Preparation method for high-density copper azide with constrained shell

A copper azide, high-density technology, applied in the field of pyrotechnics, can solve the problems of weakened detonation capability, inability to meet the requirements of MEMS fuze high-density detonators, and low product density, and achieves low equipment requirements and safe preparation process. Green, pollution-free, simple preparation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Example 1: Preparation of high-density copper-containing azide with constrained shell

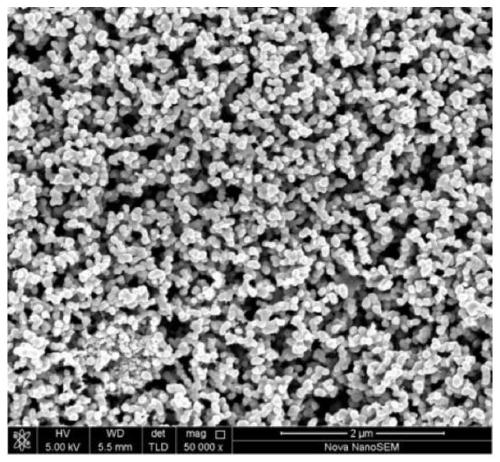

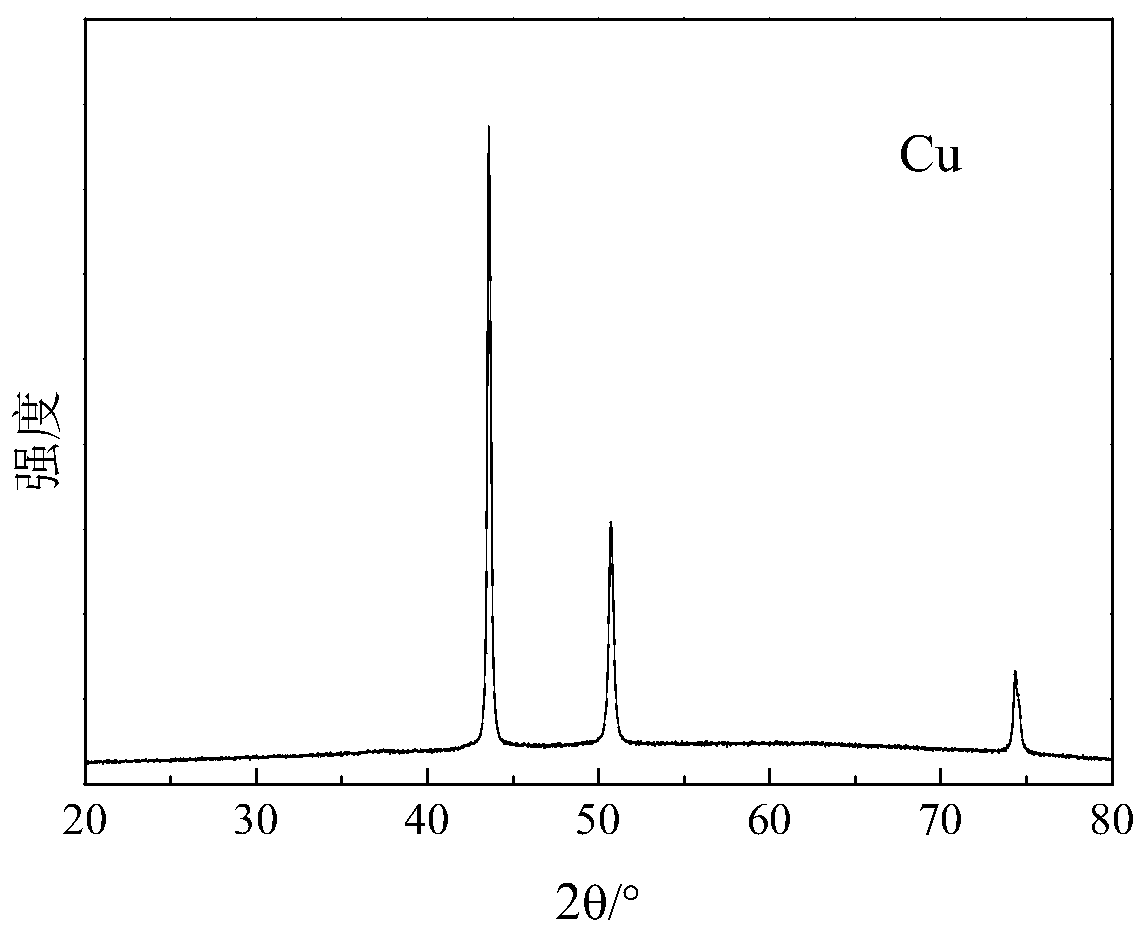

[0079] Take 2g of oxalic acid and 1g of copper nitrate and grind them for 60min, put them in a tube furnace, raise the temperature to 550°C under the protection of nitrogen, keep it warm for 150min, and get nanoporous copper after cooling. figure 1 The SEM characterization figure of the nanoporous copper prepared for this embodiment, by figure 1 It can be seen that the nanoporous copper particles are uniform, the particle size is about 100nm, and there are a lot of pores. figure 2 The XRD characterization pattern of the nanoporous copper prepared for this example completely matches the standard pattern of copper (JCPDS No. 04-0836), without any impurity peaks, indicating that the final product is pure copper.

[0080] Transfer nanoporous copper into a confinement shell with a thickness of 0.4mm and a through hole diameter of 0.8mm. The density of nanoporous copper in the confinem...

Embodiment 2

[0081] Example 2: Preparation of high-density copper-containing azide with constrained shell

