Preparation method of aspirin/chitosan modified carbon nanotube administration system

A carbon nanotube and aspirin technology, which is applied in the field of preparation of aspirin/chitosan modified carbon nanotube drug delivery system, can solve the problem of not completely inhibiting thromboxane platelet aggregation, hindering the wide application of aspirin, reducing the incidence of gastrointestinal bleeding, etc. problems, to achieve good research and development application prospects, good economic development potential, and the effect of a dense drug delivery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

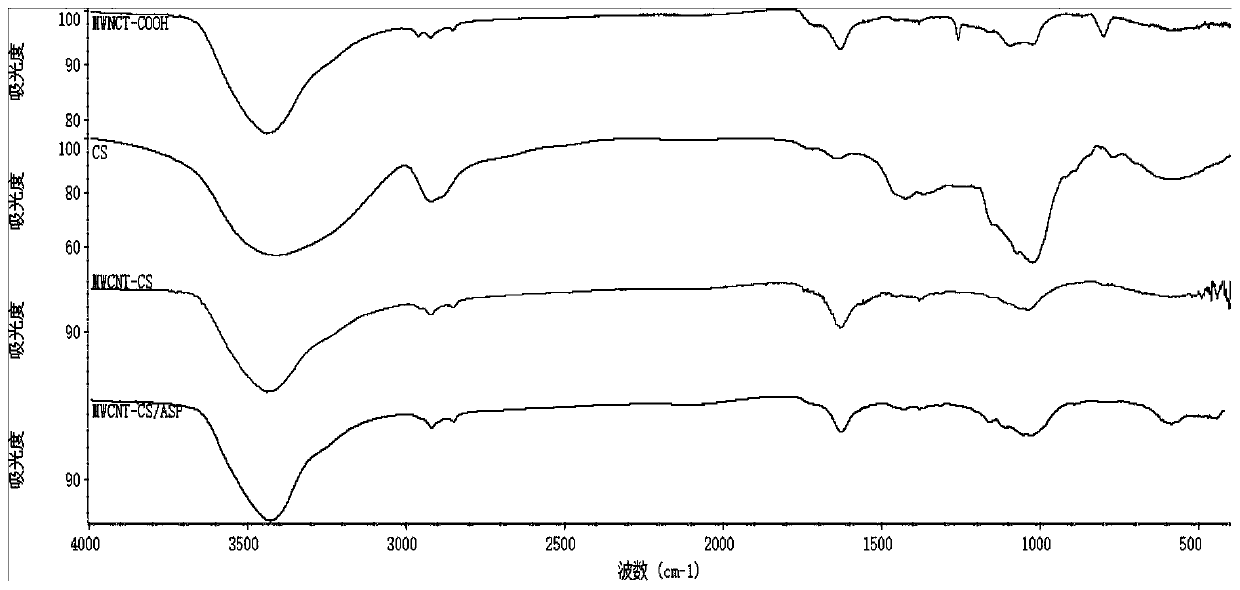

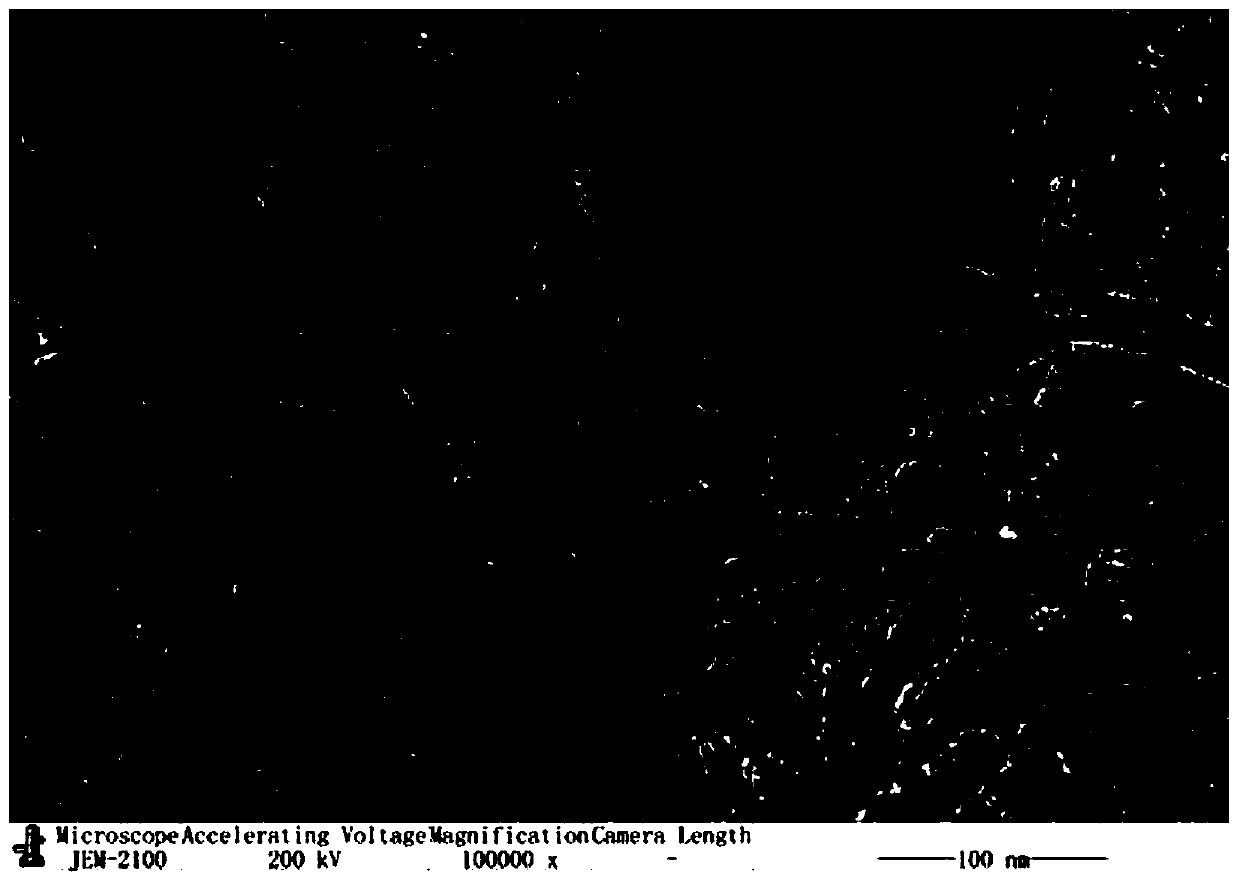

[0032]First mix concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 1:3, and then add multi-walled carbon nanotubes to the mixed acid with a mass / volume ratio of 5:1 under ultrasonic conditions. In the process, by controlling the ultrasonic parameters (ultrasonic power is 10w, ultrasonic time is 2s, interval time is 4s, and the number of ultrasonic waves is 60 times), the reaction temperature is 20°C, and the reaction time is 1h, the carboxylated multi-walled carbon nanotubes, concentrated sulfuric acid and concentrated Mixed acid of nitric acid, washed with water, filtered, and freeze-dried at -20°C for 24 hours, the product obtained is the active intermediate of multi-walled carbon nanotubes. Under the condition of ultrasound (ultrasonic power is 10w, ultrasonic time is 2s, interval time is 4s, and the number of ultrasonic waves is 60 times), the active intermediate of multi-walled carbon nanotubes is dissolved in deionized water containing catalyst E...

Embodiment 2

