Hydrophilic coating solution for intervention catheter, preparation method and use method thereof

A technology for hydrophilic coatings and interventional catheters, applied in catheters, coatings, pharmaceutical formulations, etc., can solve the problems of loss of hydrophilic lubrication of the coating system, lack of adhesion of interventional catheters, insufficient wear resistance of coatings, etc., to achieve Excellent hydrophilicity, solve the effect of insufficient firmness, and increase the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the hydrophilic coating solution for the above-mentioned interventional catheter comprises the following steps:

[0047] Add organic solvent, deionized water and hydrophilic compound into the container, stir at room temperature until the hydrophilic compound is completely dissolved; then add acrylate compound, surfactant and citrate plasticizer, stir for 30-60min; then add light Initiator, stir until the solution is clear, that is, too.

[0048] The method for using the hydrophilic coating solution for the above-mentioned interventional catheter comprises the following steps:

[0049] Coating step: coating the hydrophilic coating solution on the surface of the intervention catheter by dipping, spraying or brushing;

[0050] Steps of UV curing: placing the interventional catheter after the coating step under ultraviolet light with an irradiance of 5-100mW / cm2, and curing for 100-300s to obtain an interventional catheter with a hydrophilic coati...

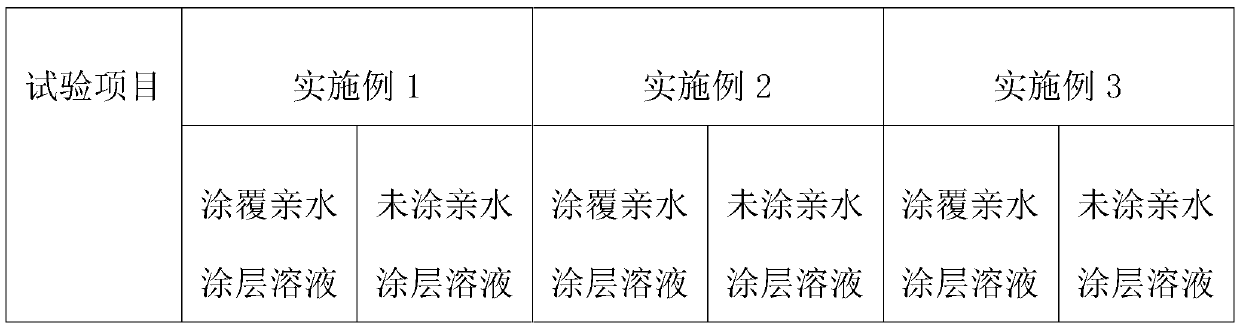

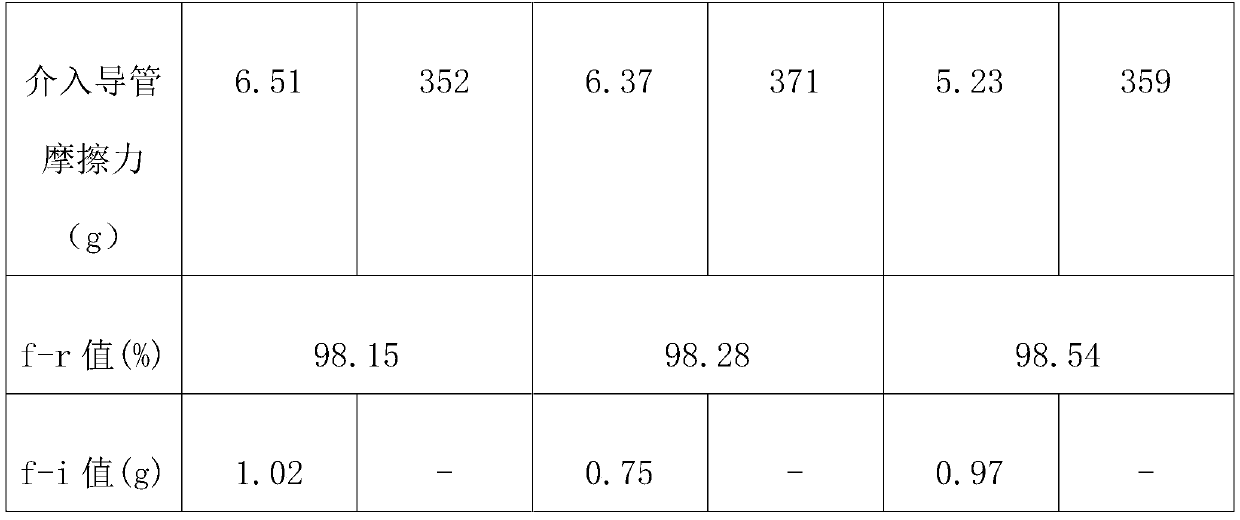

Embodiment 1

[0052] A hydrophilic coating solution for interventional catheters. Take 2.5 g of polyvinylpyrrolidone with a molecular weight of 500,000 Daltons, 85 g of absolute ethanol, and 12.3 g of deionized water in a container, stir at room temperature, The pyrrolidone was completely dissolved. Add 0.5g of a mixture of ethylene glycol diacrylate and polyethylene glycol diacrylate, 0.05g of polyether-terminated polysiloxane, 0.1g of acetyl tributyl citrate, continue stirring for 30min, and then add 1-hydroxy Cyclohexyl phenyl ketone 0.05g, stirred to a transparent and clear state, that is.

[0053] The method for using the hydrophilic coating solution for the above-mentioned interventional catheter comprises the following steps:

[0054] Coating step: coating the hydrophilic coating solution on the surface of the interventional catheter by means of dip coating;

[0055] The step of ultraviolet light curing: the interventional catheter after the coating step is placed under the ultravi...

Embodiment 2

[0057] A hydrophilic coating solution for interventional catheters. Take 3 g of polyvinylpyrrolidone with a molecular weight of 500,000 Daltons, 80 g of isopropanol, and 15.92 g of deionized water in a container, and stir at room temperature until the polyvinyl pyrrolidone Pyrrolidone dissolved completely. Add 0.9 g of a mixture of propoxylated glycerol triacrylate, ethylene glycol diacrylate and polyethylene glycol diacrylate, 0.1 g of polydimethylsiloxane, 0.1 g of acetyl tributyl citrate, Continue stirring for 60 min, then add 0.08 g of a mixture of 1-hydroxycyclohexyl phenyl ketone and 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-propanone, and stir until transparent and clear Status, that is.

[0058] The method for using the hydrophilic coating solution for the above-mentioned interventional catheter comprises the following steps:

[0059] Coating step: coating the hydrophilic coating solution on the surface of the interventional catheter by brushing;

[0060] Steps...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap