Nitrogen-doped carbon nanotube oxygen-reduction electrocatalyst and preparation method thereof

A nitrogen-doped carbon and electrocatalyst technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of high catalyst preparation cost, complicated process, and expensive price, and achieve mild preparation conditions, simple preparation, and low surface tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

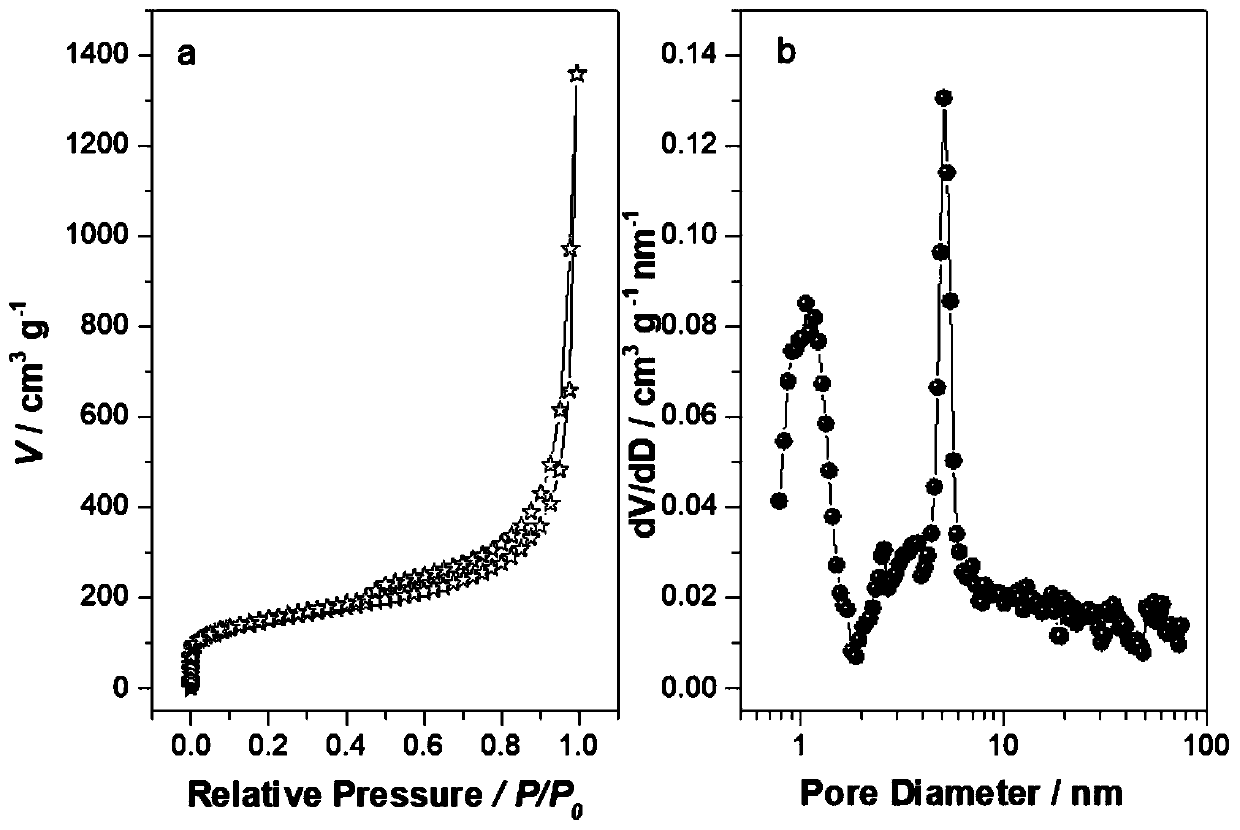

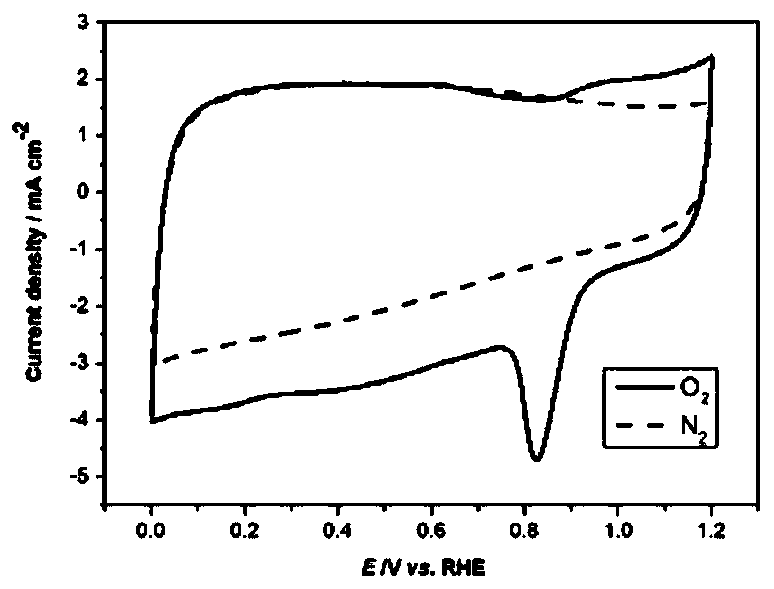

[0028] A preparation method of nitrogen-doped carbon nanotube oxygen reduction electrocatalyst, comprising the following steps:

[0029] 1) Calcining 10g of melamine at 550°C for 4h in an air atmosphere in a tube furnace to obtain g-C 3 N 4 powder;

[0030] 2) Put 1 g of g-C in a single-necked flask 3 N 4 Add the powder into 80mL methanol solution, and disperse evenly by ultrasonic;

[0031] 3) Add 80 mL of methanol solution of ferric ammonium citrate (0.05 mmol) and zinc nitrate (2.5 mmol) into the above flask, ultrasonically or stir evenly, and then put it on a magnetic stirrer to react for 6 h;

[0032] 4) Add 80 mL of 2-methylimidazole solution (6 mmol) to the above-mentioned flasks respectively; stir well to obtain a homogeneous feed solution, then place it on a magnetic stirrer, react for 24 hours, and centrifugally dry to obtain a powder;

[0033] 5) The powder sample was heat-treated at 900° C. for 2 h under an inert atmosphere, then acid-treated, washed with wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com