Preparation method of red photon glaze

A photonic and red technology, applied in the field of preparation of red photonic glaze, can solve the problems of difficulty in mass production, increase the uncontrollability of the glaze layer structure, low sintering temperature of the colloid system, achieve high refractive index contrast, and be easy to promote on a large scale , the effect of the vast commercial market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

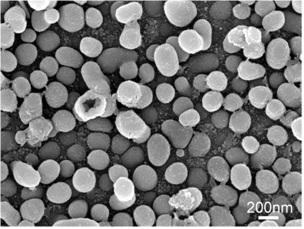

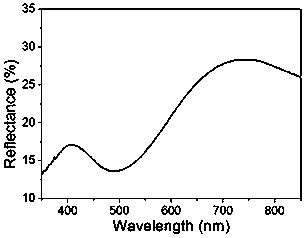

Image

Examples

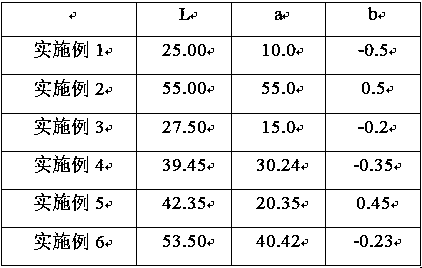

Embodiment 1

[0021] A preparation method of red photonic glaze, the concrete steps are:

[0022] (1) According to the mass percentage of material composition: kaolin 12.5%, quartz 16.5%, TiO 2 12.5%, limestone 14.5%, albite 15.5%, ZnO 18.5%, talc 10.0%;

[0023] (2) Put the raw materials in step (1) into a ball mill for 1 hour;

[0024] (3) Sieve the glaze slurry milled in step (2) to obtain a glaze slurry with a particle size of <45 μm, and the aging time is 24 hours;

[0025] (4) Applying the processed raw materials in step (3) to the surface of the green body;

[0026] (5) Dry the sample after glazing in step (4) at 60°C for 10 hours;

[0027] (6) Put the sample dried in step (5) into a high-temperature electric furnace for sintering, and then cool naturally with the furnace to obtain a bright red photonic glaze; ℃, the holding time is 30 minutes.

Embodiment 2

[0029] A preparation method of red photonic glaze, the concrete steps are:

[0030] (1) According to the mass percentage of material composition: kaolin 14.0%, quartz 12.5%, TiO 2 18.5%, limestone 9.0%, albite 26.0%, ZnO 12.5%, talc 7.5%;

[0031] (2) Put the raw materials in step (1) into a ball mill for 1 hour;

[0032] (3) Sieve the glaze slurry milled in step (2) to obtain a glaze slurry with a particle size of <45 μm, and the aging time is 24 hours;

[0033] (4) Applying the processed raw materials in step (3) to the surface of the green body;

[0034] (5) Dry the sample after glazing in step (4) at 60°C for 10 hours;

[0035] (6) Put the sample dried in step (5) into a high-temperature electric furnace for sintering, and then cool naturally with the furnace to obtain a bright red photonic glaze; the maximum temperature of the sintering process is 1300 ° C, the holding time is 90 minutes, and the ℃, the holding time is 30 minutes.

Embodiment 3

[0037] A preparation method of red photonic glaze, the concrete steps are:

[0038] (1) According to the mass percentage of material composition: kaolin 15.5%, quartz 15.0%, TiO 2 10.0%, limestone 16.5%, albite 16.5%, ZnO 17.5%, talc 9.0%;

[0039] (2) Put the raw materials in step (1) into a ball mill for 1 hour;

[0040] (3) Sieve the glaze slurry milled in step (2) to obtain a glaze slurry with a particle size of <45 μm, and the aging time is 24 hours;

[0041] (4) Applying the processed raw materials in step (3) to the surface of the green body;

[0042] (5) Dry the sample after glazing in step (4) at 60°C for 10 hours;

[0043] (6) Put the sample dried in step (5) into a high-temperature electric furnace for sintering, and then cool naturally with the furnace to obtain a bright red photonic glaze; ℃, the holding time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com