A kind of porous gan conductive dbr and preparation method thereof

A porosity and electrochemical technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low repetition rate, harsh conditions, poor conductivity of AlGaN materials, and achieve simple preparation methods, adjustable center wavelength, high The effect of reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

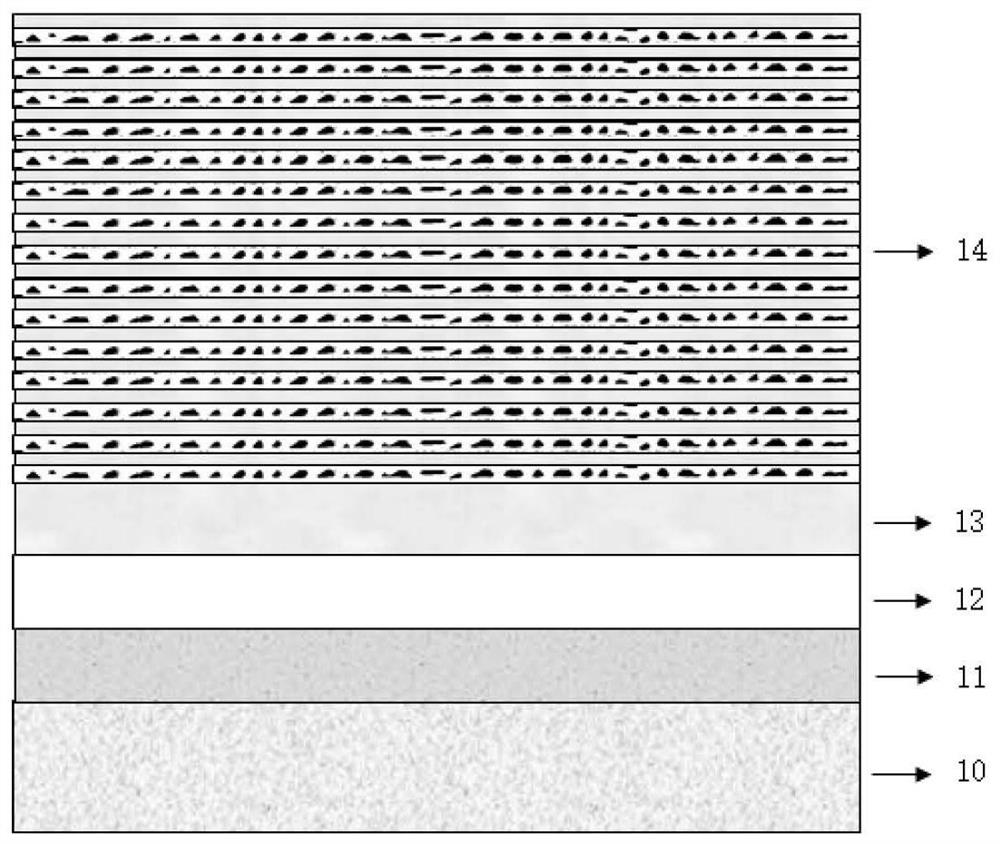

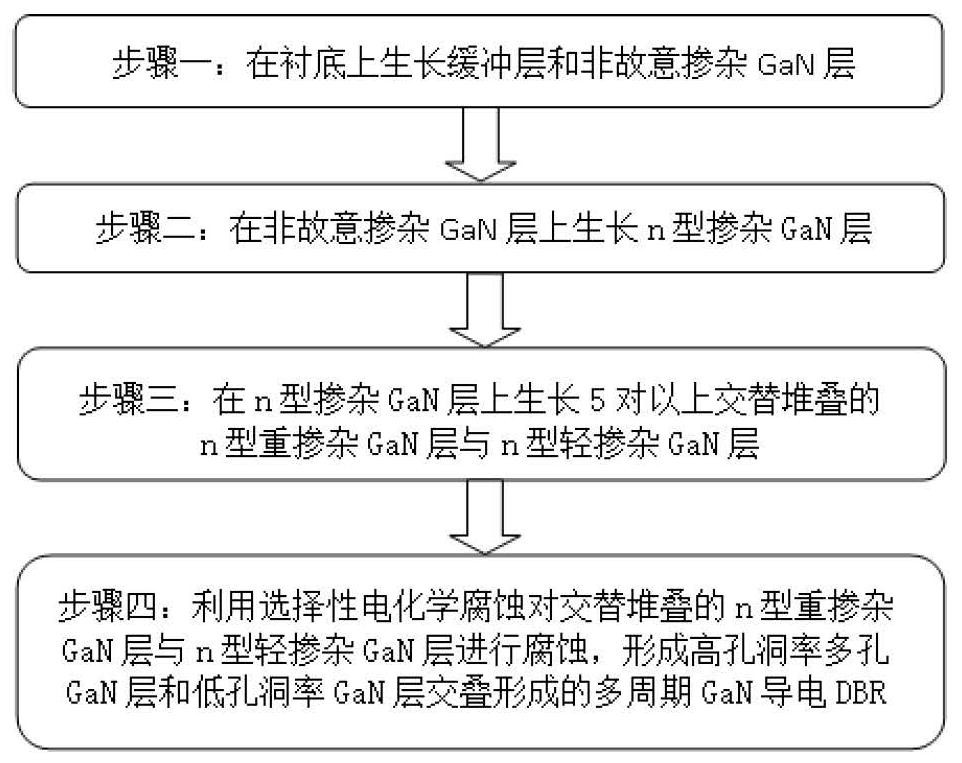

[0042] A porous GaN conductive DBR, such as figure 1 As shown, it includes a substrate 10, a buffer layer 11, an unintentionally doped GaN layer 12, an n-type intentionally doped gallium nitride layer 13 and a porous GaN conductive DBR layer 14 grown sequentially from bottom to top;

[0043]The porous GaN conductive DBR layer 14 is formed by alternately stacking 15 pairs of high-porosity porous GaN layers and low-porosity porous GaN layers, the porosity of the high-porosity porous GaN layer is 52%, and the porosity of the low-porosity porous GaN layer is 0 (i.e. no holes).

Embodiment 2

[0045] A porous GaN conductive DBR, the structure is as shown in embodiment 1, the difference is that the dopant of the n-type doped GaN layer 13 is silicon, and the doping concentration is 3×10 18 cm -3 .

