Method for producing biogas through two-phase anaerobic fermentation of piggery wastewater

A pig farm wastewater and anaerobic fermentation technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, animal husbandry wastewater treatment, etc., can solve the problem of high operating cost of shock load, low gas production and gas production efficiency, organic matter Low degradation efficiency and other issues, to achieve strong adaptability and buffering effect, improve gas production and gas production efficiency, good economic benefits and project prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

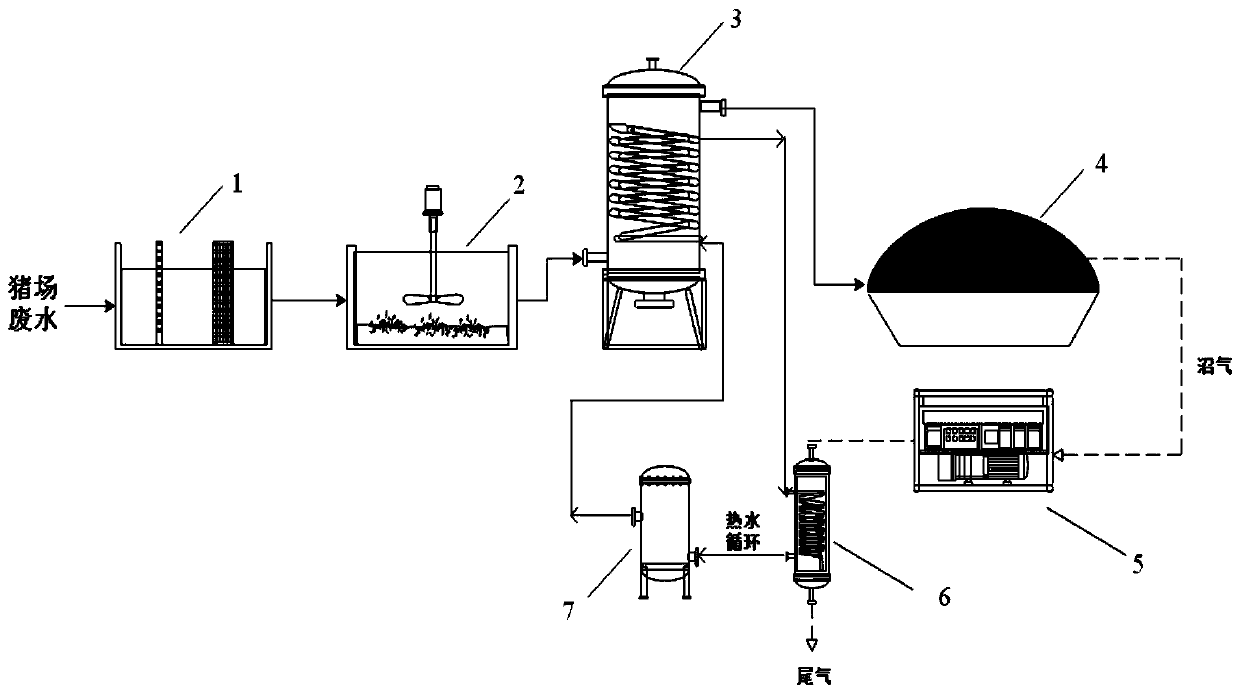

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

[0030] the case

[0031] A method for two-phase anaerobic fermentation of pig farm wastewater to produce biogas, comprising the following steps:

[0032] The pig farm wastewater enters the grid pool 1, and first passes through the coarse grid with a gap of 50mm to remove large debris in the wastewater, such as plastic bags, and then passes through the grid with a mesh size of 10mm to intercept small debris in the wastewater. such as gravel, etc.;

[0033] Preferably, the pig farm waste water enters the adjustment tank 2 by itself to form a uniform mixed solution. The adjustment tank 2 is equipped with a stirrer, the stirring speed is 150r / min, and the hydraulic retentio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com