Preparation method of composite microencapsulated anti-ultraviolet finishing agent

A compound microcapsule and anti-ultraviolet technology, which is applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of skin allergies, low absorption capacity of inorganic scattering agents, etc., and achieve good inhibition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

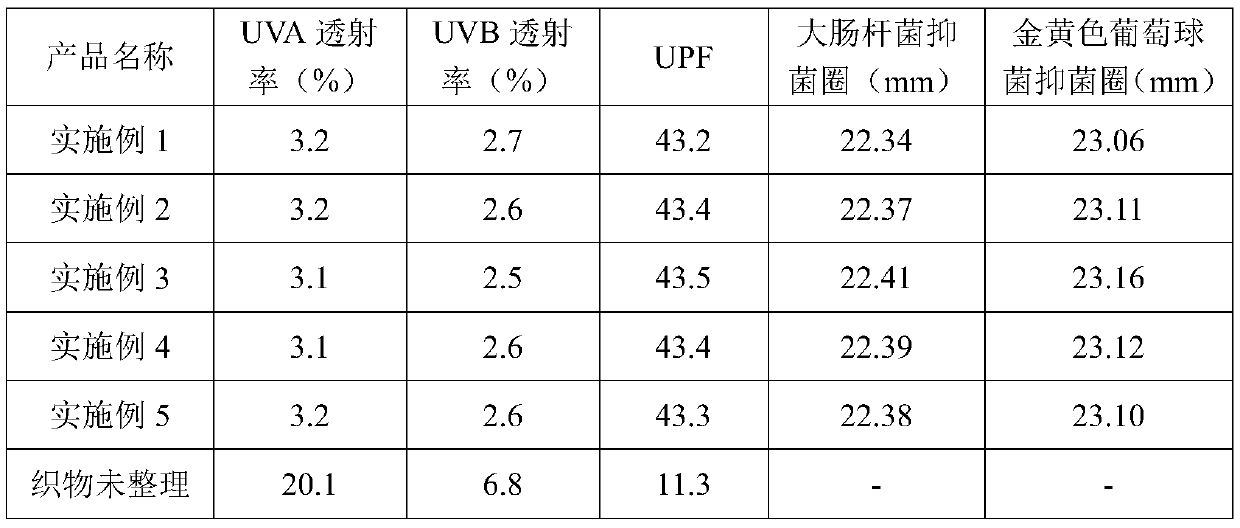

Examples

Embodiment 1

[0028] A preparation method of a composite microcapsule anti-ultraviolet finishing agent, the components are calculated in parts by weight, comprising the following steps:

[0029] (1) Collect walnut shells, pulverize after drying, add ethanol solution to extract for 40min, and collect the extract;

[0030] (2) Concentrate the extract to 1.5 times the weight of the walnut shell, refrigerate at low temperature for 12 hours, filter, adjust the pH value to 1.5, heat to 70°C, keep warm for 30 minutes, let stand for 12 hours, and filter;

[0031] (3) Add water, stir evenly, adjust the pH value to 6.0, add 0.5wt% activated carbon, stir fully, keep warm at 50°C for 30min, add ethanol, stir evenly, filter immediately, adjust the pH value of the filtrate to 1.5, and keep warm at 70°C 30min, let stand, filter, and wash the filter cake with 1 times the amount of pure water to obtain the walnut shell extract;

[0032] (4) Take fresh eggs, remove the frenulum, separate the egg white and e...

Embodiment 2

[0041] A preparation method of a composite microcapsule anti-ultraviolet finishing agent, the components are calculated in parts by weight, comprising the following steps:

[0042] (1) Collect walnut shells, pulverize after drying, add ethanol solution to extract for 45min, and collect the extract;

[0043] (2) Concentrate the extract to twice the weight of the walnut shell, refrigerate at low temperature for 16 hours, filter, adjust the pH value to 1.6, heat to 75°C, keep warm for 40 minutes, let stand for 16 hours, and filter;

[0044] (3) Add water, stir evenly, adjust the pH value to 6.5, add 0.6wt% activated carbon, stir fully, keep warm at 50°C for 30min, add ethanol, stir evenly, filter immediately, adjust the pH value of the filtrate to 1.7, and keep warm at 75°C 30min, let it stand, filter, and wash the filter cake with 1.5 times the amount of pure water to obtain the walnut shell extract;

[0045] (4) Take fresh eggs, remove the frenulum, separate the egg white and ...

Embodiment 3

[0054]A preparation method of a composite microcapsule anti-ultraviolet finishing agent, the components are calculated in parts by weight, comprising the following steps:

[0055] (1) Collect walnut shells, pulverize after drying, add ethanol solution to extract for 50min, and collect the extract;

[0056] (2) Concentrate the extract to twice the weight of the walnut shell, refrigerate at low temperature for 18 hours, filter, adjust the pH value to 1.8, heat to 75°C, keep warm for 45 minutes, let stand for 18 hours, and filter;

[0057] (3) Add water, stir evenly, adjust the pH value to 6.5, add 0.8wt% activated carbon, stir fully, keep warm at 50°C for 30min, add ethanol, stir evenly, filter immediately, adjust the pH value of the filtrate to 1.8, and keep warm at 75°C 30min, let it stand, filter, and wash the filter cake with 1.5 times the amount of pure water to obtain the walnut shell extract;

[0058] (4) Take fresh eggs, remove the frenulum, separate the egg white and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com