Preparation method of europium-doped strontium aluminate nanobelt with up-conversion luminescence property

A technology of luminescent properties and nanobelts, applied in the field of nanoluminescent materials, can solve problems such as limitation, achieve the effect of reducing droplets, avoiding the generation of impurities, and realizing green light up-conversion luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of the europium-doped strontium aluminate nanoribbon with up-conversion luminescence performance of the present invention comprises the following steps:

[0039] First, add aluminum nitrate and strontium nitrate into 4mL deionized water at a stoichiometric ratio of 1:2 until the raw materials are completely dissolved to obtain a transparent solution A; then compose SrAl according to the chemical formula 2 o 4 :xEu (x=0.01~0.05mol%) add dopant europium nitrate to A, the addition amount is 0.01~0.05mmol, then add 2~5mL ethanol, make it dissolve completely, the volume ratio of deionized water and ethanol 4: (2-5), to obtain a mixed solution precursor solution; then, add PVP with a mass ratio of 10% to 15%, and stir for several hours until the PVP is completely dissolved, and the solution becomes colorless and transparent with a certain viscosity. sex.

[0040] Then, turn on the electrospinning device, adjust the high voltage to 25-30kV, draw 2.5mL of...

Embodiment 1

[0044] First, weigh 0.211g Sr(NO 3 ) 3 , 0.75g Al(NO 3 ) 3 Add 4mL of deionized water to fully dissolve it, add 0.01mmol of europium nitrate to the solution, and then add 5mL of ethanol to obtain a precursor solution; weigh 10% PVP by weight, and wait until it dissolves into a transparent and viscous Colloid; start electrospinning, draw 2.5mL precursor solution with a syringe, set the receiving distance between the syringe needle and the collecting plate to 10cm, set the voltage to 25kV, and set the advancing rate to 15uL / min to obtain nanoribbons; Put the spun ribbon into the muffle furnace, set the holding time at 800°C for 3 hours, the heating rate at 4°C / min, the cooling rate at 4°C / min, and take it out after cooling to room temperature, which is the target product.

