An enhanced hydration separation using porous particles 4 /co 2 Methods

A porous particle, hydration separation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as clogged beds and nozzles, increase output value, increase mass transfer area, prevent clogged beds and The effect of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

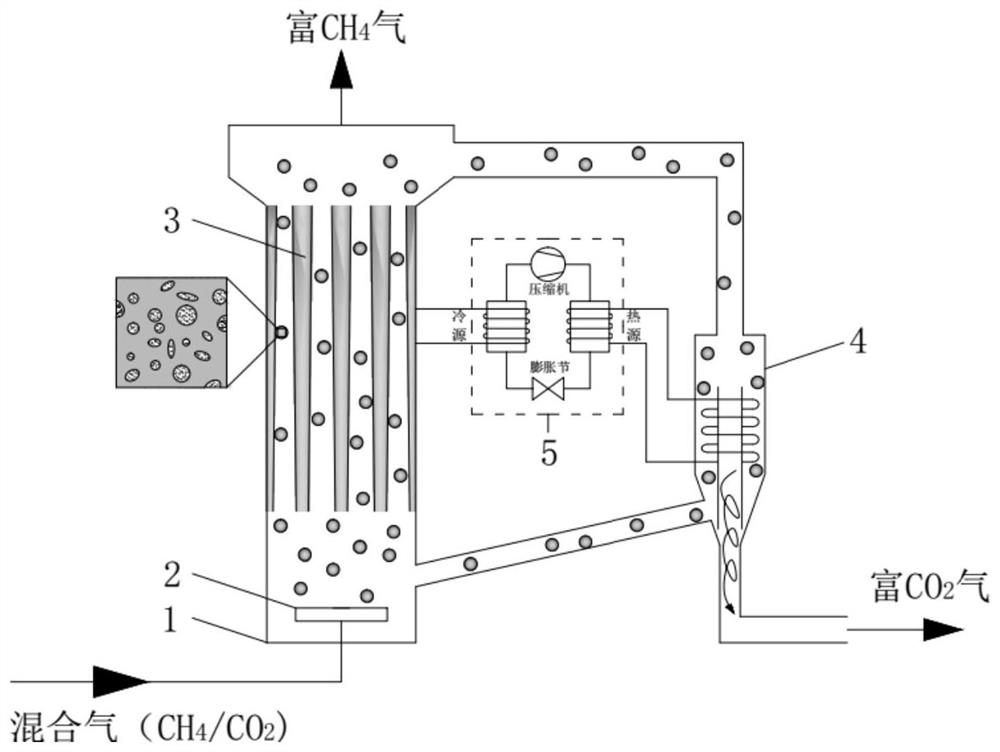

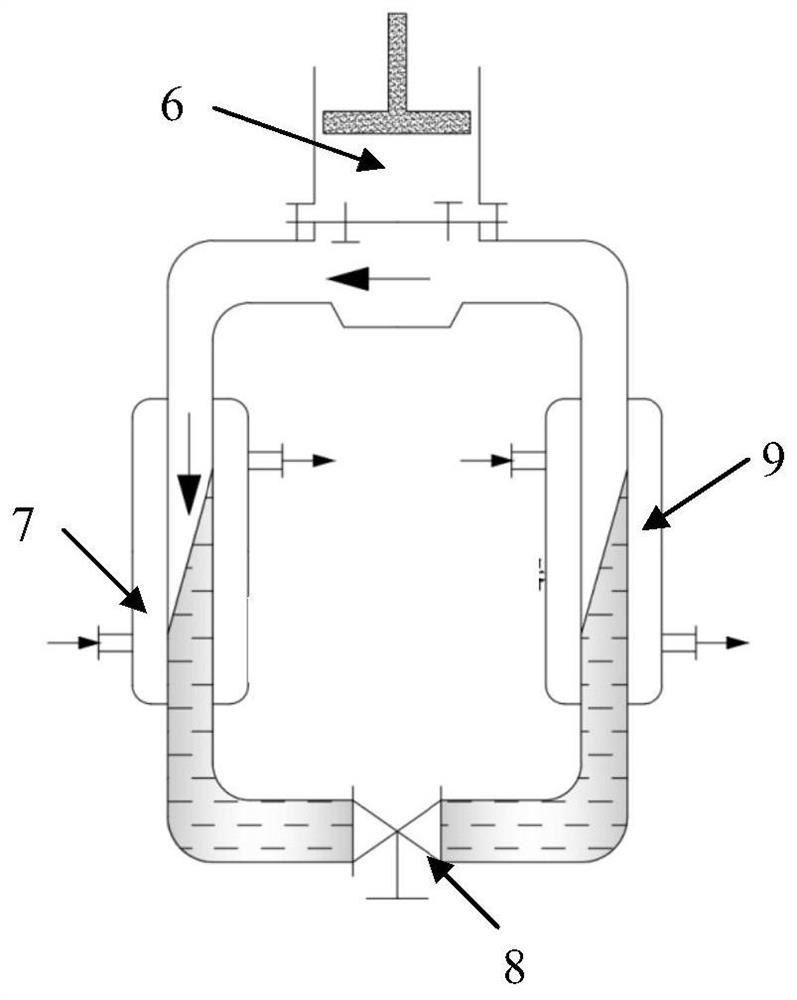

Method used

Image

Examples

Embodiment 1

[0030] This embodiment adopts the above-mentioned device. Among them, the hydrophobic foam metal is selected as the porous particle, the aqueous solution is pure water, and the mixed gas component is CH 4 / CO 2 (where CH 4 Volume content 67%). In this system, firstly, 3kg of aqueous solution is mixed with 0.1kg of hydrophobic silicon dioxide, and dry water is obtained after high-speed shearing, which is then filled into hydrophobic metal foam. 5 kg of porous granules are added. Set the mixed flow rate to 100m / h. Ethylene glycol aqueous solution is the cold source medium, and pure aqueous solution is the heat source medium. Adjust the fluidized bed temperature. The operating temperature of the fluidized bed reactor was set at 0.4°C, and the operating temperature of the cyclone separator was set at 25°C. The operating pressure is 5.66MPa. At this time CH 4 Enriched in the gas phase, hydrates are decomposed in the cyclone separator, CO 2 Precipitation, porous particles ...

Embodiment 2

[0032] This embodiment adopts the above-mentioned device. Among them, carbon nanotubes are selected as porous particles, pure water is selected for aqueous solution, and CH is selected for mixed gas components. 