Green energy-saving Fe-ZSM-5 molecular sieve synthesis method

A fe-zsm-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of low synthesis efficiency, high autogenous pressure, complicated operation of post-processing methods, etc. problems, to achieve the effect of reducing energy consumption, shortening high-temperature crystallization time, and broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the synthesis of Fe-ZSM-5 molecular sieve:

[0026] (1) the reaction raw materials according to the molar ratio Na 2 SiO 3 •9H 2 O: SiO 2 : TPABr: NH 4 Cl: Fe(NO 3 ) 3 •9H 2 O: H 2 o 2 =0.088: 1: 0.16: 1.345: 0.04: 0.02 Weigh it and pour it into a mortar, and grind it by hand for 15~20 min until it is evenly mixed;

[0027] (2) The ground mixture was transferred to a polytetrafluoroethylene-lined autoclave, pretreated at 80 °C for 18 h at low temperature, and then crystallized at 180 °C for 24 h at high temperature;

[0028] (3) After the crystallization reaction, cool down to room temperature with running water, and then use deionized water and absolute ethanol to wash by centrifugation until the supernatant is clear, and dry at 110 °C for 150 min to obtain the molecular sieve powder;

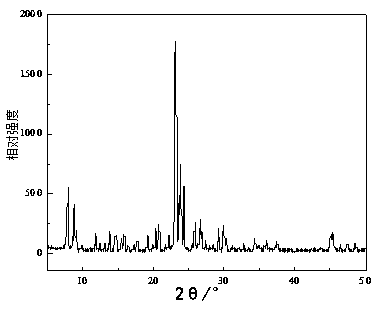

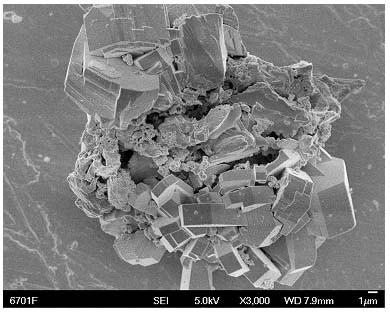

[0029] (4) The raw molecular sieve powder was calcined at 550 ℃ for 4 h to obtain Fe-ZSM-5 molecular sieve powder, which was detected by XRD with a relative crys...

Embodiment 2

[0030] Embodiment 2: the synthesis of Fe-ZSM-5 molecular sieve:

[0031] (1) the reaction raw materials according to the molar ratio Na 2 SiO 3 •9H 2 O: SiO 2 : TPABr: NH 4 Cl: Fe(NO 3 ) 3 •9H 2 O: H 2 o 2 =0.088: 1: 0.16: 1.345: 0.04: 0.048 Weigh it and pour it into a mortar, and grind it by hand for 15~20 min until it is evenly mixed;

[0032] (2) The ground mixture was transferred to a polytetrafluoroethylene-lined autoclave, pretreated at 80 °C for 18 h at low temperature, and then crystallized at 180 °C for 24 h at high temperature;

[0033] (3) After the crystallization reaction, cool down to room temperature with running water, and then use deionized water and absolute ethanol to wash by centrifugation until the supernatant is clear, and dry at 110 °C for 150 min to obtain the molecular sieve powder;

[0034](4) The raw molecular sieve powder was calcined at 550 ℃ for 4 h to obtain Fe-ZSM-5 molecular sieve powder, which was detected by XRD with a relative crys...

Embodiment 3

[0035] Embodiment 3: the synthesis of Fe-ZSM-5 molecular sieve:

[0036] (1) the reaction raw materials according to the molar ratio Na 2 SiO 3 •9H 2 O: SiO 2 : TPABr: NH 4 Cl: Fe(NO 3 ) 3 •9H 2 O: H 2 o 2 =0.088: 1: 0.16: 1.345: 0.04: 0.08 Weigh it and pour it into a mortar, and grind it by hand for 15~20 min until it is evenly mixed;

[0037] (2) The ground mixture was transferred to a polytetrafluoroethylene-lined autoclave, pretreated at 80 °C for 18 h at low temperature, and then crystallized at 180 °C for 24 h at high temperature;

[0038] (3) After the crystallization reaction, cool down to room temperature with running water, and then use deionized water and absolute ethanol to wash by centrifugation until the supernatant is clear, and dry at 110 °C for 150 min to obtain the molecular sieve powder;

[0039] (4) The raw molecular sieve powder was calcined at 550 ℃ for 4 h to obtain Fe-ZSM-5 molecular sieve powder, which was detected by XRD with a relative crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com