[0040] First mix concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 3:1, and then add single-walled carbon nanotubes to the mixed acid with a mass / volume ratio of 1:5 under ultrasonic conditions. In the process, by controlling the ultrasonic parameters (ultrasonic power is 50w, ultrasonic time is 4s, interval time is 7s, and the number of ultrasonic waves is 60 times), the reaction temperature is 50°C, and the reaction time is 1h, the carboxylated single-walled carbon nanotubes, concentrated sulfuric acid and concentrated Mixed acid of nitric acid, washed with water, filtered, and freeze-dried at -30°C for 36 hours, the product obtained is the active intermediate of single-walled carbon nanotubes. Under the condition of ultrasound (ultrasonic power is 50w, ultrasonic time 4s, interval time 7s, ultrasonic times 60 times), the single-walled carbon nanotube active intermediate is dissolved in deionized water containing catalyst DCC and HOBt with a mass ra...

Embodiment 3

[0042] First mix concentrated sulfuric acid and concentrated nitric acid in a volume ratio of 1:1, and then add multi-walled carbon nanotubes to the mixed acid with a mass / volume ratio of 2:3 under ultrasonic conditions. Among them, by controlling the ultrasonic parameters (ultrasonic power 100w, ultrasonic time 8S, interval time 10S, ultrasonic frequency 100 times), reaction temperature 100°C, and reaction time 5h, carboxylated multi-walled carbon nanotubes, concentrated sulfuric acid and concentrated nitric acid were obtained. The mixed acid was washed with water, filtered, and freeze-dried at -40°C for 48 hours to obtain the product, which is the active intermediate of multi-walled carbon nanotubes. Under the condition of ultrasonic ((ultrasonic power 100w, ultrasonic time 8S, interval time 10S, ultrasonic times 100 times), the active intermediate of multi-walled carbon nanotubes was dissolved in deionized water containing catalyst DIC and DMAP with a mass ratio of 1:3, Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com