A kind of medium manganese ultra-high strength steel and preparation method thereof

A technology of ultra-high-strength steel and preparation steps, applied in the field of advanced ultra-high-strength steel, can solve the problems of improving the production difficulty of Q&P steel, and achieve the effects of facilitating the diffusion of elements, simple composition, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

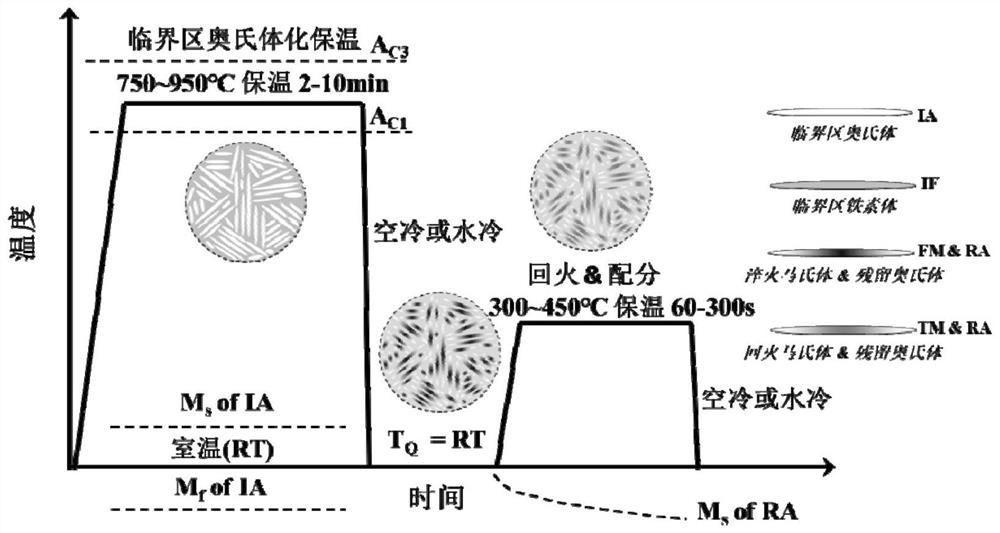

[0038] The second aspect of the present invention provides the preparation method of the above-mentioned medium manganese ultra-high strength steel, the schematic diagram of the preparation process is as follows figure 1 As shown, specifically, the casting slab of medium manganese ultra-high-strength steel satisfying the chemical composition is subjected to the following preparation steps:

[0039] (1) The casting slab is kept in a heating furnace at 1180-1230° C. for 1-2 hours for uniform austenitization.

[0040] (2) The cast slab of the step (1) is subjected to two passes of rough rolling and multi-pass finish rolling, and the finish rolling temperature is 850-950° C., then water-cooled or air-cooled to room temperature to obtain a slab with a thickness of 2-8 mm. Hot rolled steel strip.

[0041] (3) heating the hot-rolled steel strip of the step (2) to the austenitizing temperature T in the critical zone IA = 750-950°C heat preservation for 2-10min, then water-cooled or ...

Embodiment 1

[0045] The chemical composition of this embodiment is 0.34% C, 3.95% Mn, 1.08% Al, 1.54% Si, 0.006% P, 0.014% S in terms of mass percentage, and the rest is Fe and unavoidable impurity elements.

