A tetragonal phase (nh 4 ) 2 v 3 o 8 Preparation method of nanosheet and its application

A tetragonal phase and nanosheet technology, which is applied in the preparation and application of nanophotothermal materials, can solve the problems of difficult operation, difficult process control, complicated methods, etc., and achieves high operational accessibility, short reaction time, and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention has a tetragonal phase (NH 4 ) 2 V 3 o 8 A method for preparing nanosheets, comprising the following steps:

[0037] S1. Disperse the vanadium source in deionized water, magnetically stir and raise the temperature to completely dissolve the vanadium source to obtain solution A;

[0038] Among them, the vanadium source is NH 4 VO 3 , per 3 mmol of NH 4 VO 3 Add 15-20ml of deionized water, and the heating temperature is 100°C;

[0039] S2, keep warming and stirring, add the reducing agent into the solution A to obtain the mixed solution B;

[0040] Among them, the reducing agent is thioacetamide (TAA), every 3mmol of NH 4 VO 3 Add TAA to 12~24mmol, NH 4 VO 3 : The ratio of the molar ratio of TAA is 1:(4~8);

[0041] S3, keep stirring, and keep the mixed solution B at a specified temperature for a period of time to complete the crystal growth;

[0042] Wherein, the temperature is 150-250° C., and the time is 15-20 minutes;

[0043] S4, ...

Embodiment 1

[0051] First, inject 15mL of deionized water into a 50mL Erlenmeyer flask, mix 3mmol ammonium metavanadate in deionized water, and heat to 100°C to dissolve to obtain vanadium source solution A;

[0052] Then, the stirring was continued and the temperature was maintained at 100°C. Subsequently, 12 mmol TAA was added to make NH 4 VO 3 : The molar ratio of TAA is 1:4. Then raise the temperature to 150°C and keep it warm for 15 minutes to complete the growth of nanosheets, then stop heating, and cool the reaction system to room temperature;

[0053] Then, it was centrifuged at 9600r / min, washed twice with ethanol and deionized water, discarded the supernatant, and dried at 60°C for 6 hours to obtain a black powder, which was the target product.