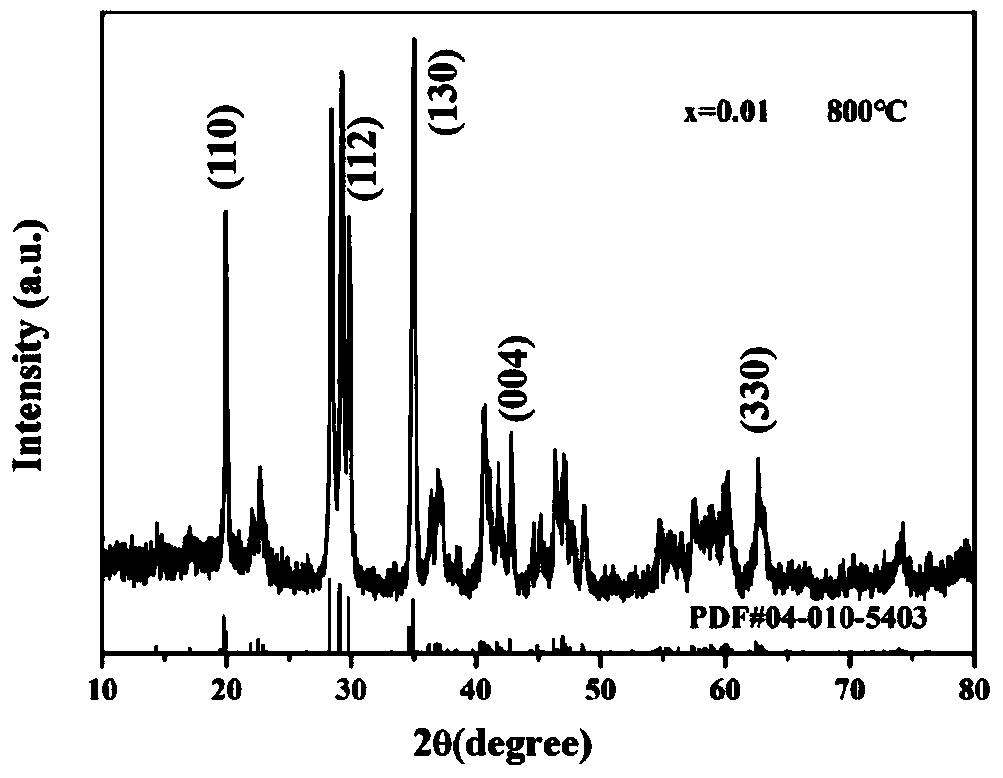

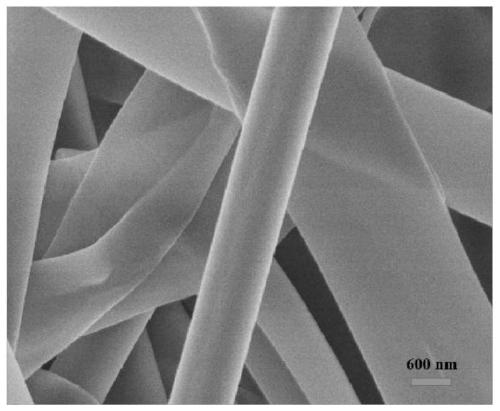

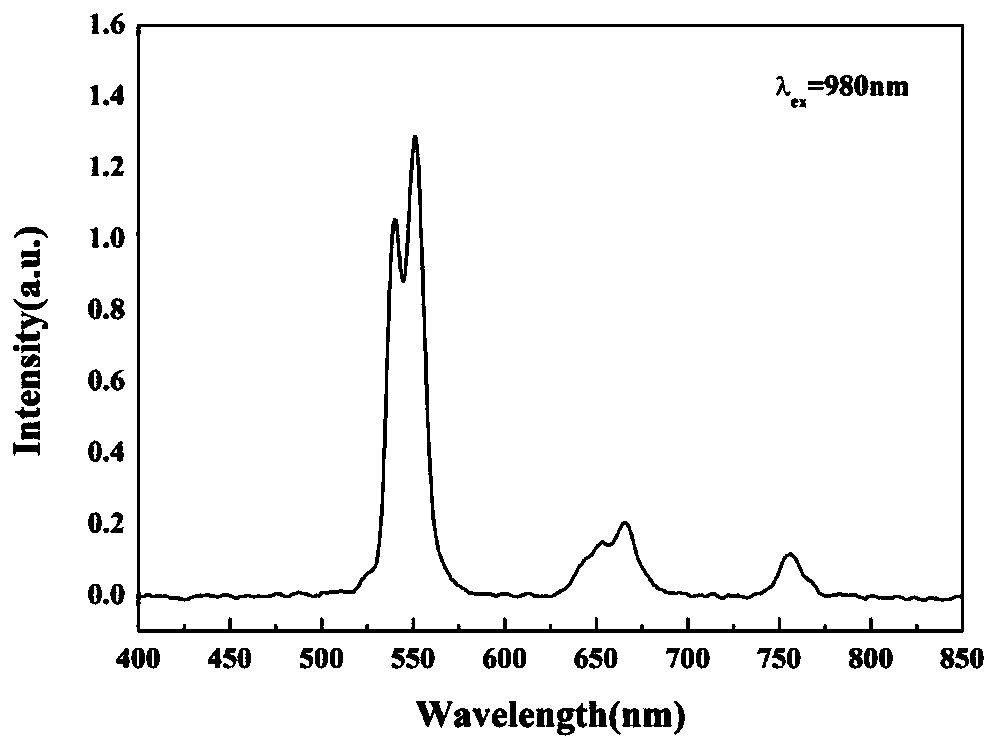

[0045] figure 1 It is the SrAl prepared according to Example 1 2 o 4 In the X-ray diffraction spectrum of the nanobelt, no impurity peaks appear, indicating that the product is pure SrAl 2 o 4 nanobel...

Embodiment 2

[0049] First, weigh 0.211g Sr(NO 3 ) 3 , 0.75g Al(NO 3 ) 3 Add 4 mL of deionized water to fully dissolve it, add 0.02 mmol of europium nitrate to the solution, and then add 4.5 mL of ethanol to obtain a precursor solution; weigh PVP with a mass ratio of 12%, and dissolve it until it becomes transparent and viscous Colloid; start electrospinning, extract 2.5mL precursor solution with a syringe, set the receiving distance between the syringe needle and the collecting plate to 12cm, set the voltage to 30kV, and set the advancing rate to 16ul / min to obtain nanobelts; Put the electrospun tape into the muffle furnace, set the holding time at 1000°C for 1 hour, the heating rate at 5°C / min, the cooling rate at 20°C / min, and take it out after cooling to room temperature, which is the target product.

[0050] Figure 4 It is the SrAl prepared according to Example 2 2 o 4 In the X-ray diffraction spectrum of the nanobelt, no impurity peaks appear, indicating that the product is pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com