Composite vehicle air conditioning filter core and preparation method thereof

A composite material, vehicle-mounted air conditioner technology, applied in the field of air conditioner filter elements, can solve the problems of limited dust holding capacity, short service life and general filtering effect of the filter element, achieve good adsorption and ion exchange capacity, reduce stacking and agglomeration, The effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

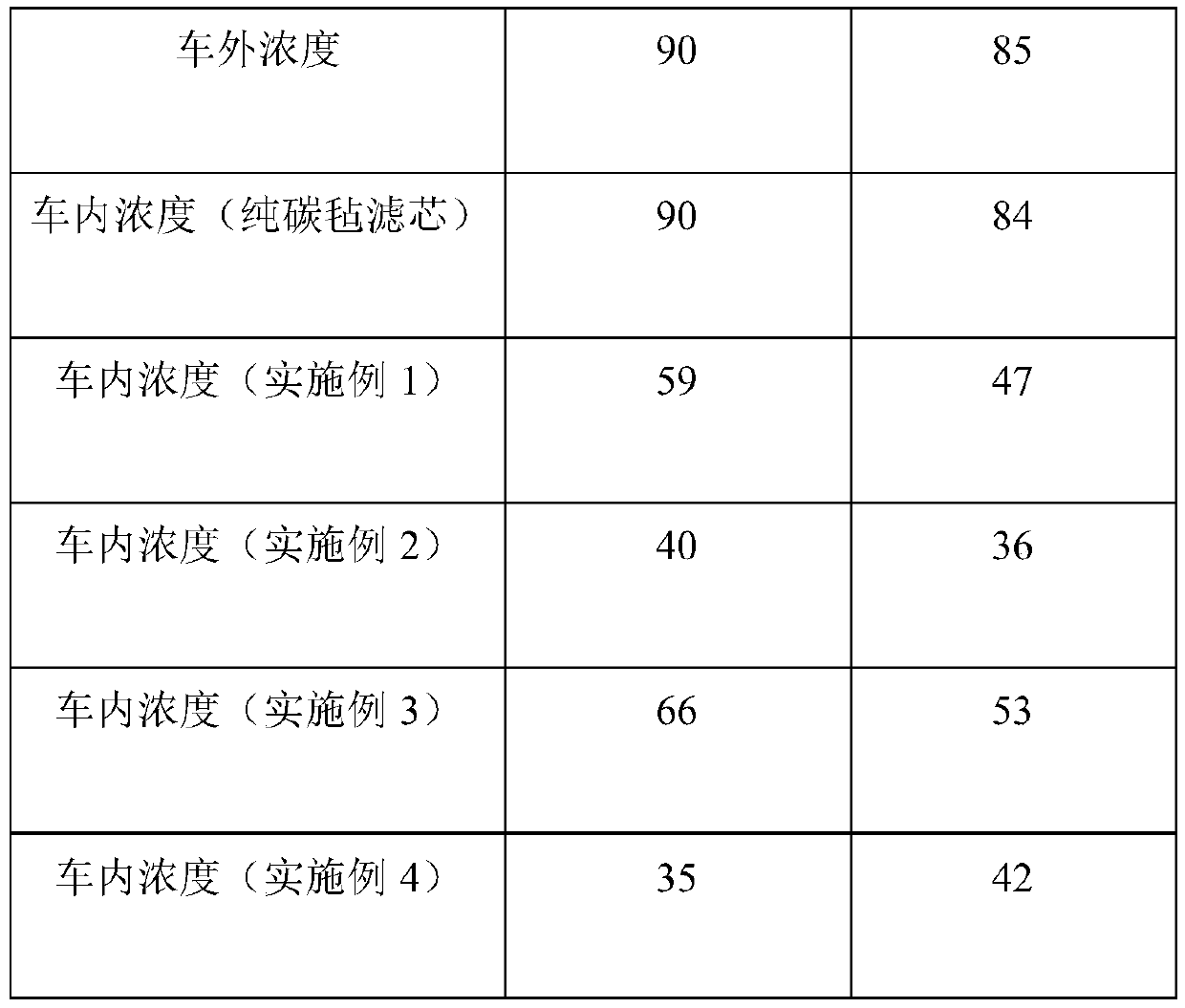

Embodiment 1

[0022] A composite vehicle-mounted air-conditioning filter element according to the embodiment of the present invention is prepared according to the following steps:

[0023] Step 1): Weigh 0.2mol of magnesium chloride and 0.1mol of ferric chloride and dissolve them in 100mL of deionized water, stir to dissolve completely, then quickly add 1mol of NaOH, 100W ultrasonic for 30min, and transfer the mixture into the reaction kettle after ultrasonic , and reacted at 120°C for 24 hours. After the reaction solution was centrifuged, washed three times with deionized water and ethanol, and dried and ground, the product obtained was hydrotalcite LDH; step 2): Weigh 0.6g LDH and 3g melamine and mix thoroughly, set In a muffle furnace, it is calcined at 300°C for 6 hours in a nitrogen atmosphere, and then dispersed in water. The resulting product is LDH / g-C 3 N 4 dispersion; step 3): carbon fiber felt in H 2 SO 4 Soak in the solution for 1h, then wash with ethanol and water in turn, a...

Embodiment 2

[0025] A composite vehicle-mounted air-conditioning filter element according to the embodiment of the present invention is prepared according to the following steps:

[0026] Step 1): Weigh 0.3mol of magnesium nitrate and 0.1mol of ferric nitrate and dissolve them in 100mL of deionized water, stir to dissolve completely, then quickly add 0.8mol of NaOH, 150W ultrasonic for 30min, and transfer the mixture into the reaction kettle after ultrasonic , react at 120°C for 24 hours, centrifuge the reaction solution, wash three times with deionized water and ethanol, dry and grind, and the product obtained is hydrotalcite LDH; Step 2): Weigh 0.8g LDH and 3g melamine and mix thoroughly, Put it in a muffle furnace, bake it at 300°C for 6 hours in a nitrogen atmosphere, and then disperse it in water. The product obtained is LDH / g-C3 N 4 dispersion; step 3): carbon fiber felt in H 2 SO 4 Soak in the solution for 1h, then wash with ethanol and water in turn, and then dry; step 4): put th...

Embodiment 3

[0028] A composite vehicle-mounted air-conditioning filter element according to the embodiment of the present invention is prepared according to the following steps:

[0029] Step 1): Weigh 0.04mol of magnesium sulfate and 0.01mol of ferric sulfate and dissolve them in 100mL of deionized water, stir to dissolve completely, then quickly add 0.12mol of NaOH, 60W ultrasonic for 30min, and transfer the mixture into the reaction kettle after ultrasonic reaction at 120°C for 24 hours, the reaction solution was centrifuged, washed three times with deionized water and ethanol, dried and ground, and the product obtained was hydrotalcite LDH; Step 2): Weigh 0.8g LDH and 2g melamine and mix thoroughly, Put it in a muffle furnace, bake it at 300°C for 6 hours in a nitrogen atmosphere, and then disperse it in water. The product obtained is LDH / g-C 3 N 4 dispersion; step 3): carbon fiber felt in H 2 SO 4 Soak in the solution for 1h, then wash with ethanol and water in turn, and then dry;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com