Preparation device for low-stress SiC single crystal

A preparation device, low stress technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of large mismatch stress, proliferation, internal stress at the contact of seed crystal and crystal edge, etc. Good bending resistance and small elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

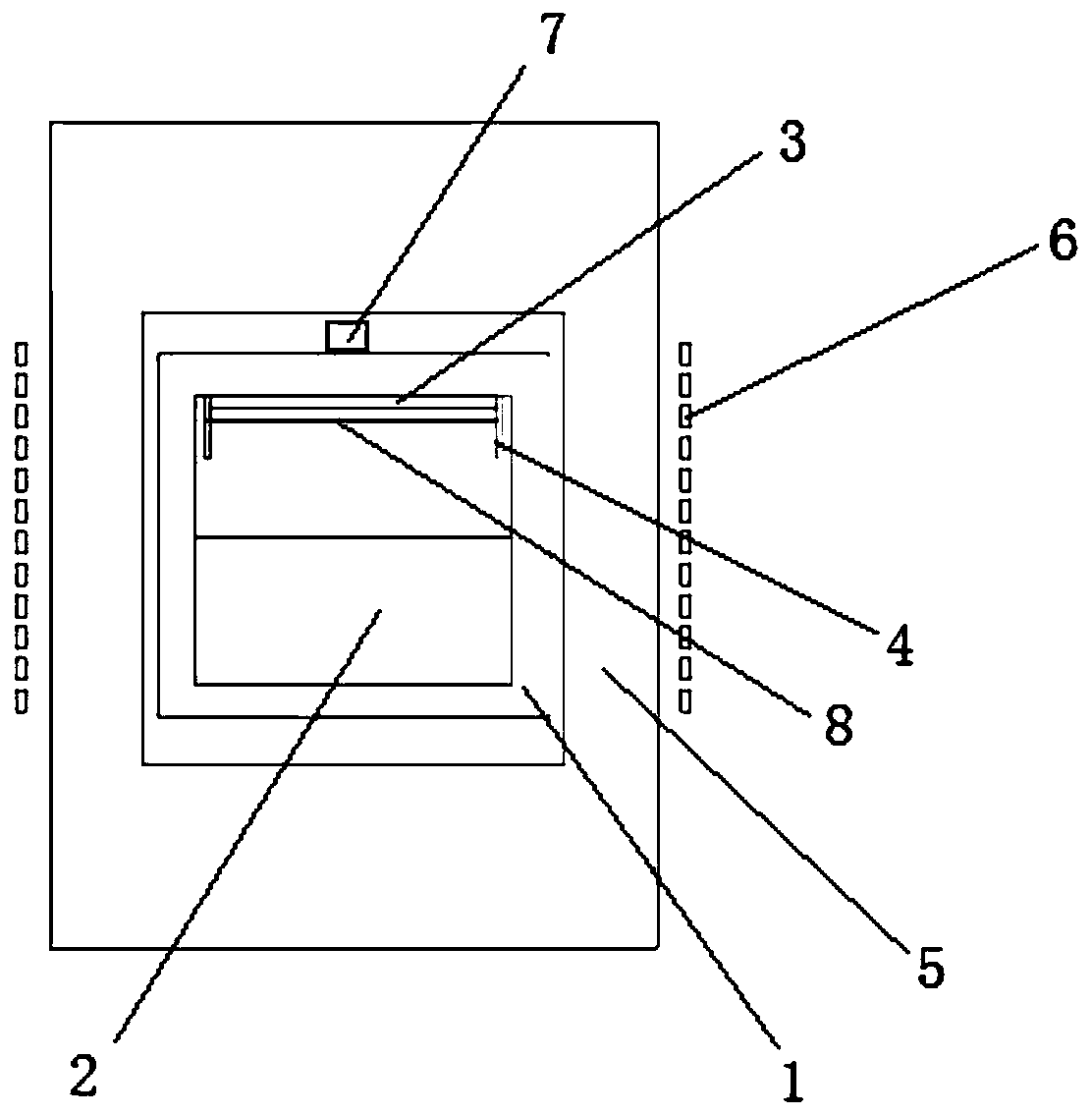

[0017] like figure 1 As shown, a low-stress SiC single crystal preparation device includes a graphite crucible 1, the bottom of which is equipped with SiC raw material 2, and the inside of the upper cover of the crucible 1 is fixed with a stress buffer layer 3 made of a high-temperature-resistant flexible material. The seed crystal 8 is bonded on the stress buffer layer 3, and a stress buffer ring 4 made of a high-temperature-resistant flexible material for limiting the diameter of the crystal is arranged next to the seed crystal outside the seed crystal 8, and the outer peripheral side of the graphite crucible 1 is provided with A thermal insulation layer 5 with high temperature resistance and low thermal conductivity, an induction coil 6 made of metal material is wound around the outer peripheral side of the thermal insulation layer 5, an infrared temperature measuring probe 7 is arranged on the top of the graphite crucible 1, and the infrared temperature measuring probe 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com