the mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com