Long-acting and weather-proof resin tile co-extrusion material with light screening function and preparation method thereof

A technology for light shielding and resin tiles, which is applied in the field of long-term weather-resistant resin tile co-extrusion and its preparation, can solve the problems of reducing the mechanical properties of materials, failing to effectively improve the anti-ultraviolet aging performance of ASA, and poor anti-ultraviolet aging properties, etc. Long life, excellent anti-ultraviolet aging performance, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

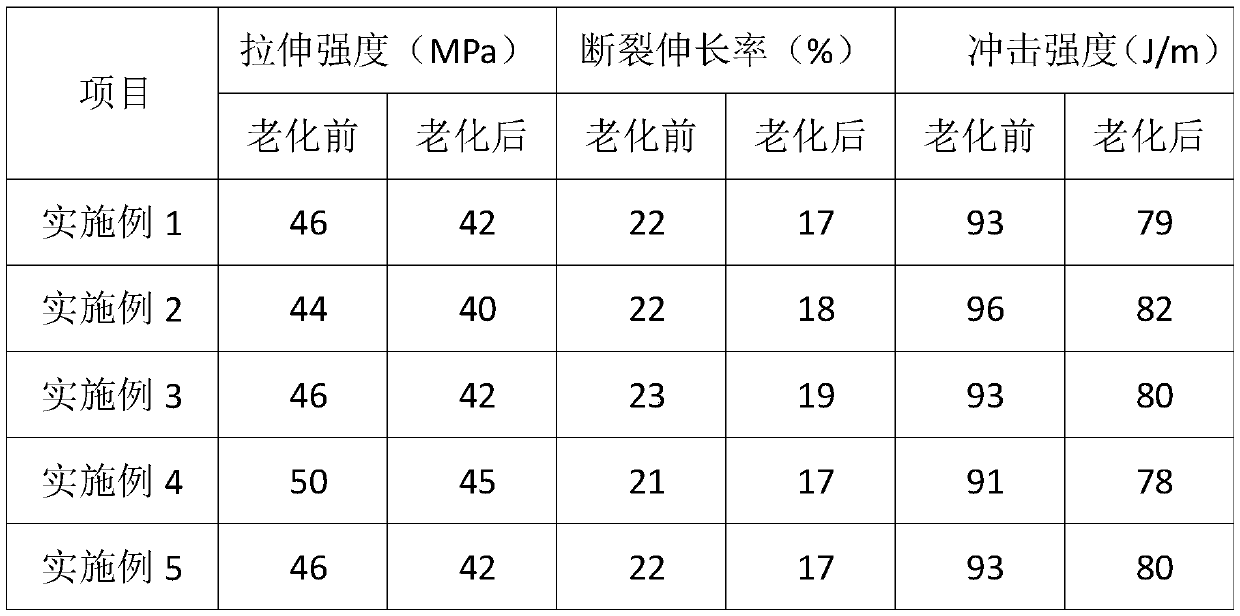

Examples

Embodiment 1

[0026] A long-acting weather-resistant resin tile co-extrusion material with light shielding function, characterized in that its raw materials include by weight: 65 parts of ASA resin, 20 parts of AS resin, 5 parts of modified montmorillonite, carbon black, nano-titanium dioxide 5 parts, UV-944 0.5 parts, salicylate 0.3 parts, antioxidant 1010 0.2 parts, EBS 0.5 parts, toner 3.5 parts.

[0027] Wherein, the modified montmorillonite is prepared by the following steps: dissolving sodium hexametaphosphate in water to form a homogeneous solution with a mass concentration of 1.2%, and then adding montmorillonite to obtain a suspension with a montmorillonite content of 0.3 g / ml; After the suspension is ultrasonically dispersed and stratified, the supernatant is vacuum spray-dried at 100°C to obtain a prefabricated material; the prefabricated material is dissolved in toluene, heated to boiling, and the treatment agent KH-570 is added dropwise, and stirred React for 4 hours, filter, w...

Embodiment 2

[0029] A long-acting weather-resistant resin tile co-extrusion material with light shielding function is characterized in that its raw materials include by weight: 65 parts of ASA resin, 20 parts of AS resin, 5 parts of modified montmorillonite, 5 parts of nano-titanium dioxide, 0.6 parts of UV-622, 0.4 parts of benzotriazoles, 0.5 parts of antioxidant 168, 0.5 parts of EBS, 3 parts of toner.

[0030] Wherein, the modified montmorillonite is prepared by the following steps: dissolving sodium hexametaphosphate in water to form a homogeneous solution with a mass concentration of 1.6%, and then adding montmorillonite to obtain a suspension with a montmorillonite content of 0.6 g / ml; Ultrasonic dispersion treatment of the suspension, standing and layering, taking the supernatant and vacuum spray drying at 110°C to obtain a preform; dissolving the preform in toluene, raising the temperature and adding the treatment agent KH-570 dropwise, and stirring for 9 hours , and filtered, was...

Embodiment 3

[0032] A long-acting weather-resistant resin tile co-extrusion material with light shielding function is characterized in that its raw materials include by weight: 75 parts of ASA resin, 15 parts of AS resin, 3.5 parts of modified montmorillonite, 3 parts of carbon black, UV-770, 0.5 parts, 0.3 parts of substituted acrylonitrile, 0.2 parts of antioxidant 1076, 0.1 parts of EBS, 2 parts of toner.

[0033] Wherein, the modified montmorillonite is prepared by the following steps: dissolving sodium hexametaphosphate in water to form a homogeneous solution with a mass concentration of 1.4%, and then adding montmorillonite to obtain a suspension with a montmorillonite content of 0.45 g / ml; Ultrasonic dispersion treatment of the suspension, standing and layering, taking the supernatant and vacuum spray drying at 105°C to obtain a prefabricated material; dissolving the prefabricated material in toluene, raising the temperature and adding treatment agent KH-570 dropwise, and stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com