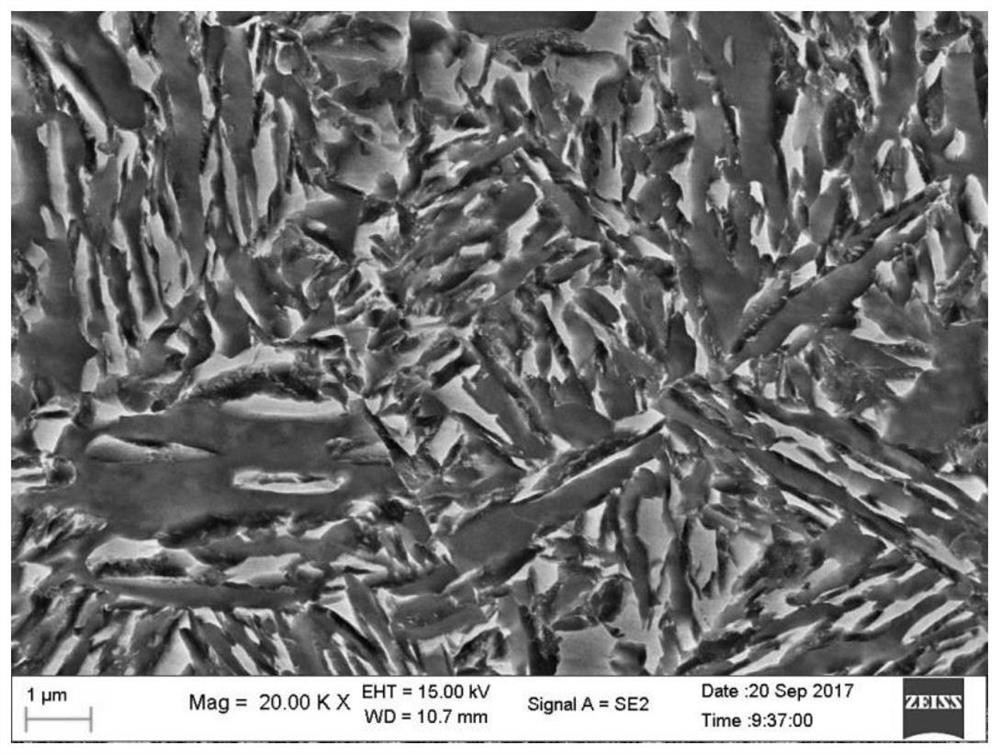

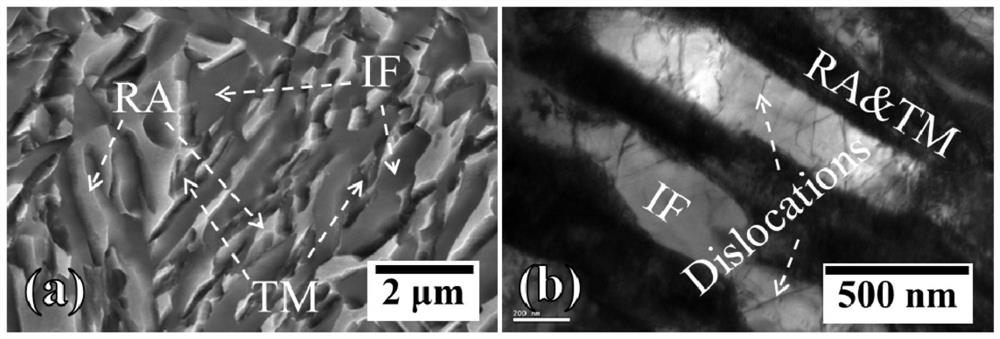

[0046] The preparation process is as follows: heat the slab with the above composition in a heating furnace at 1200°C for 1.5h, and after uniform austenitization, carry out two passes of rough rolling, multi-pass finish rolling, and finish rolling at a temperature of 942°C, air cooling After reaching room temperature, a hot-rolled steel strip with a thickness of 3 mm is obtained, and the structure of the hot-rolled steel strip is a full martensitic structure. The hot-rolled steel strips are respectively heated to the austenitizing temperature T in the critical zone in an ordinary muffle furnace IA = 800°C, 830°C, holding time 4min, water cooling to room temperature, obtained quenched steel strip with microstructure of lath morphology critical zone ferrite (IF), quenched martensite (F...

Embodiment 2

[0049] The chemical composition of this embodiment is 0.33% C, 3.86% Mn, 1.85% Al, 1.55% Si, 0.006% P, 0.015% S in terms of mass percentage, and the rest is Fe and unavoidable impurity elements.

[0050] The preparation process of this example is basically the same as that of Example 1, except that the finish rolling temperature is 947°C, the thickness of the hot-rolled steel strip is 4mm, and the microstructure of the hot-rolled steel strip is 2% ferrite by volume fraction. The martensitic matrix organization of the organization. Critical zone austenitization T IA The temperature was 825°C, 850°C, and 900°C respectively, and the holding time was 5.5 minutes. put it to T TP = 450° C. in a muffle furnace for 250 s and tempering, the medium manganese ultra-high strength steel strip of this embodiment was obtained, and its corresponding mechanical properties are shown in Table 1. Among them, T IA =825°C for 5.5 minutes, T TP = 450 ℃ heat preservation 250s steel strip, its ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com