ASA emulsifying device and control method

An emulsifying device and control method technology, applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problem of prone to hydrolysis, alcoholysis and ammonolysis, high maintenance cost of regenerative turbo pump, interference with sizing agent application. It can improve the emulsification effect, retention performance and anti-anion interference performance, and improve the emulsification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

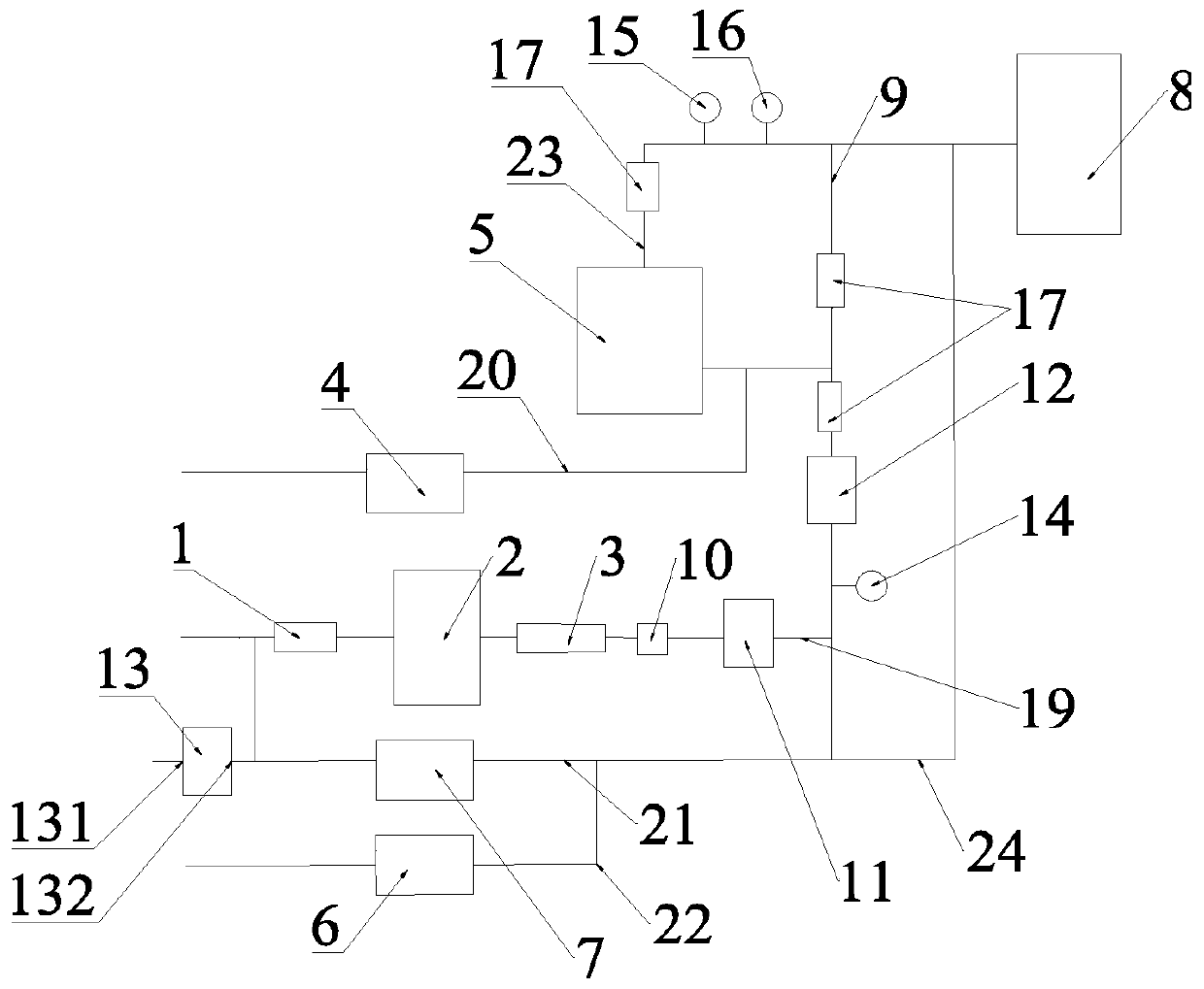

[0040] refer to figure 1 , figure 2 As shown, a kind of ASA emulsification device comprises water treatment device 13, emulsifier pretreatment device, emulsification equipment and controller;

[0041] Described water treatment device 13 comprises water treatment tank inlet 131 and water treatment tank outlet 132, and described water treatment tank outlet is connected with emulsifier pretreatment device and emulsification equipment through tee; Described water treatment device 13 is ion exchange Resin box;

[0042] The emulsifier pretreatment device includes a first static mixer 1, a reactor 2, and a second static mixer 3 connected in series in sequence, the inlet of the first static mixer 1 is connected to the outlet 132 of the water treatment tank, and the first The outlet of the static mixer 1 is connected to the reactor 2; the reactor 2 is also connected to a second static mixer 3; the outlet of the second static mixer 3 is connected to the emulsifier pump 10 of the emul...

Embodiment 2

[0054] The difference between this embodiment and embodiment 1 is that the specific steps of the method for controlling emulsification of ASA are as follows:

[0055] Step 1, water pretreatment: water enters the water treatment device from the inlet of the water treatment tank, and the water whose hardness is reduced by ion exchange resin is pumped out from the outlet of the water treatment tank, and then pumped into the emulsifier pretreatment device and emulsification equipment through the water pump ;

[0056] Step 2, emulsifier pretreatment, the emulsifier is pre-filled in the first static mixer, and the emulsifier is an amphiphilic emulsifier; the pretreated water is mixed with the emulsifier through the first static mixer, Entering the reactor under water drive; the emulsifier aqueous solution after the reaction enters the emulsifier pump from the second static mixer, and the emulsifier is processed into an emulsifier aqueous solution;

[0057] Step 3, emulsifier treatm...

Embodiment 3

[0063] The difference between this embodiment and embodiment 1 is that the specific steps of the method for controlling emulsification of ASA are as follows:

[0064] Step 1, water pretreatment: water enters the water treatment device from the inlet of the water treatment tank, and the water whose hardness is reduced by ion exchange resin is pumped out from the outlet of the water treatment tank, and then pumped into the emulsifier pretreatment device and emulsification equipment through the water pump ;

[0065] Step 2, emulsifier pretreatment, the emulsifier is pre-filled in the first static mixer, and the emulsifier is an amphiphilic emulsifier; the pretreated water is mixed with the emulsifier through the first static mixer, Entering the reactor under water drive; the emulsifier aqueous solution after the reaction enters the emulsifier pump from the second static mixer, and the emulsifier is processed into an emulsifier aqueous solution;

[0066] Step 3, emulsifier treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com