Soft smooth grafting-modified silk and preparation method thereof and grease emulsion

A graft modification, silk technology, applied in textiles and papermaking, improved hand-feeling fibers, fiber processing and other directions, can solve problems such as inability to industrialize applications, and achieve the effects of long-lasting treatment effect, simple process method and soft hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

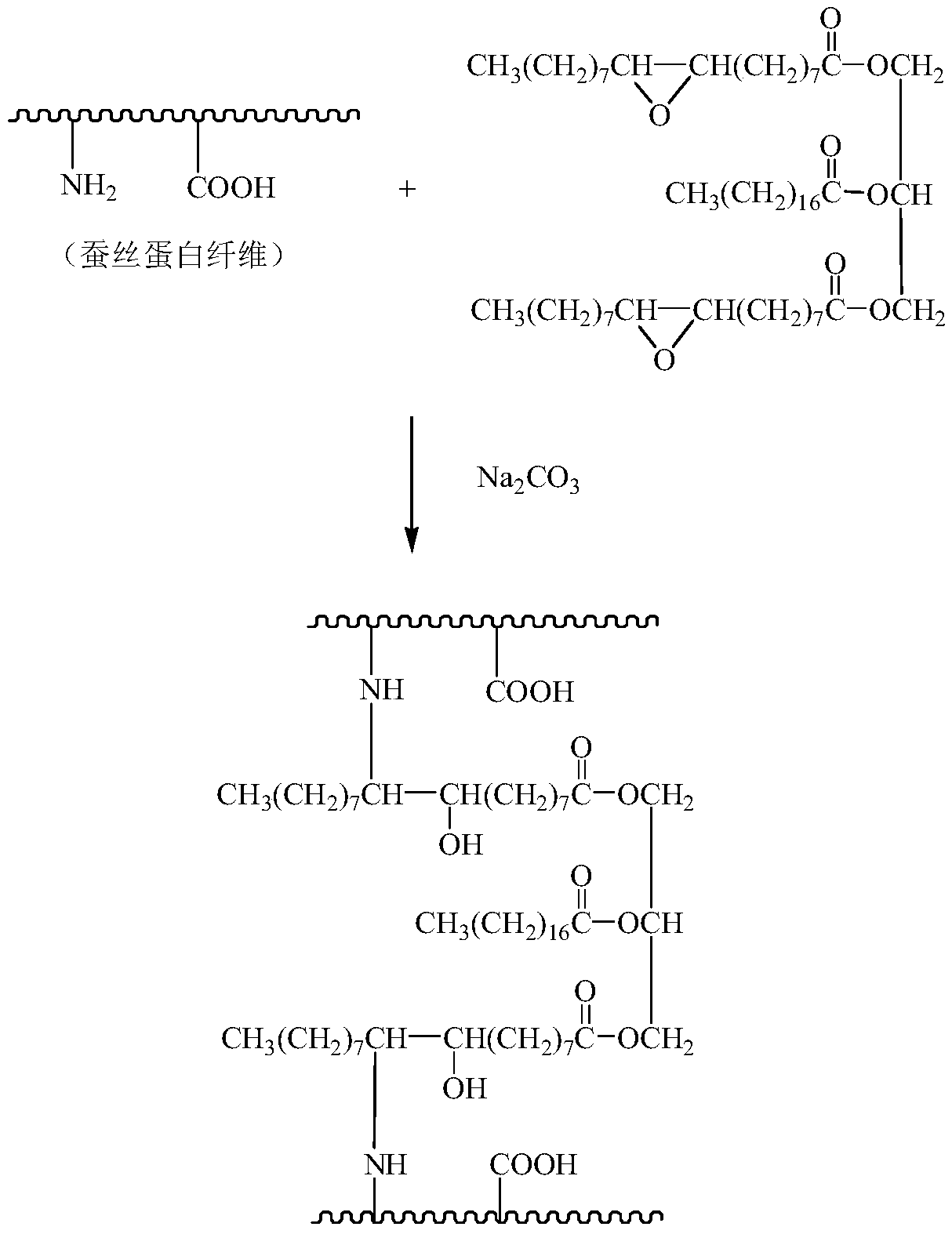

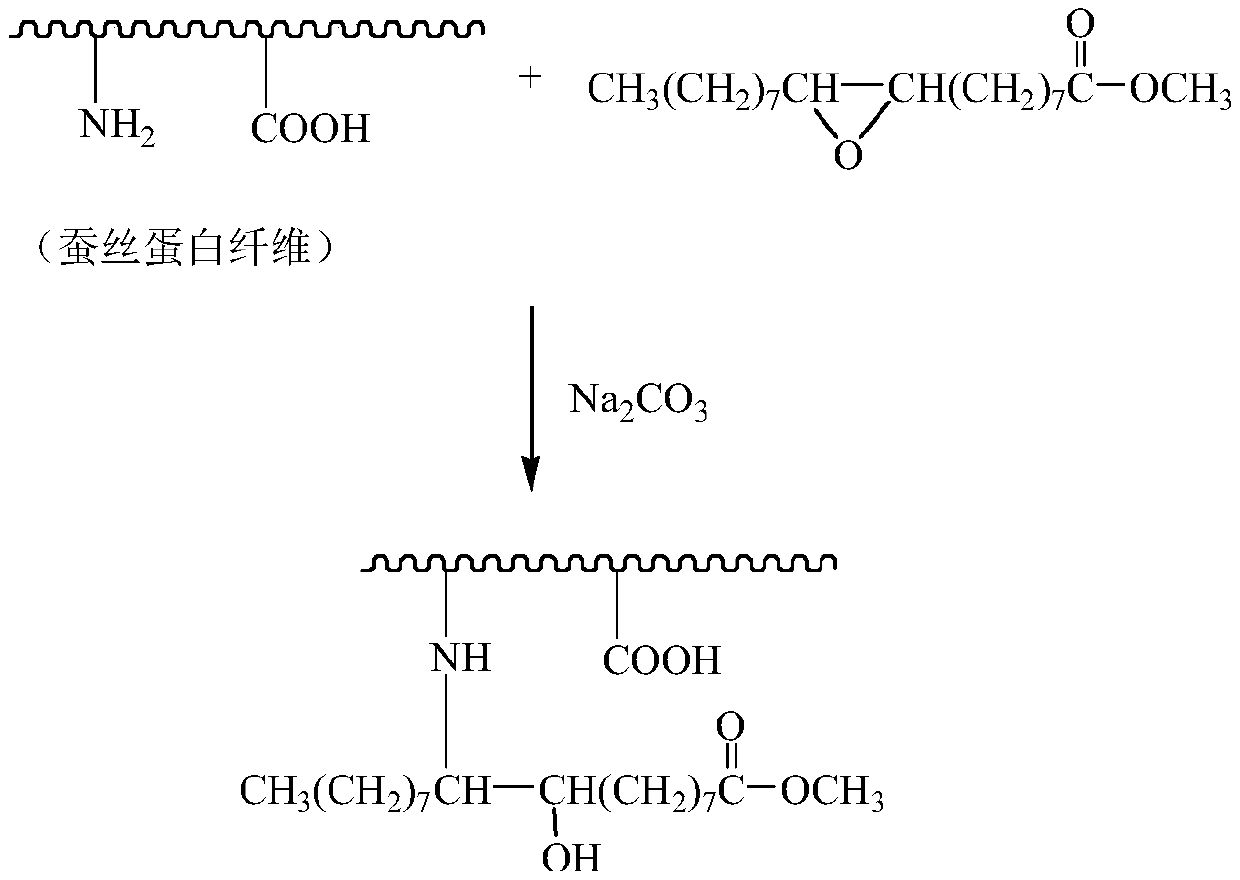

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of epoxidized soybean oil emulsion

[0044] Put 70 grams of epoxidized soybean oil, 15 grams of OS-15 and 5 grams of C16-18 mixed fatty alcohol into the emulsification pot, heat to 70°C, stir for 15 minutes, and slowly add 200 grams of 75°C hot water, keep warm and stir for 35 minutes, cool down to 40°C and discharge for later use.

[0045] (2) Put 8 times the mass of silk into water at 22°C, adjust the pH of the bath solution to 3.5 with formic acid, and soak for 1 hour.

[0046] (3) Dehydrate the fully soaked silk, put it into the epoxidized soybean oil emulsion with 1 times the mass of silk, and add 0.2% JFC (in bath liquid mass) and 0.2% baking soda (in bath mass). liquid quality meter), soak for 1h, then adjust and stabilize the pH value of the bath solution at 9.0 with 15% soda ash solution of mass concentration, and raise the temperature of the bath solution to 80°C and keep it for 4h.

[0047] (4) After de-drying the silk, stack it at 20°C for ...

Embodiment 2

[0050] (1) Preparation of epoxidized soybean oil emulsion

[0051] Put 80 grams of epoxidized soybean oil, 20 grams of OS-20 and 4 grams of C16-18 mixed fatty alcohol into the emulsification pot, heat to 75 ° C, stir for 20 minutes, and slowly add 250 grams of 80°C hot water, keep warm and stir for 60 minutes, cool down to 45°C and discharge for later use.