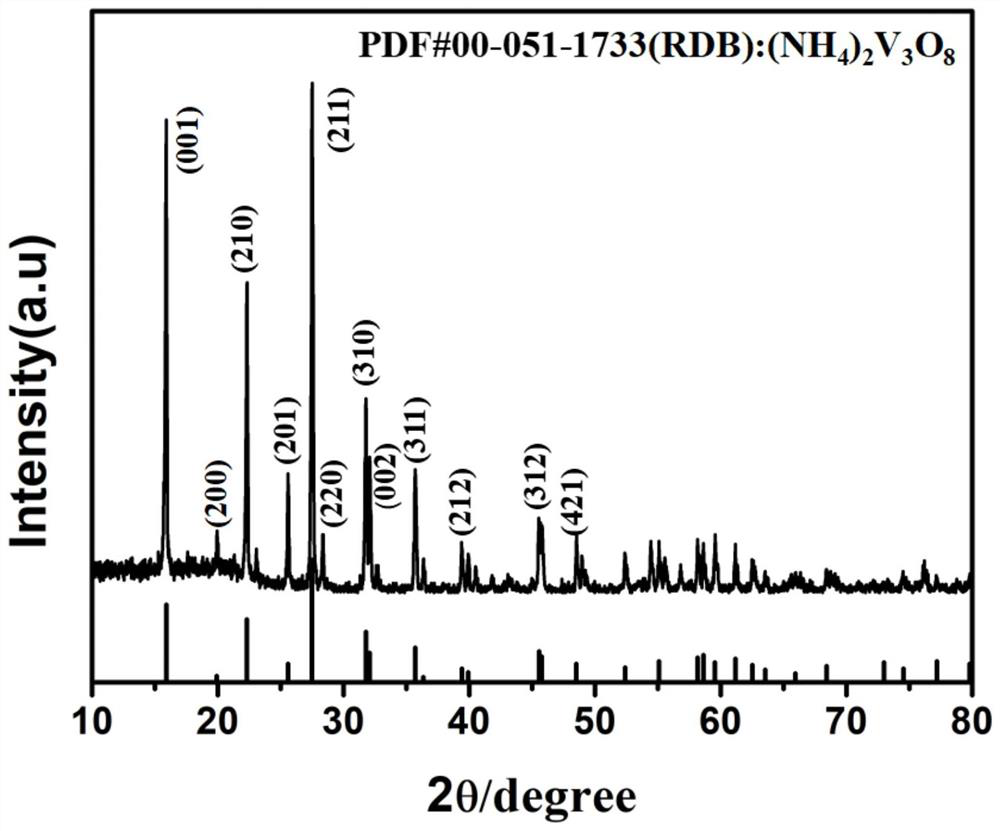

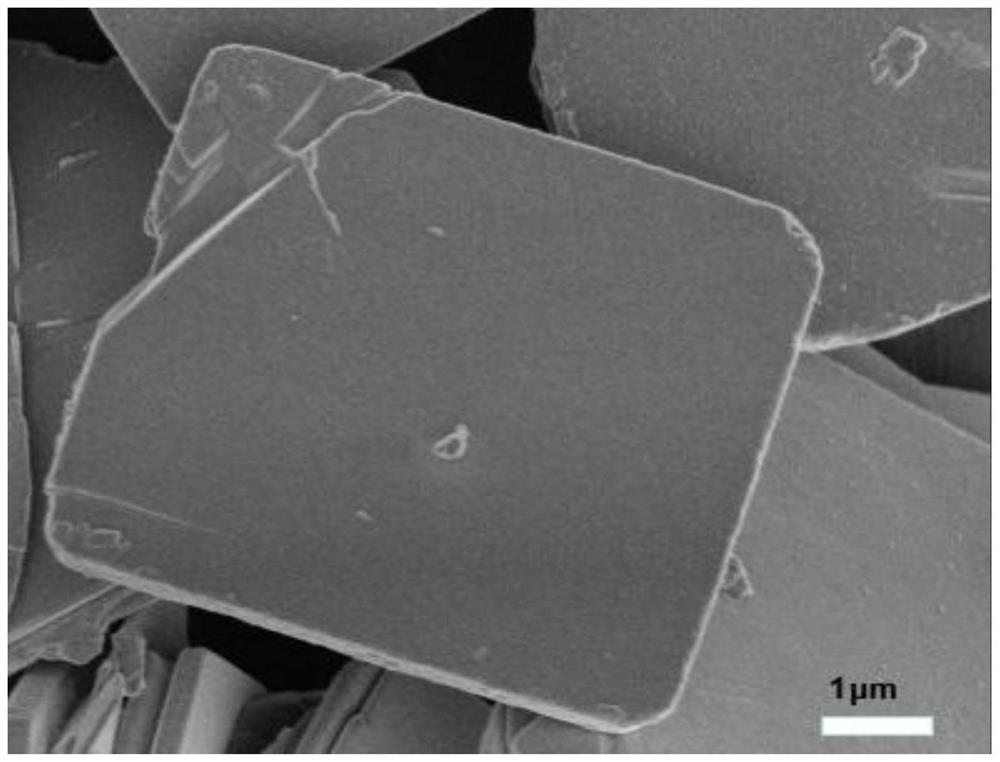

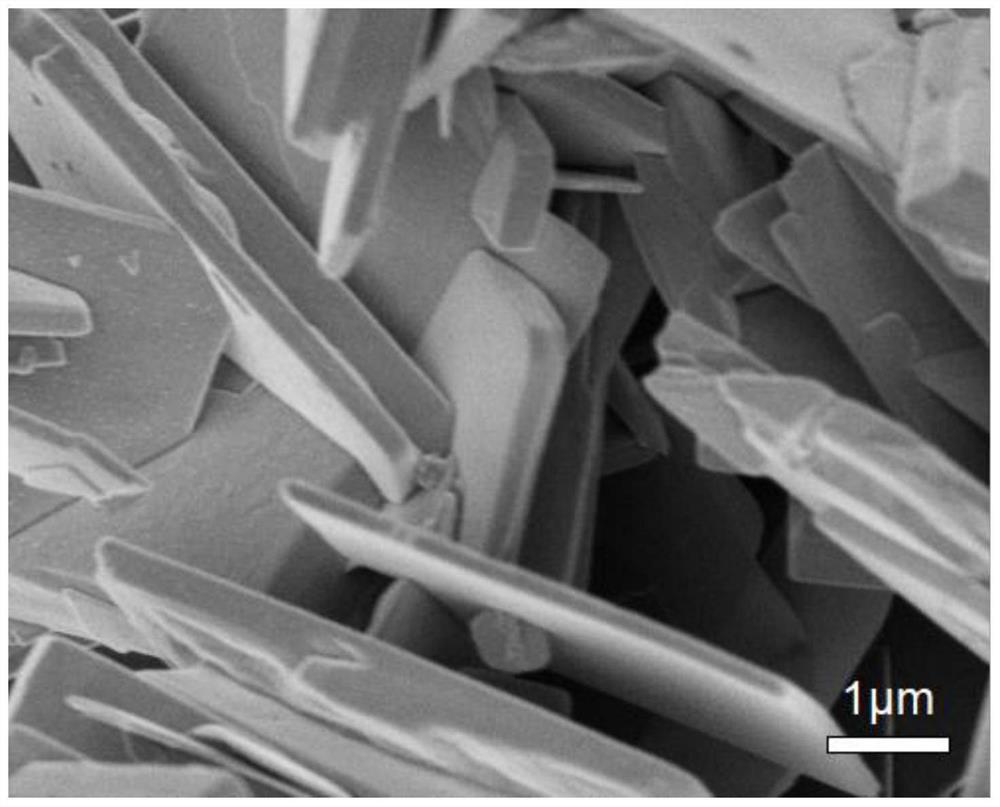

[0054] figure 1 It is the single crystal grown according to Example 1 (NH 4 ) 2 V 3 o 8 In the X-ray diffraction spectrum of nanosheets, almost no impurity peaks appear, indicating that the product is pure (NH 4 ) 2 V 3 o 8 ....

Embodiment 2

[0058] First, inject 17mL of deionized water into a 50mL Erlenmeyer flask, mix 3mmol ammonium metavanadate in deionized water, and heat to 100°C to dissolve to obtain vanadium source solution A;

[0059] Then, the stirring was continued and the temperature was maintained at 100°C. Subsequently, 15 mmol TAA was added to make NH 4 VO 3 : The molar ratio of TAA is 1:5, and then the temperature is raised to 200° C. and kept for 16 minutes to complete the growth of nanosheets, then the heating is stopped, and the reaction system is cooled to room temperature;

[0060] Finally, after centrifugation at 5600r / min, wash twice with ethanol and deionized water, discard the supernatant, and dry at 70°C for 4 hours to obtain a black powder, which is the target product.

[0061] Figure 5 It is the single crystal (NH 4 )2 V 3 o 8 In the X-ray diffraction spectrum of nanosheets, almost no impurity peaks appear to indicate that the product is pure (NH4) 2 V 3 o 8 .

[0062] Image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com