Terminated short fluorocarbon chain hyperbranched nano hybrid leather super-hydrophobic coating material and preparation method thereof

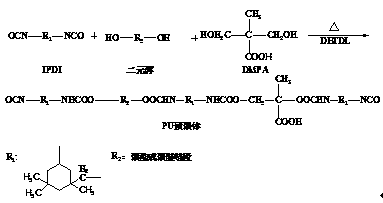

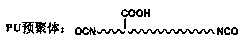

A technology with short fluorocarbon chains and terminal hydroxyl hyperbranching, which is applied in leather surface treatment, polyurea/polyurethane coating, small raw leather/big raw leather/leather/fur treatment, etc., and can solve the problem of high water-based polyurethane water resistance and easy pollution of the environment Cost and other issues, to achieve the effect of improving water resistance, improving hydrophobicity, and reducing the amount of introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

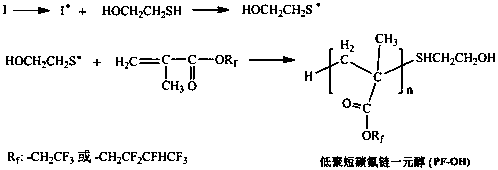

[0034]Add 0.78g of mercaptoethanol (β-ME) and 12.50g of hexafluorobutyl methacrylate into a four-neck flask with a condenser tube, and add 30g of ethyl acetate to it, then feed nitrogen into the flask for 10min, Bleed the air out of the system. Add dropwise 0.16g azobisisobutyronitrile (AIBN) that is dissolved in 20g ethyl acetate afterwards, continue feeding nitrogen under the condition of 70 ℃ and start stirring reaction 15h, rotary evaporation removes ethyl acetate afterwards, then use n-heptyl Wash with alkane to remove unreacted monomers, and finally vacuum-dry to remove n-heptane to obtain light yellow viscous oligomeric short fluorocarbon chain monohydric alcohol (PF-OH). Accurately weigh 3.00g of nano-SiO2 and disperse in acetone, and disperse evenly in an ultrasonic disperser at room temperature; then weigh 0.55g of KH-550 and add it to the dispersion, continue to disperse evenly by ultrasonic, and then transfer it to a three-necked flask. Stir the reaction at C for ...

Embodiment 2

[0036] Add 0.78g of mercaptoethanol (β-ME) and 16.80g of trifluoroethyl methacrylate into a four-necked flask with a condenser tube, and add 40g of ethyl acetate to it, then feed nitrogen into the flask for 10min, Bleed the air out of the system. Add dropwise 0.16g azobisisobutyronitrile (AIBN) that is dissolved in 20g ethyl acetate afterwards, continue feeding nitrogen under the condition of 70 ℃ and start stirring reaction 15h, rotary evaporation removes ethyl acetate afterwards, then use n-heptyl Wash with alkane to remove unreacted monomers, and finally vacuum-dry to remove n-heptane to obtain light yellow viscous oligomeric short fluorocarbon chain monohydric alcohol (PF-OH). Accurately weigh 3.10g of nano-SiO2 and disperse in acetone, and disperse evenly in an ultrasonic disperser at room temperature; then weigh 0.45g of aminopropyltrimethoxysilane and add it to the dispersion, continue to disperse evenly with ultrasonic, and then transfer it to a three-necked flask , s...

Embodiment 3

[0038] Add 1.56g of mercaptoethanol (β-ME) and 37.50g of hexafluorobutyl methacrylate into a four-necked flask with a condenser tube, and add 120g of ethyl acetate to it, then feed nitrogen into the flask for 10min, Bleed the air out of the system. Add dropwise 0.16g azobisisobutyronitrile (AIBN) that is dissolved in 20g ethyl acetate afterwards, continue feeding nitrogen under the condition of 70 ℃ and start stirring reaction 15h, rotary evaporation removes ethyl acetate afterwards, then use n-heptyl Wash with alkane to remove unreacted monomers, and finally vacuum-dry to remove n-heptane to obtain light yellow viscous oligomeric short fluorocarbon chain monohydric alcohol (PF-OH). Accurately weigh 5.80g of nano-SiO2 and disperse in acetone, and disperse evenly in an ultrasonic disperser at room temperature; then weigh 1.11g of KH-550 and add it to the dispersion, continue to disperse evenly by ultrasonic, and then transfer it to a three-necked flask. The reaction was stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com