Embodiment 3

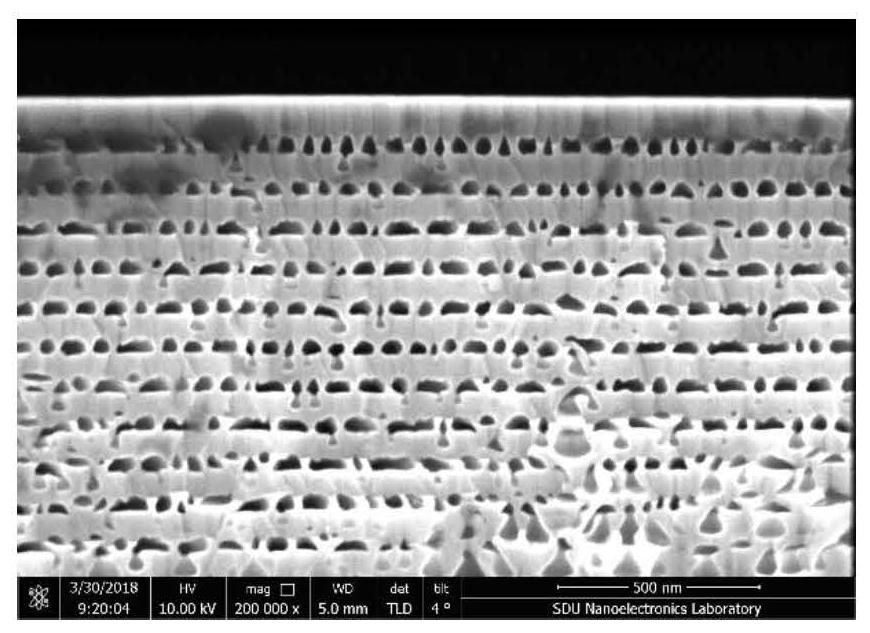

[0047] A porous GaN conductive DBR, the structure is as shown in Example 1, the difference is that the high-porosity porous GaN layer and the low-porosity porous GaN layer are alternately stacked n-type heavily doped GaN by electrochemical corrosion respectively. Layer and n-type lightly doped GaN layer are etched, the dopant of n-type lightly doped GaN layer and n-type heavily doped GaN layer is silicon, the higher the doping concentration, the higher the porosity formed, as image 3 As shown, it is a cross-sectional scanning electron microscope schematic diagram of a porous GaN conductive DBR structure at a magnification of 200,000 times. The holes formed by the n-type heavily doped GaN layer after electrochemical corrosion are relatively uniform, and the pore diameter is between 1 and 300 nm; while The uncorroded GaN layer is an n-type lightly doped GaN layer, and the two layers of materials have a refractive index difference due to the introduction of air holes, and are alt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com