[0052] (2) Put 10 times the mass of silk into water at 30° C., adjust the pH of the bath solution to 4.5 with acetic acid, and soak for 1.5 hours.

[0053] (3) Dehydrate the fully soaked silk, put it into the epoxidized soybean oil emulsion of 2 times the quality, and add 0.25% JFC (based on the mass of the bath liquid) and 0.2% baking soda (based on the mass of the bath liquid) mass meter), soak for 2 hours, then adjust and stabilize the pH value of the bath solution at 8.5 with 10% soda ash solution of mass concentration, and raise the temperature of the bath solution to 70° C. and keep it for 2 hours.

[0054] (4) Aft...

Embodiment 3

[0057] (1) Preparation of epoxidized soybean oil fatty acid methyl ester emulsion

[0058] Put 75 grams of epoxidized soybean oil fatty acid methyl ester, 25 grams of OS-15 and 2 grams of stearic acid into the emulsification pot, heat to 80°C, stir for 30 minutes, and slowly add 300 grams of 70 ℃ hot water, keep warm and stir for 45 minutes, cool down to 35 ℃ and discharge for later use.

[0059] (2) Put 9 times the mass of silk into water at 40° C., adjust the pH of the bath solution to 5.5 with lactic acid, and soak for 2 hours.

[0060] (3) Dehydrate the completely soaked silk, put it into the epoxidized soybean oil fatty acid methyl ester emulsion of 6 times the quality, and add JFC0.2% (in bath liquid mass) and baking soda 0.2% ( Based on the mass of the bath liquid), soak for 1.5 h, then adjust and stabilize the pH value of the bath liquid at 8.0 with a 20% soda ash solution of mass concentration, and raise the temperature of the bath liquid to 60° C. and keep it for 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com