[0082] Dissolve 1g of oxalic acid and 0.5g of copper nitrate in 10mL of absolute ethanol respectively, mix the two solutions for 30 minutes, remove the solvent by centrifugation or filtration, dry the solid or directly raise the temperature to 450°C under the protection of nitrogen and keep it warm for 120 minutes, then cool After obtaining nanoporous copper;

[0083] Transfer nanoporous copper into a confinement shell with a thickness of 0.4mm and a through hole diameter of 0.8mm. The density of nanoporous copper in the confinement shell is about 1.5g / cm 3 .

[0084] The nanoporous copper monolith with a constrained shell was placed in a reactor for gas-solid in-situ chemical reaction with azide gas for 24 hours. After the reaction, the packing density of the bound shell is about 2.3g / cm 3 The mass of copper azide in this single confined shell is about 0.46mg.

[0085] Figure ...

Embodiment 3

[0086] Example 3: Preparation of high-density copper-containing azide with constrained shell

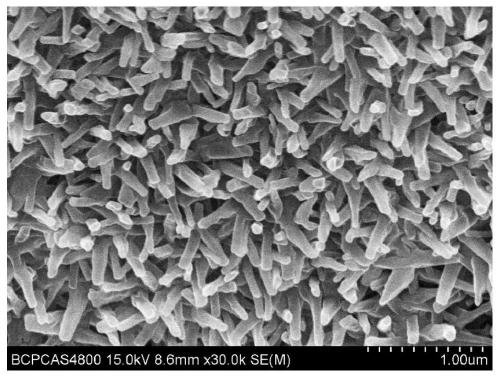

[0087] Dissolve 2 g of oxalic acid and 1 g of copper nitrate in 10 mL of anhydrous methanol respectively. After the two solutions are mixed, slowly evaporate the solvent to dryness. nanoporous copper oxide, Figure 7 The XRD spectrum characterization figure of the nanoporous copper oxide prepared for this example, the peaks at 35.46°, 38.64° and 48.70° in the spectrum correspond to (11-1), (111) and (20-2 ) crystal plane, the peaks in all spectra are completely matched with the peak positions in the CuO standard card (JCPDS No.48-1548), and there are no impurity peaks, indicating that copper oxalate solid powder can be sintered in air to obtain pure CuO. Transfer nanoporous copper oxide into a confinement shell with a thickness of 0.4mm and a diameter of 0.8mm, and the density of nanoporous copper in the confinement shell is about 1.6g / cm 3 . And placed in the reactor to carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com