Method for preparing carbon quantum dots from lignin, and product

A technology of carbon quantum dots and lignin, which is applied in the field of carbon quantum dot preparation, can solve the problems of reaction equipment with pressure resistance requirements, increased equipment investment, and high production costs, so as to improve the dissolution and dispersion rate, increase the yield, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

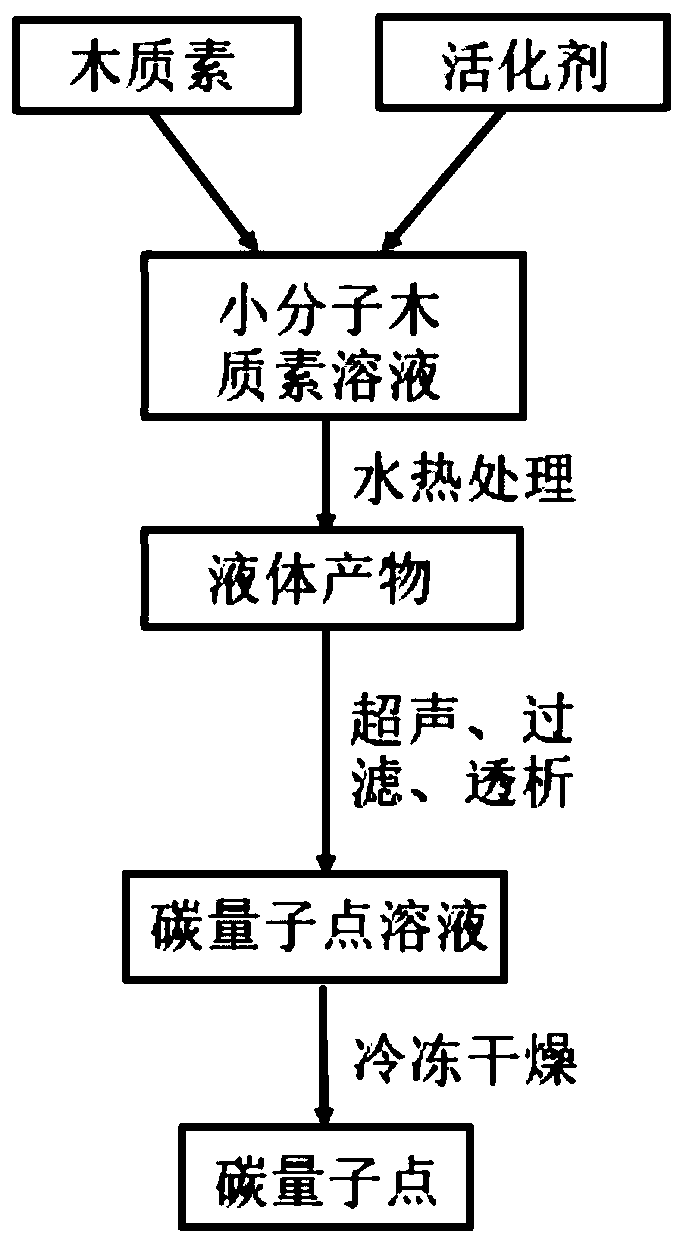

Method used

Image

Examples

Embodiment 1

[0036] (a) Weigh 100 mg of lignin and place it in 100 mL of ultrapure water to obtain a lignin solution with a concentration of 1 mg / mL, then put the lignin solution into an ultrasonic wave with a power of 60 W and a frequency of 40 Hz for 10 minutes to make it completely Dissolve, then add 10mL hydrogen peroxide at a volume ratio of 1:10, place the lignin solution containing hydrogen peroxide in an ultrasonic generator with a power of 60w and a frequency of 40 Hz for 20 minutes, and use ultrasound to decompose the lignin and completely dissolved to obtain a small molecule lignin solution;

[0037] (b) Transfer the small molecule lignin solution to a hydrothermal reaction kettle with a polytetrafluoroethylene liner, ensure that the stirring rate is 200r / min, conduct a hydrothermal treatment at 200°C for 12 hours, and cool to room temperature after the reaction is completed to obtain dark brown liquid product;

[0038] (c) The obtained liquid product is transferred to a power ...

Embodiment 2

[0043] (a) Weigh 2g of lignin and place it in 100mL of ultrapure water to obtain a lignin solution with a concentration of 20mg / mL, then put the lignin solution into an ultrasonic wave with a power of 60w and a frequency of 40 Hz for 30 minutes to make it completely Dissolve, then add 25mL hydrogen peroxide at a volume ratio of 1:4, place the lignin solution containing hydrogen peroxide in an ultrasonic generator with a power of 60w and a frequency of 40 Hz for 30 minutes, and decompose the lignin by ultrasonic and completely dissolved to obtain a small molecule lignin solution;

[0044] (b) Transfer the small molecule lignin solution to a hydrothermal reaction kettle with a polytetrafluoroethylene liner, ensure that the stirring rate is 300r / min, conduct hydrothermal treatment at 250°C for 24 hours, and cool to room temperature after the reaction is completed to obtain dark brown liquid product;

[0045] (c) transfer the obtained liquid product to a power of 60w, a frequency...

Embodiment 3

[0048] (a) Weigh 500 mg of lignin and place it in 100 mL of ultrapure water to obtain a lignin solution with a concentration of 5 mg / mL, then put the lignin solution into an ultrasonic wave with a power of 60 W and a frequency of 40 Hz for 10 minutes to make it completely Dissolve, then add 5mL of concentrated sulfuric acid according to the volume ratio of 1:20, place the lignin solution containing concentrated sulfuric acid in an ultrasonic generator with a power of 60w and a frequency of 40 Hz for 10 minutes, and use ultrasound to decompose the lignin and completely Dissolving to obtain a small molecule lignin solution;

[0049] (b) Transfer the small molecule lignin solution to a hydrothermal reaction kettle with a polytetrafluoroethylene liner, ensure that the stirring rate is 100r / min, conduct a hydrothermal treatment at 150°C for 2 hours, and cool to room temperature after the reaction is completed to obtain dark brown liquid product;

[0050] (c) The obtained liquid pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com