4 / CO 2 (where CH 4 Content 50%). In this system, first put the carbon nanotubes into the aqueous solution, and let them stand for 5 hours at 0° C. in an atmosphere of 2 MPa to prepare porous particles with a water content of 80%. 2 kg of prepared porous granules are added. Set the mixed flow rate to 185m / h. Ethylene glycol aqueous solution is the cold source medium, and pure aqueous solution is the heat source medium. Adjust the fluidized bed temperature. The operating temperature of the fluidized bed reactor was set at 0.4°C, and the operating temperature of the cyclone separator was set at 25°C. The operating pressure is 5.66MPa. At this time CH 4 Enriched in the gas phase, hydrates are decomposed in the cyclone separator, CO 2 Precipitation, porous particl...

Embodiment 3

[0034] This embodiment adopts the above-mentioned device. Among them, hydrophobic foamed aluminum is selected as the porous particle, and 0.12wt% [BMIm] BF is selected for the aqueous solution 4 (1-butyl-3-methylimidazolium tetrafluoroborate) + 5wt% TBAB, the mixed gas component selects CH 4 / CO 2 (where CH 4 Content 50%). In this system, first put 0.5kg of hydrophobic aluminum foam into the aqueous solution, and let it stand in an atmosphere of 2MPa at 0°C for 6h to prepare porous particles with a water content of 80%. 2.5 kg of porous granules are added. Set the mixed flow rate to 120m / h. Ethylene glycol aqueous solution is the cold source medium, and pure aqueous solution is the heat source medium. Adjust the fluidized bed temperature. The operating temperature of the fluidized bed reactor was set at 0.4°C, and the operating temperature of the cyclone separator was set at 25°C. The operating pressure is 4MPa. At this time CH 4 Enriched in the gas phase, hydrates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com